Evolution Series E9000 User Manual

11

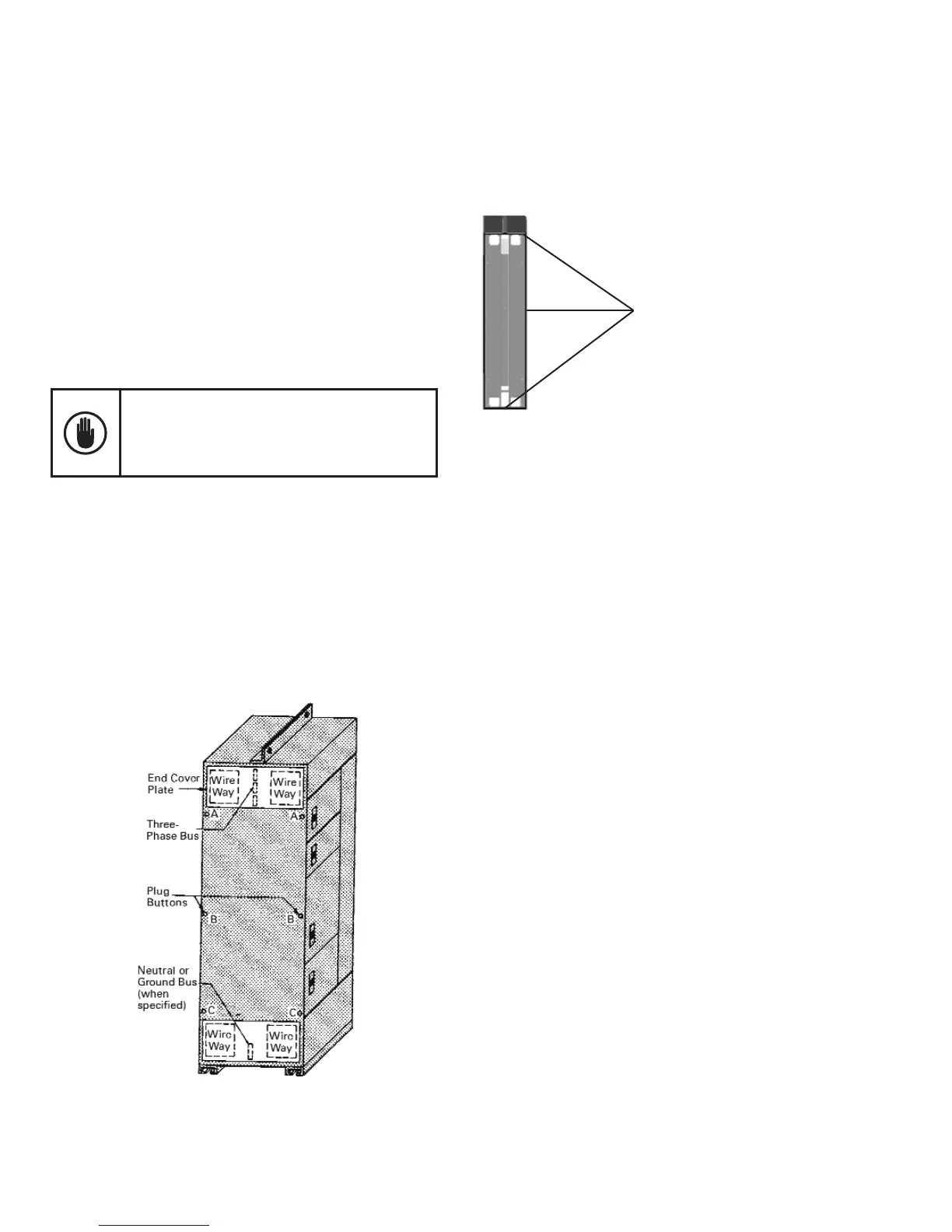

Positioning and Joining Sections

If groups of sections are to be joined together in a nal

lineup, remove the end cover plates and the plug buttons,

from the sides of the sections to be joined. Figure 10

shows the side views, with the end cover plates removed,

for 20-inch-deep sections with 2-inch (50.8 mm) and

4-inch (101.6 mm) bus bars.

Carefully check and remove dirt, dust or bits of packing

material from the interior of all sections. Use a brush,

soft cloth or vacuum cleaner.

Do not use compressed air to clean the equipment

if it contains moisture. Remove all hardware

packages, drawings and other items shipped with

the equipment. Check all nuts, bolts, and electrical

joints for tightness.

All cables entering the bottoms of sections should be

pulled through conduits to a point where they will be

accessible after the equipment is in place. Sections can

be moved to their nal position and properly leveled.

For Arc Resistant plenum-less design, the cables can

enter either through the front or rear aluminum ap on

top of the section.

Figure 10. Side view of a 20-inch-deep section showing the cover

plates, plug bottoms and joining points

For Type 12 and Arc Resistant enclosure, see Figure

10A for proper gasket in between the section splits. For

additional gasket material order part number 245A1888P5.

Gaskets

Figure 10A. Type 12 and Arc Resistant

gasket material between section splits

NEC Work Space

NEC Work Space is dened in Table 110.26(a) Working

Spaces. Included in these clearance requirements is the

step-back distance from the face of the equipment.

Table 110.26(a) provides requirements for clearances

away from the equipment, based on the circuit voltage

to ground, and whether there are grounded or unground-

ed objects in the step-back space, or if there are exposed

live parts across from each other. The voltages to ground

consist of two groups: 0 to 150 and 151 to 600, inclusive.

Remember, where an ungrounded system is utilized, the

voltage to ground will be the greatest voltage between

the given conductor and any other conductor of the

circuit. For example, the voltage to ground for a 480-volt

ungrounded delta system is 480 volts.

See Figure 14 for general working clearance requirements.

Distances are measured from the live parts if the live

parts are exposed, or from the enclosure front if live

parts are enclosed. If any assemblies, such as switch-

boards or motor control centers, are accessible from the

back and expose live parts, the working clearance

dimensions would be required at the rear of the equipment,

as illustrated. Note that for Condition 3, where there is

an enclosure on opposite sides of the working space,

the clearance for only one working space is required.

Loading...

Loading...