23

EN

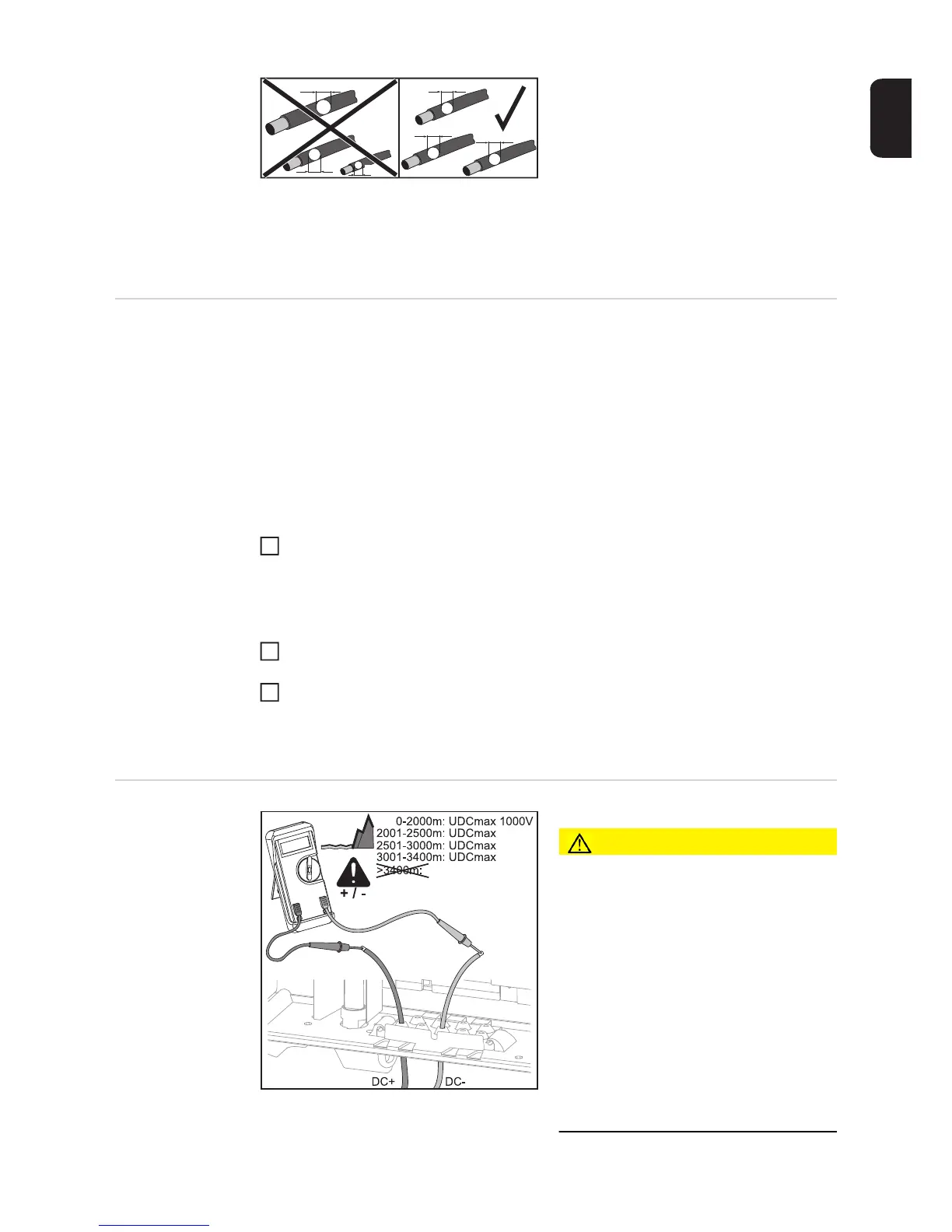

Note! To ensure effective strain relief of the

solar module strings, only use cables with

identical cross-sections.

IMPORTANT! When using ferrules for DC cables with a cross-section of 16 mm², the fer-

rules must be crimped with a right-angled cross-section.

The use of ferrules with insulating collars is only permitted up to a max. cable cross-section

of 10 mm².

Connecting alu-

minium cables

The DC-side terminals are suitable for connecting single-wire, round aluminium cables.

Because of the formation of a non-conductive oxide layer due to the reaction of aluminium

with air, the following points must be considered when connecting aluminium cables:

- the reduced rated currents for aluminium cables

- the connection conditions listed below

Note! Always follow the cable manufacturer instructions when using aluminium cables.

Note! When designing cable cross-sections, take local regulations into account.

Connection conditions:

Carefully clean the oxide layer from the bare end of the cable by scraping it, e.g. with

a knife

IMPORTANT! Do not use brushes, files or emery paper, as the aluminium particles get

trapped and can be transferred to other conductors.

Once the oxide layer is removed, rub the end of the cable with a neutral grease, such

as non-acidic and non-alkaline Vaseline

Immediately connect the cable end to the terminal

IMPORTANT! Repeat the procedure if the cable has been disconnected and is to be re-

connected.

Connecting solar

module strings to

the inverter (DC)

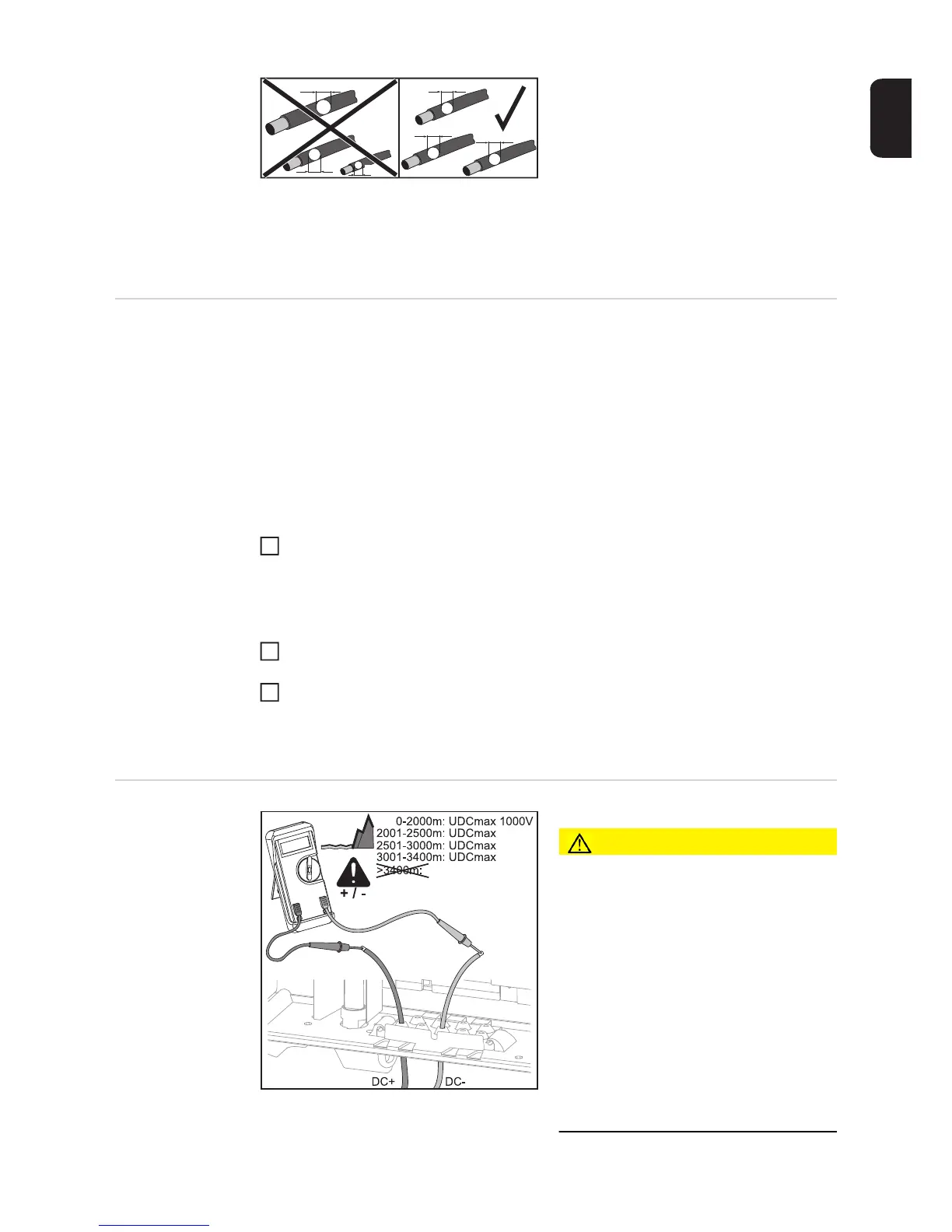

CAUTION!

Danger due to incorrect polarity and vol-

tage.

This may result in damage to the inverter.

► Check the polarity and voltage of the

solar module strings before making the

connection. The voltage must not

exceed the following values:

► when installed between 0 and 2000 m

above sea level: 1000 V

► when installed between 2001 and 2500

m above sea level: 900 V

► when installed between 2501 and 3000

m above sea level: 815 V

► when installed between 3001 and 3400

m above sea level: 750 V

D1

D2

D1

D1

D1

D3

1

2

3

900V

815V

750V

Loading...

Loading...