1

2

3

1

2

3

1

2

3,'&RQWURO

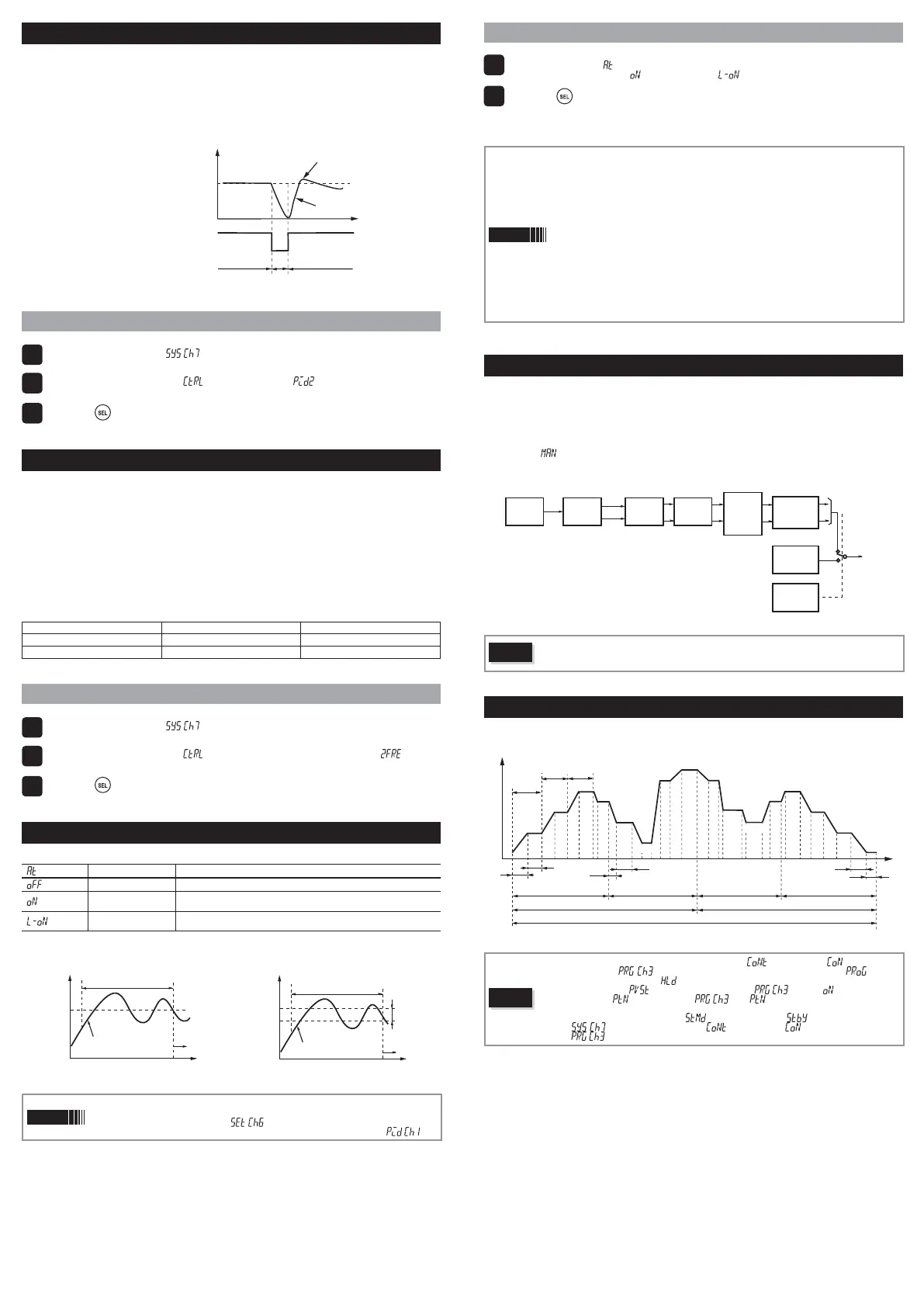

,QWKHFDVHZKLFKWKHSRZHUVXSSO\RIWKHFRQWUROWDUJHWJRHV21ĺ2))ĺ21WKLV3,'FRQWUROFDQ

suppress the amount of overshoot.

7KLVFRQWUROLQWURGXFHVDQDOJRULWKP WR SUHYHQWWKHFDOFXODWHG3,'UHVXOWIURPEHFRPLQJ D

miscalculation, even when the control loop is open.

<RXZLOOQHHGWRUXQDXWRWXQLQJWRVHWWKH3,'SDUDPHWHUZKHQXVLQJ3,'FRQWURO

Ɣ)HDWXUHVRI3,'&RQWURO

suppress overshoot

ON

OFF

control equipment power

t

SV

process value

control loop

close

close

open

PV

6HWWLQJ3,'FRQWURO

'LVSOD\WKHV\VWHPPHQX ").

'LVSOD\WKHFRQWUROSDUDPHWHU DQGFKRRVH3,' ").

Press the

key to set the value.

'HJUHHVRI)UHHGRP3,'&RQWURO

6XSSUHVVHVWKHDPRXQWRI RYHUVKRRW GXULQJ3,'FRQWURO,WXVHVWKH69 ¿OWHUZKLFKLVHIIHFWLYHLQ

reducing overshoot after a SV change or at startup.

&RQWUROODELOLW\LQGHJUHHVRIIUHHGRP3,' FRQWURO LVGLIIHUHQWGHSHQGLQJRQWKHVHWWLQJRIWKH

FRHI¿FLHQWĮDQGȕ

:KHQWKHFRHIILFLHQWĮ DQG FRHIILFLHQWȕ WKHV\VWHPSHUIRUPVWKHQRUPDO 3,'

control.

<RXFDQDGMXVWWKHFRHI¿FLHQWĮDQGȕDVIROORZV

6HWWKHFRHI¿FLHQWĮWRDQGȕWRIDFWRU\GHIDXOWVHWWLQJ

2) Perform a control to check the response (small overshoot).

,IRYHUVKRRWLVQRWUHGXFHG E\ WKLVPHDVXUHDGMXVWWKHFRHI¿FLHQWĮDQG ȕ LQDFFRUGDQFHZLWKWKH

following table.

:HUHFRPPHQG\RXWR¿[WKHFRHI¿FLHQWĮWREHFDXVHLWXVXDOO\UHTXLUHVQRDGMXVWPHQW

Control result &RHI¿FLHQWȕ FRHI¿FLHQWĮ

/DUJHRYHUVKRRW 5DLVHFRHI¿FLHQWȕE\ /RZHUFRHI¿FLHQWĮE\

Small overshoot /RZHUFRHI¿FLHQWȕE\ 5DLVHFRHI¿FLHQWĮE\

6HWWLQJGHJUHHVRIIUHHGRP3,'FRQWURO

'LVSOD\WKHV\VWHPPHQX ").

'LVSOD\WKHFRQWUROSDUDPHWHU DQGFKRRVHGHJUHHVRIIUHHGRP3,' ").

Press the

key to set the value.

7-7. Auto-tuning

5XQDXWRWXQLQJWRVHWWKH3,'SDUDPHWHUDXWRPDWLFDOO\

" " set value

Behavior Function

" "

6WRS)LQLVK 6WRSVRU¿QLVKHVDXWRWXQLQJ

"

"

1RUPDOW\SH

The standard auto-tuning for SV reference. Choose this auto-tuning in most

situations.

"

"

/RZ39W\SH

$XWRWXQLQJIRU69UHIHUHQFH&KRRVHWKLVZKHQ\RXZDQWWRVXSSUHVV

the overshoot when tuning.

PV

t

process

value

AT start

AT calculating

PID control

SV

SV-10%FS

PV

t

process

value

AT start

AT calculating

PID control

SV

Ɣ1RUPDOW\SH Ɣ/RZ39W\SH

Point

Set the following parameters before running auto-tuning.

Ɣ 39LQSXWW\SH39LQSXW XSSHU OLPLW 39LQSXWORZHUOLPLW'HFLPDOSRVLWLRQ39LQSXW

filter in the setup channel menu ("

")

Ɣ 287SURSRUWLRQF\FOH287SURSRUWLRQF\FOHLQWKH3,'FKDQQHOPHQX

").

Running auto-tuning

'LVSOD\DXWRWXQLQJ ") and choose the tuning type.

Choose the standard type (" ") or low PV type (" ") according to the control target

Press the

key to start auto-tuning.

$7ODPSSRLQWZLOOEOLQNDWWKHERWWRPRIWKHGLVSOD\GXULQJDXWRWXQLQJ

:KHQDXWRWXQLQJKDVVXFFHVVIXOO\FRPSOHWHGEOLQNLQJ$7ODPSZLOOWXUQRIIDQGRYHUZULWHVWKH

3,'

Point

Ɣ 3,'SDUDPHWHUZKLFKLVVHWDIWHUDXWRWXQLQJKDVILQLVKHGQRUPDOO\

ZLOOEHPDLQWDLQHGHYHQZKHQWKHSRZHULVWXUQHGRII+RZHYHUWKH3,'YDOXHZLOOQRWEH

changed if the power is turned off during auto- tuning. In this case, rerun auto-tuning.

Ɣ 7KHHTXLSPHQWZLOOXVH212))SRVLWLRQFRQWUROGXULQJDXWRWXQLQJVRWKHUHPD\

EHDODUJHFKDQJHLQ39DFFRUGLQJWRWKHSURFHVV'RQRWXVHDXWRWXQLQJIRUSURFHVVHV

WKDWGRQRWSHUPLWDODUJHFKDQJHLQ39'RQRWXVHDXWRWXQLQJIRUSURFHVVHVVXFKDV

pressure control and flow control that have a fast response.

Ɣ $XWRWXQLQJLVQRWEHKDYLQJQRUPDOO\LILWKDVQRWILQLVKHGDIWHUIRXURUPRUHKRXUVKDYH

SDVVHG,QWKHVHFDVHVUHFKHFNSDUDPHWHUVVXFKDVLQSXWRXWSXWZLULQJFRQWURORXWSXW

EHKDYLRUQRUPDOUHYHUVHDQGLQSXWVHQVRUW\SH

Ɣ 5HUXQDXWRWXQLQJLIWKHUHLVDODUJHFKDQJHLQ69DFKDQJHLQWKH 39LQSXWW\SHRUD

change in the control target conditions that reduces the effectiveness of the controls.

Ɣ <RXFDQUXQDXWRWXQLQJZKHQWKHFRQWUROW\SHLVVHWWRIX]]\RU3,'

Ɣ <RXFDQQRWUXQDXWRWXQLQJLQPDQXDOPRGH

Ɣ :KHQXVLQJWKH3,'VHOHFWLRQIXQFWLRQWKHDXWRWXQLQJUHVXOWIRUWKHVHOHFWHG3,'JURXS

is stored.

Ɣ $XWRWXQLQJLVIRUFLEO\WHUPLQDWHGZKHQ69FKDQJHVEHFDXVHRIWKHUDPSVRDNIXQFWLRQ

remote SV function, or ramp SV.

0DQXDO2XWSXW

$OORZVWKHFRQWURORXWSXWWREHPDQXDOO\VHWDWDQDUELWUDU\YDOXH

Ɣ0DQXDO0RGH'LVSOD\

MV indiator lights during manual mode and during parameter setting.

Ɣ6ZLWFKRYHUEHWZHHQ$XWRDQG0DQXDO

Modes can be changed by three methods: the front key (user key), communication function, or the

parameter "

".

Ɣ09RXWSXWÀRZGLDJUDP09RXWSXWSULRULW\SURFHVVLQJ

MV

MV1

MV2

MV1

MV2

MV limit

PID

calculation

output

setting

during

FALT

Soft start

limit

Specify

standby

MV output

manual

MV output

parameter

“MAN”

Dual

calculation

OFF

ON

Caution

Ɣ 09OLPLWGRHVQRWDSSO\WRWKH09RXWSXWGXULQJPDQXDORSHUDWLRQ)$/7RUVWDQGE\

7DNHH[WUDFDXWLRQZKHQ09SHUIRUPVIODVKSURWHFWLRQGXULQJFRPEXVWLRQFRQWUROE\

using the overlimit function.)

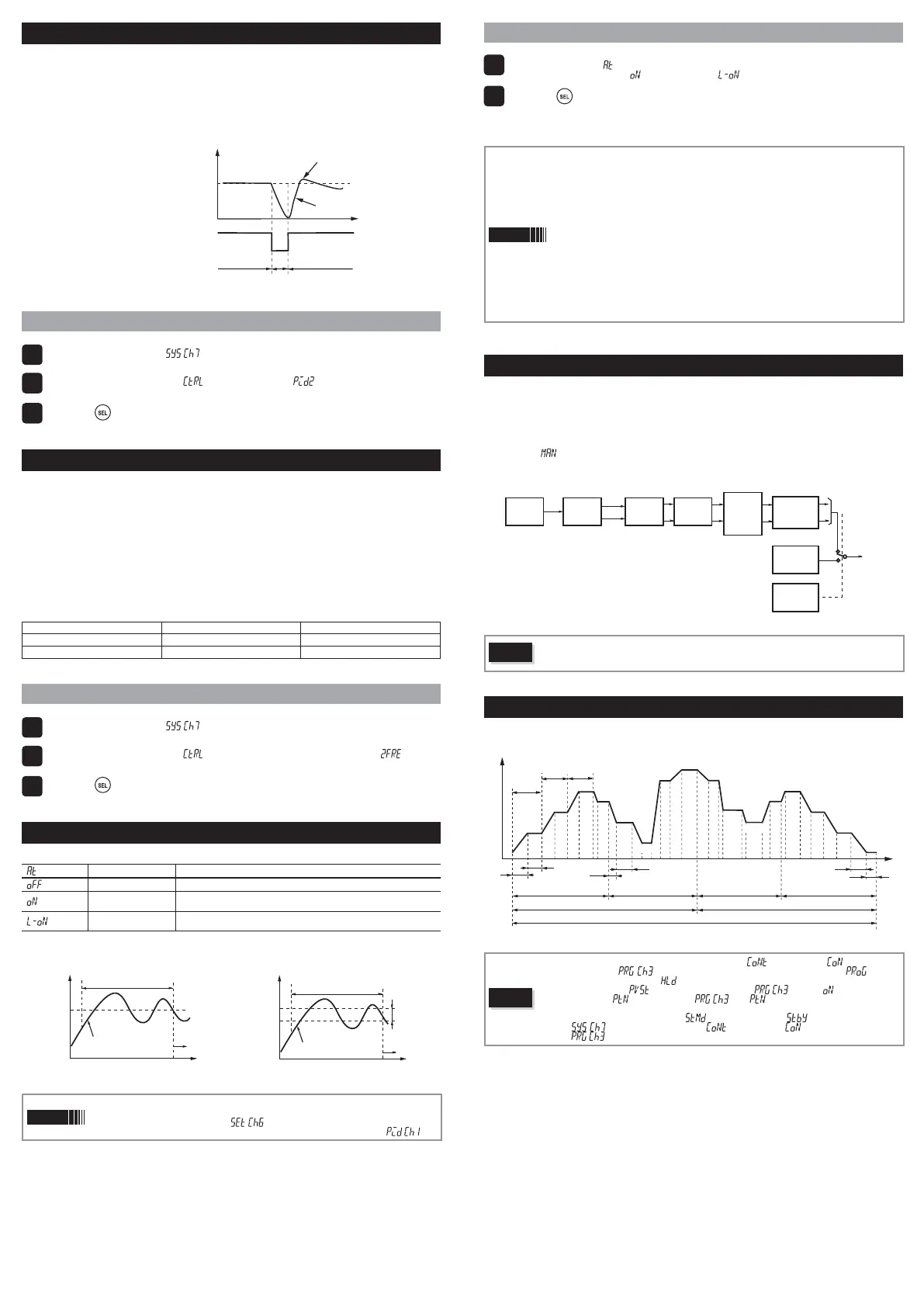

5DPS6RDN)XQFWLRQ

Automaticallyrunsaf

ter setting the times for the SV changes.

<RXFDQFKRRVHXSWRVWHSVIRUWKH69VHWWLQJDQGW\SHVRIUDPSVRDNRSHUDWLRQSDWWHUQV

SV-1

SV-2

SV-3

SV-4

SV-5

SV-7

SV-8

time

TM1r

PV

TM1s

TM5r

TM5s

TM16r

TM16s

VWHSWRSDWWHUQ

SV-9

69

SV-12

SV-13

SV-14

SV-15

SV-16

SV-11

SV-6

VWHSWRSDWWHUQ

VWHSWRSDWWHUQ

VWHSWRSDWWHUQ

VWHSWRSDWWHUQ

VWHSWRSDWWHUQ

VWHSWRSDWWHUQ

SV

step1

step2

step3

Caution

Ɣ :KHQ XVLQJWKHV\VWHPLQWKHUHVWRUHPRGH FRQWLQXH LQWKHUDPS

soak menu ("

GRQRWVHWWKHUDPSVRDNFRQWUROFRPPDQG ") of the

operation menu to hold ("

") during the ramp period at the beginning of the pattern.

Ɣ :KHQ39VWDUW

RIWKHUDPSVRDNPHQX ") is on (" "), set the pattern

parameter ("

RIUDPSVRDN ") to " VHWWLQJWKDWVWDUWVZLWK

seg ramp).

Ɣ 'RQRWVHWWKH6WDUWXSPRGH

VWDQGE\PRGH ") of the sys- tem menu

("

") and the restore mode (" FRQWLQXH RIWKHUDPSVRDNPHQX

("

") at the same time.

- 15 -

Loading...

Loading...