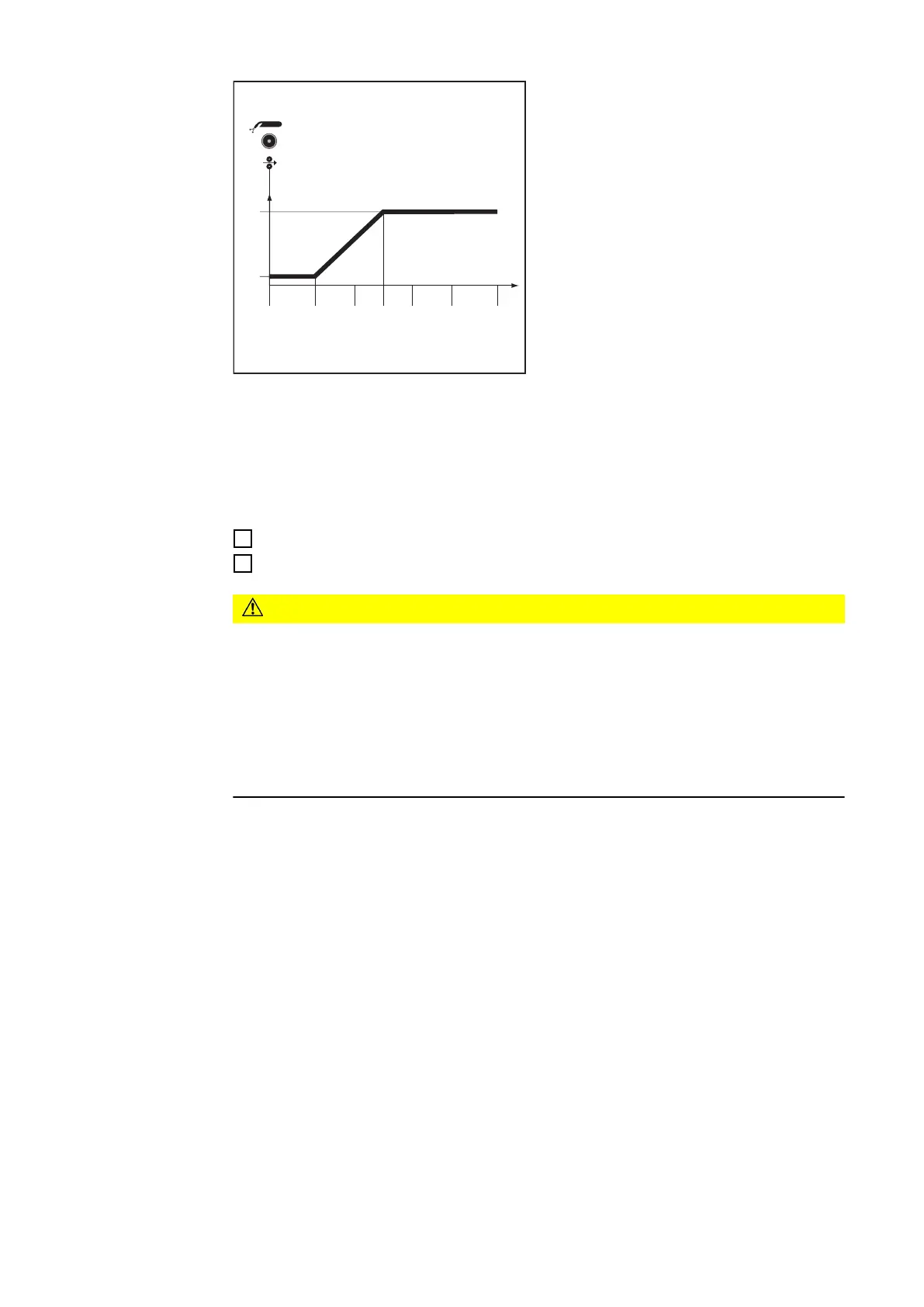

Fdi

1

23

4

5

2,5

1

t (s)

(m/min, ipm)

- Hold the button for up to one

second ... the wire speed stays at 1

m/min or 39.37 ipm for the first

second.

- Hold the button for up to 2.5

seconds ... after one second, the wire

speed increases evenly within the

next 1.5 seconds.

- Hold the button for more than 2.5

seconds ... after 2.5 seconds, the

wire is fed at a constant rate equal to

the wire speed set for the Fdi welding

parameter.

If you release the "Wire threading" button and press it again before one second has

elapsed, the sequence starts again from the beginning. This makes it possible to con-

tinuously position the wire at a low wire speed of 1 m/min or 39.37 ipm where necessary.

If there is no wire threading button present, the torch trigger can be used in a similar

way. Before using the torch trigger for wire threading, proceed as follows:

1

Press the "Mode" button to select 2-step mode

2

Set the "Ito" parameter to "Off" in the Setup menu

CAUTION!

Danger of injury and damage from electric shock and from the wire electrode

emerging from the torch.

When you press the torch trigger:

▶

Keep the welding torch away from your face and body

▶

Wear suitable protective goggles

▶

Do not point the welding torch at people

▶

Make sure that the wire electrode does not touch any conductive or grounded parts

(e.g., housing, etc.)

IMPORTANT! If the torch trigger is pressed instead of the "Wire threading" button, the

welding wire runs at the feeder creep speed (depending on the welding program) for the

first 3 seconds. After these 3 seconds, wirefeeding is briefly interrupted.

The welding system detects that the welding process should not start, but that the wire is

to be threaded in. At the same time, the gas solenoid valve closes, and the welding

voltage on the wire electrode is switched off.

If the torch trigger is kept pressed, wirefeeding restarts immediately without shielding gas

and welding voltage, and the process continues as described above.

54

Loading...

Loading...