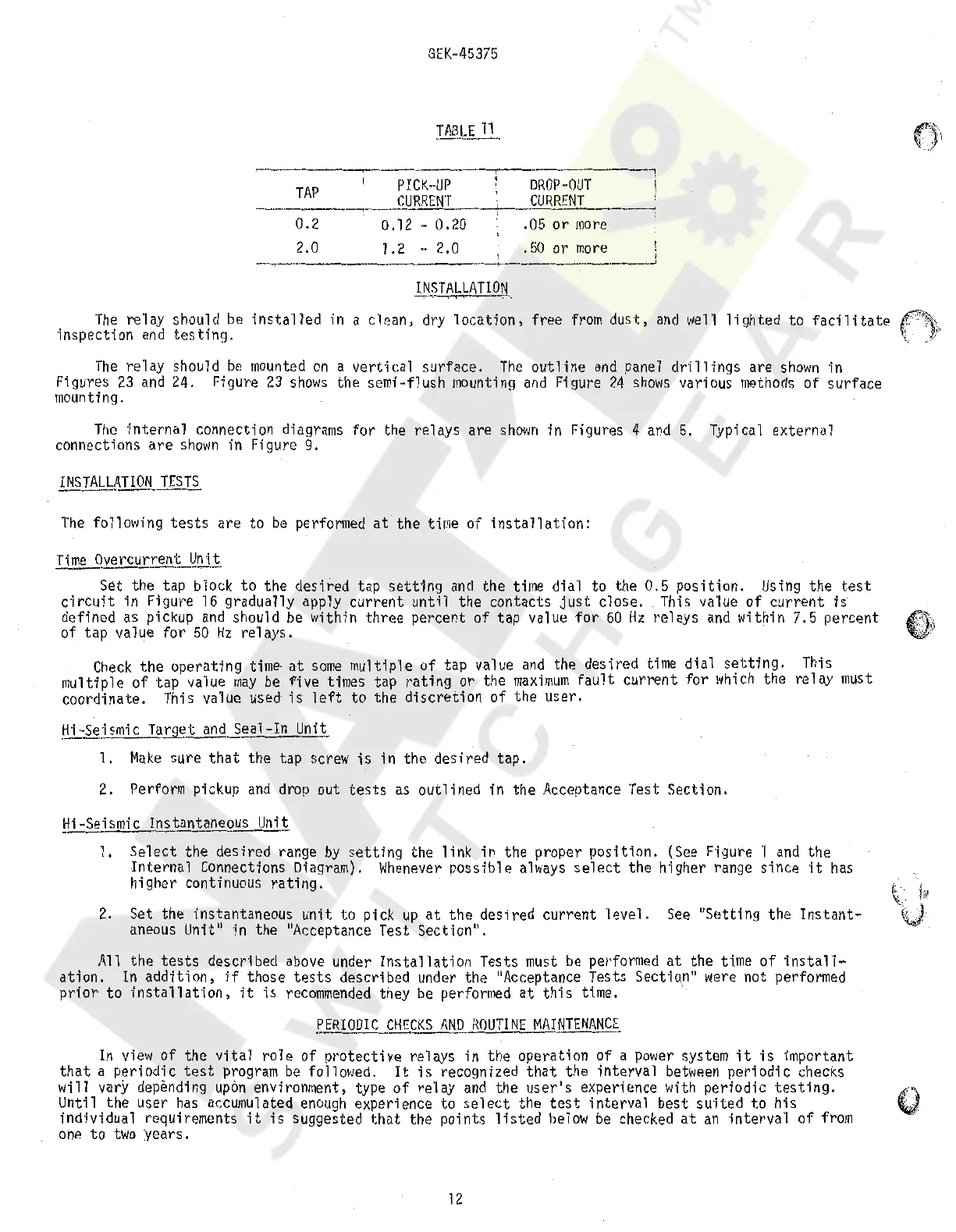

TAP

0.2

GEK-45375

PICK-UP

CURRENT

0.12 - 0.20

DROP-OUT

CURRENT

.05

or

more

2.0 1.2 - 2.0 .50 or

more

I I

--.

-··-------------~

~

INSTALLATION

The

relay should

be

installed

in a clean, dry

location,

free

from

dust,

and

>Jell

lighted

to

facilitate

inspection

and

testing.

The

relay should

be

mounted

on

a

vertical

surface.

The

outline

and

panel

drillfogs

are

shown

in

Figures

23

and

24. Figure

23

shows

the semi-flush mounting

and

Figure

24

shows

various

methods

of

surface

mounting.

The

internal

connection

di

a

grams

for the relays are

shown

in Figures 4

and

5. Typical external

connections

are

shown

in Figure 9.

The

following

tests

are to

be

performed

at

the time of

installation:

Time

Overcurrent Unit

Set the tap block to the desired tap

setting

and

the time dial to the 0.5

position.

Using

the

test

circuit

in Figure

16

gradually apply

current

until the contacts

just

close. This value

of

current

is

defined

as

pickup

and

should

be

within three percent of tap value for

60

Hz

relays

and

within 7.5 percent

of tap value for

50

Hz

relays.

Check

the operating

time·

at

some

multiple of tap value

and

the desired time dial

setting.

multiple of tap value

may

be

five times tap

rating

or the

maximum

fault

current

for

which

the

coordinate. This value used

is

left

to the

discretion

of

the user.

Hi-Se_ismic

Target

and

Seal-In Unit

1.

Make

sure

that

the tap

screw

is

in the desired tap.

2.

Perform pickup

and

drop out

tests

as

outlined in the Acceptance Test Section.

~i-Seismic

Instantaneous

Uni~

This

relay

must

l.

Select the desired range

by

setting

the

link

in the proper posit·ion.

{See

F·igure

·1

and

the

Internal Connections Diagram).

Whenever

possible

always

select

the higher range since ·it

has

higher continuous

rating.

2.

Set the instantaneous unit to pick

up

at

the desired current 'level.

See

"Setting the

Instant-

aneous

Unit" in the "Acceptance Test Section".

All

the

tests

described

above

under

Installation

Tests

must

be

performed

at

the time of

install~

ation.

In

addition,

if

those

tests

described under the "Acceptance Tests Sect'lo.n"

were

not performed

prior

to

installatfon,

it

is

recommended

they

be

performed

at

this

time.

f_ERIODJC

CHE~KS

AND

ROUTINE

MAINTENANCE_

In

view

of the

vital

role

of protective relays in the operation of a

power

system

it

is

important

that

a periodic

test

program

be

followed.

It

is

recognized

that

the interval

between

periodic checks

will vary depending

upon

environment, type

of

re'lay

and

the

user's

experience with periodic

testing.

Until the user

has

accumulated

enough

experience to

select

the

test

interval best

suited

to his

individual requirements

it

is

suggested

that

the points

listed

below

be

checked

at

an

interva'I of

from

one

to

two

:years.

12

IP':!.,;

~-

j''

11"1

v

Courtesy of NationalSwitchgear.com

Loading...

Loading...