Pulse welding

Applications Pulsed welding is welding with a pulsing welding current. It is used to weld steel pipes

out-of-position or to weld thin sheet metal.

In these applications, the welding current set at the start of welding is not always

optimum for the entire welding process:

- If the amperage is too low, the parent material will not be melted enough

- If overheating occurs, there is a danger that the liquid weld pool may drip.

Operating prin-

ciple

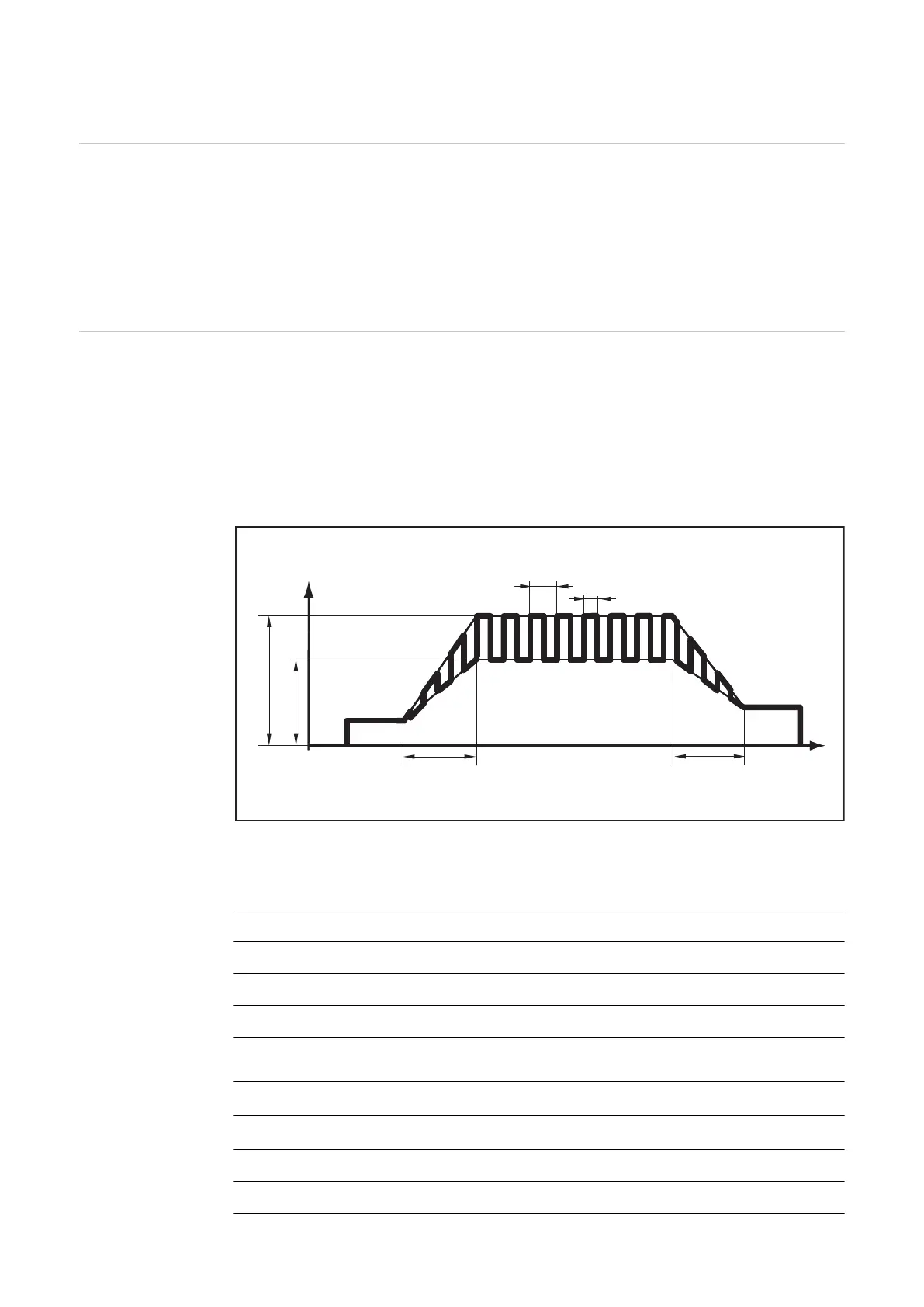

- A low base current I-G rises steeply to the significantly higher pulse current I-P and

drops back to the base current I-G after the Duty cycle dcY time.

- This results in an average current that is lower than the set pulse current I-P.

- During pulse welding, small sections of the welding location melt quickly and then

rapidly re-solidify.

The power source controls the "Duty cycle dcY" and "Base current I-G" parameters

according to the set pulse current (welding current) and pulse frequency.

1/F-P

I-P

I-G

I

t

t

up

t

down

I-S

I-E

dcY

Welding current progression curve

Adjustable parameters:

I-S Starting current

I-E Final current

F-P Pulse frequency (1/F-P = Time between two pulses)

I-P Pulse current (set welding current)

Fixed parameters:

t

up

UpSlope

t

down

DownSlope

dcY Duty cycle

I-G Base current

84

Loading...

Loading...