Section 4 Service, Configuration & Testing

23 FT742-DM (RS485) Sensors – User Manual

4 SERVICE, CONFIGURATION & TESTING

4.1 Inspection

The following checks are required to identify any signs of corrosion or damage on the sensor which may hinder

its performance. It is recommended that these checks be carried out annually.

Mechanical damage: Check the sensor body for signs of damage, paying particular attention to the seals. Also

inspect for signs of lightning damage which may appear as burns or scorch marks (or burnt smells). If damage

has occurred replace the sensor immediately. Inspect the hydrophobic cavity coating for wear, corrosion and

damage.

Corrosion; Inspect the mounting surface of the sensor and the surfaces of other mounting parts for signs of

corrosion. If corrosion is present on any surface, it should be removed using an abrasive cloth. Check that any

mechanical fixings are in good condition with no signs of corrosion and tighten as necessary. If corrosion is

present replace with parts of the appropriate finish (see Section 3).

Interconnection cable: Inspect the condition of the cable. If any part has become frayed or damaged in any

way, it should be replaced immediately. Intermittent cable faults may not be visible, but may show up as errors

in data. Confirm the intended network component values.

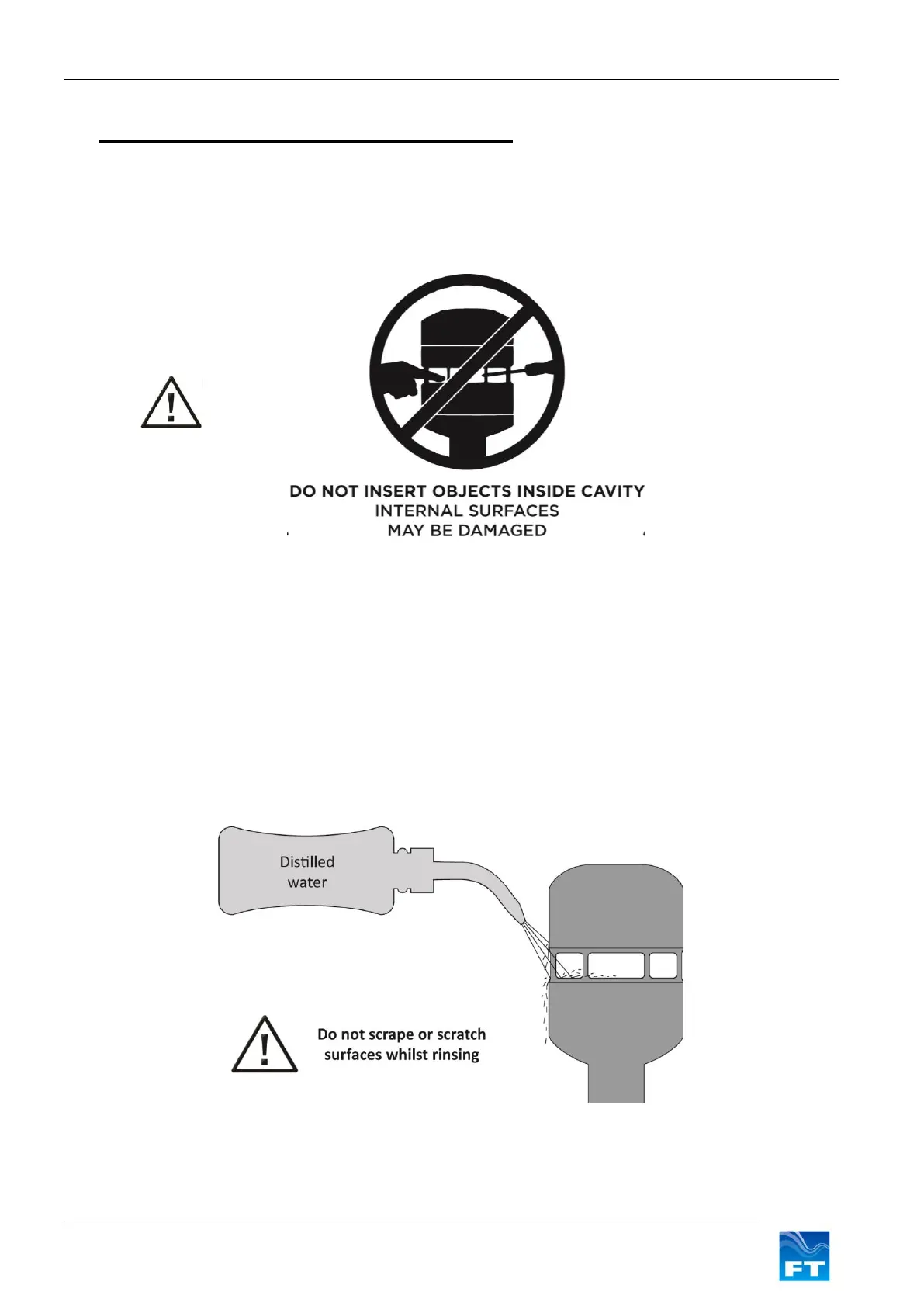

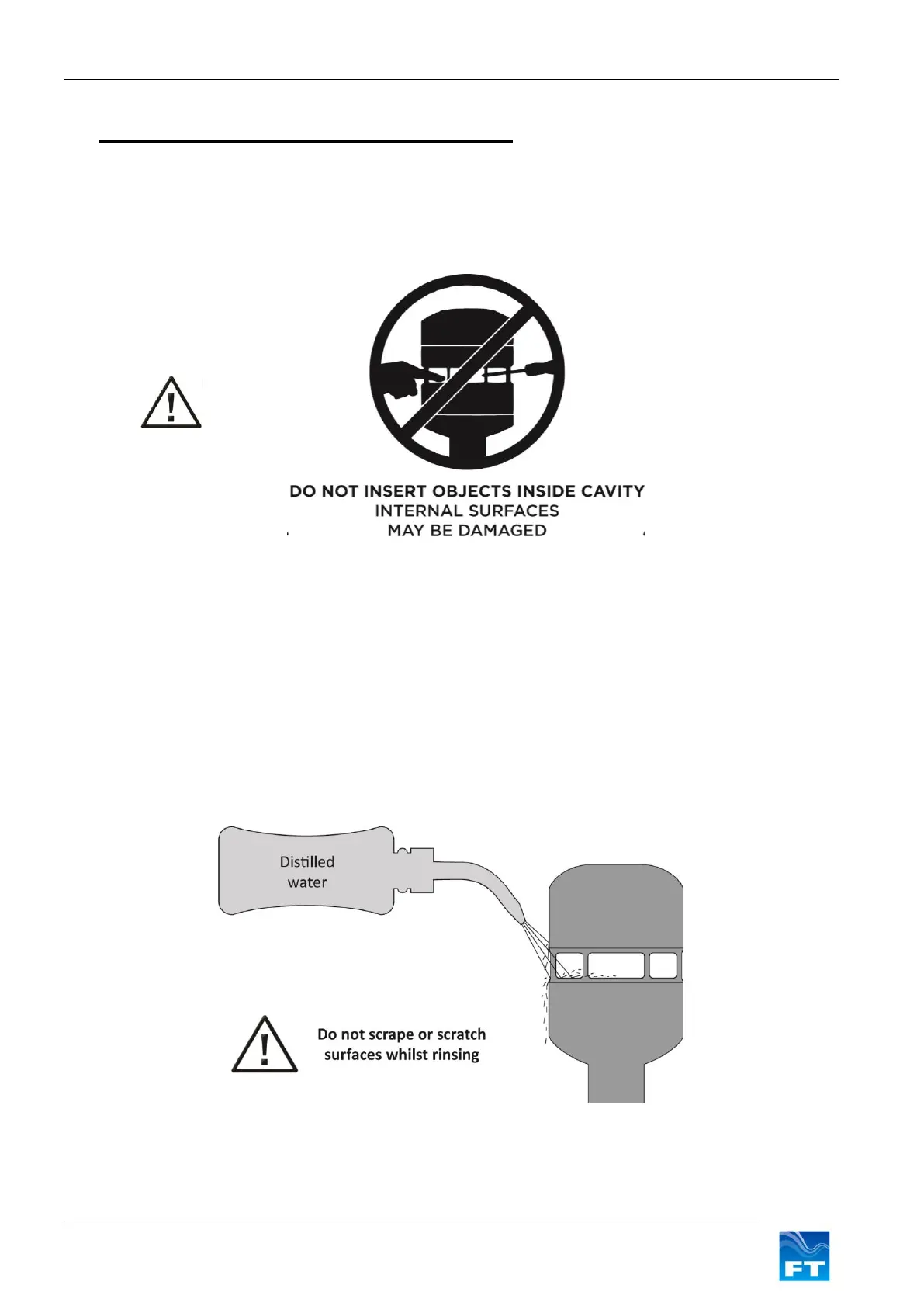

Cleaning: The measurement cavity has a special hydrophobic coating (water repelling) which helps to prevent

water building up. When water enters the measurement cavity the surface helps to wash away dust and debris

which may have settled. If any debris is present this can be removed by gently rinsing the measurement cavity

Loading...

Loading...