6.5 PID Control

6.5.1 Speed PID Control

H-40 Configuration Mode

H-41 Motor Control Principle

U/f Advanced Vector Control Flux Sensorless Flux w/ enc. feedb

[0] Speed open-loop Not Active Not Active ACTIVE N.A.

[1] Speed closed-loop N.A. ACTIVE N.A. ACTIVE

[2] Torque N.A. N.A. N.A. Not Active

[3] Process Not Active ACTIVE ACTIVE

Table 6.15 Control Configurations where the Speed Control is active

“N.A.” means that the specific mode is not available at all. “Not

Active” means that the specific mode is available but the Speed

Control is not active in that mode.

NOTE!

The speed control PID will work under the default

parameter setting, but tuning the parameters is highly

recommended in order to optimize motor control

performance. The two flux motor control principles are

particularly dependant on proper tuning to yield their full

potential.

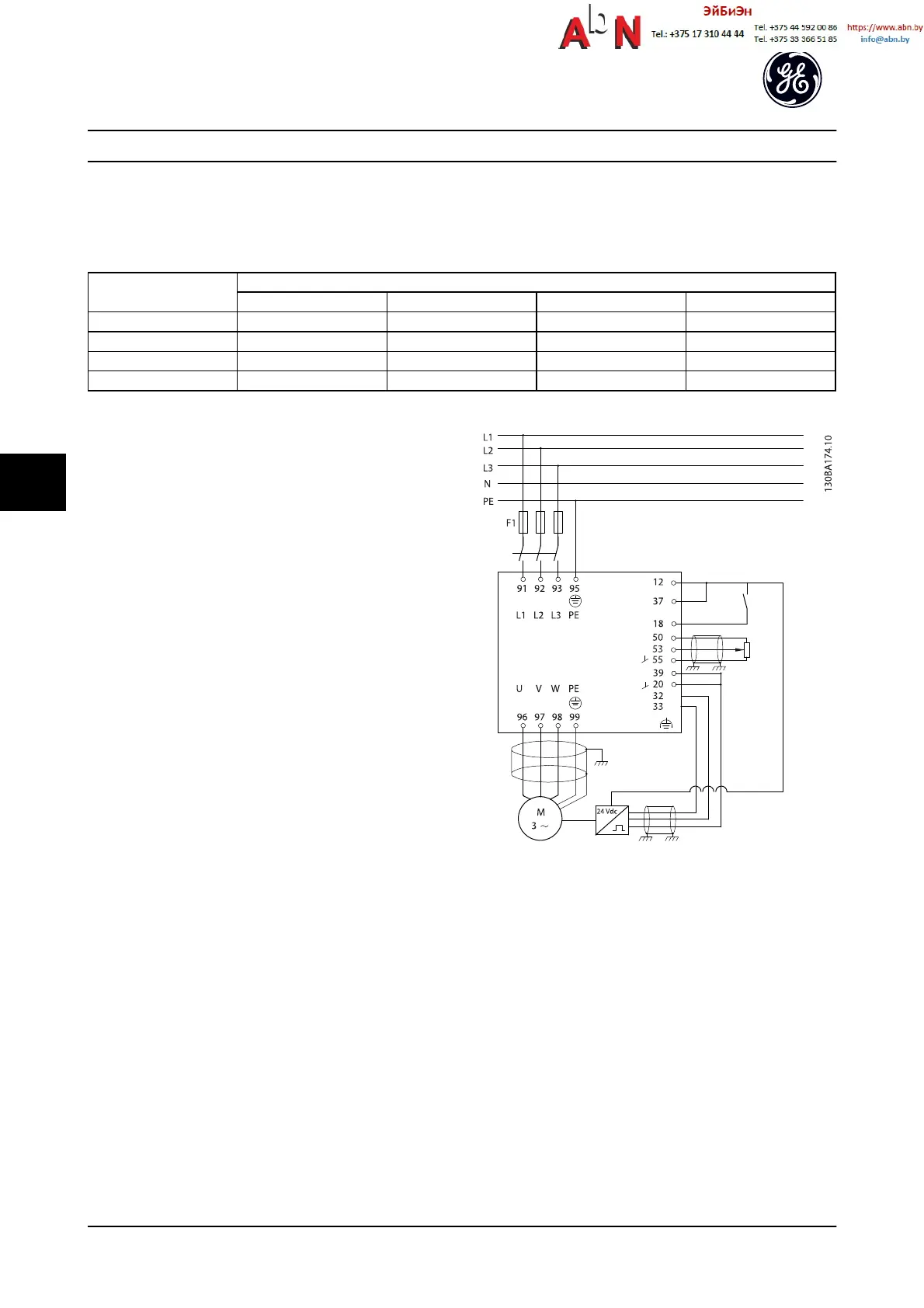

Example of how to Program the Speed Control

In this case, speed PID control is used to maintain a

constant motor speed regardless of the changing load on

the motor. The required motor speed is set via a potenti-

ometer connected to terminal 53. The speed range is 0 to

1,500 RPM corresponding to 0 to 10 V over the potenti-

ometer. Starting and stopping is controlled by a switch

connected to terminal 18. The Speed PID monitors the

actual RPM of the motor by using a 24 V (HTL) incremental

encoder as feedback. The feedback sensor is an encoder

(1024 pulses per revolution) connected to terminals 32 and

33.

Figure 6.17

Application Setup Examples

AF-650 GP

TM

Design and Installation Guide

6-14 DET-767A

6

Loading...

Loading...