13-9-666 Page 18

DISCHARGE SERVICE LINE - The discharge service line connection on both water-cooled and air-

cooled units is made at the right hand corner of the unit, viewed from the opposite end from control panel

side. When connecting two or more GD rotary screw units on a common manifold, each unit is isolated

by the check valve in the unit discharge line. If a Gardner Denver rotary screw unit is connected to

another compressor on a common manifold be sure the other compressor has a check valve in the line

between the machine and the manifold. If a rotary screw and a reciprocating compressor are connected

together on a common manifold, an air receiver must be located between the two units.

Discharge air used for breathing will cause severe injury or death.

Consult filtration specialists for additional filtration and treatment equipment to

meet health and safety standards.

BLOWDOWN VALVE PIPING - The blowdown valve is piped back into the airend between the inlet valve

and air filter.

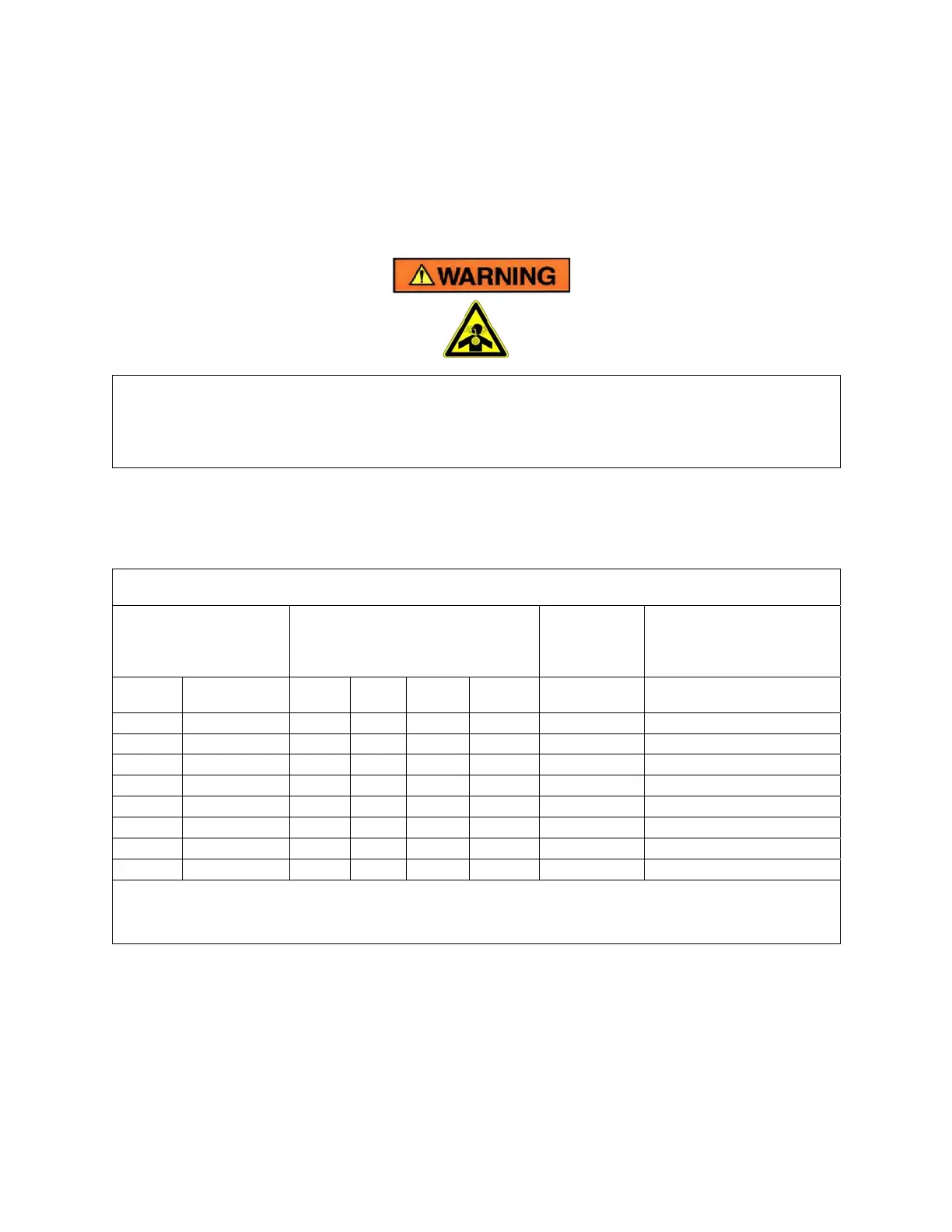

HEAT EXCHANGER

Water Temperature to Heat

Exchanger

(gpm)

Maximum

Water Flow

(gpm) **

Approximate Water

Pressure Drop @ 90° F

Water Temperature

(psi)

HP Model

60° F 70° F 80° F 90° F

125 HP EAQ99Q 12.1 15.2 20.2 30.3 40.0 4.0

125 HP EBQ99M 11.3 14.1 18.9 28.3 40.0 4.0

150 HP EAQ99Q 14.6 18.2 24.3 36.4 40.0 4.0

150 HP EBQ99M 13.1 16.3 21.8 32.7 40.0 4.5

200 HP EAQ99Q 18.3 22.8 30.4 45.5 110.0 5.0

200 HP EAU99Q 18.9 23.6 31.5 47.3 110.0 5.0

200 HP EBU99C 18.9 23.6 31.5 47.3 110.0 5.0

200 HP EBQ99M 16.4 20.4 27.3 40.9 110.0 5.0

* 80° F Maximum Water Temperature when aftercooler & oil cooler are piped in series (std).

** Flows exceeding "Maximum Water Flow" will cause severe erosion and will void unit warranty.

Loading...

Loading...