GEK-45375

With

•he tap block

set

for the lowest tap

and

the time dial

set

where

contacts are

just

open,

adjust

tk~

control spring to

just

close the contacts within the

limits

given

below

which

are plus

and

minus

1%

of the tap

amps,

See

Table 12.

o"

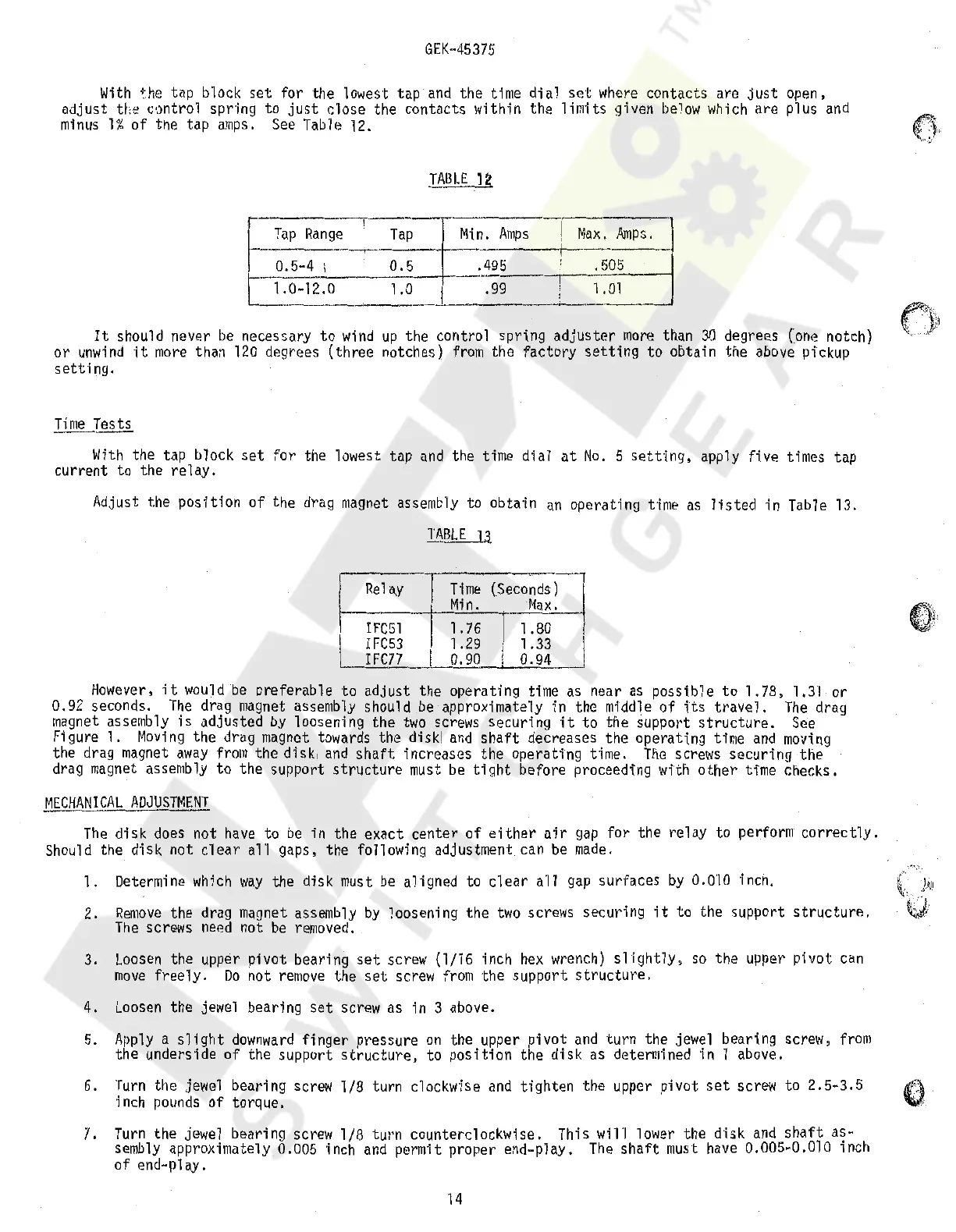

TABLE

12

§

P

Rang_:_~_Ta_p_-1-_M_i,n.

Amps

-~.

Amps

.

. 5-4

i 0. 5 .495 .

505

--r-·

0-12.0 1.0 .99

1.01

·---~

------------'

It

should never

be

necessary to

wind

up

the control spring

adjuster

more

th.an

30

degrees (one notch)

or

unwind

it

more

than

120

degrees (three notches)

from

the factory

setting

to obtain the

above

pickup

setting.

Time

Tests

With

the tap block

set

for

the lowest tap

and

the time dial

at

No.

5 sett·ing, apply

five

times tap

current to the

relay.

Adjust the position of the drag

magnet

assembly to obta'in

an

operating time

as

listed

in Table 13.

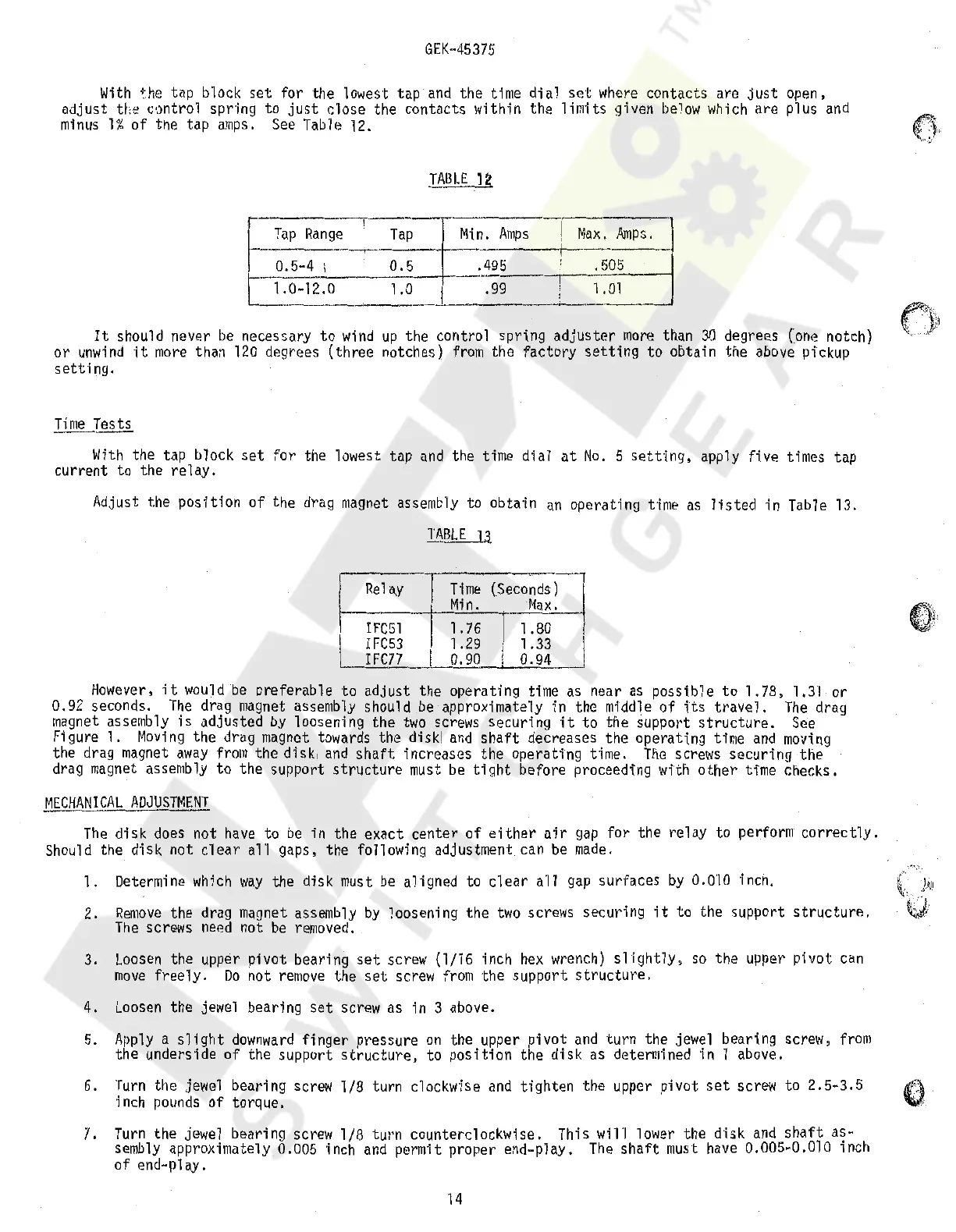

Relay

Time

(Seconds)

Min.

Max.

lT

l

~

IFC51

1.80

IFC53

l •

29

I

l.u

!FC77

I

0.90 i 0.94

However,

it

would

be

preferable to adjust the operating time

as

near

as

possible to 1.78,

1.31

or

0.92 seconds.

The

drag

magnet

assembly should

be

approximately in the middle

of

its

travel.

The

drag

magnet

assembly

is

adjusted

by

loosening the

two

screws securing

it

to the support

structure.

See

Figure 1.

Moving

the drag

magnet

towards the disk!

and

shaft

decreases the operating time

and

moving

the drag

magnet

away

from

the disk,

and

shaft

increases the operating time.

The

screws securing the

drag

magnet

assembly to the support

structure

must

be

tight

before proceeding with

other

tfme

checks.

Jl1ECHANICAL

ADJUSTMENT

The

disk

does

not

have

to

be

in the exact center

of

either

air

gap

for the relay to perform

correctly.

Should

the disk not

clear

all

gaps, the following adjustment can

be

made.

1 ,

Oetermi

ne

which

way

the disk

must

be

a 1 i

gned

to cl

ear

a

11

gap

surfaces

by

0.

O'\O

·inch.

(.

,i,

11

,

2.

Remove

the drag

magnet

assembly

by

loosening the

two

screws securing

it

to the support

structure.

V

The

screws

need

not

be

removed.

3.

Loosen

the upper pivot bearing

set

screw

(l/16

inch

hex

wrench)

slightly,

so

the upper pivot

can

move

freely.

Do

not

remove

the

set

screw

from

the support

structure.

4.

Loosen

the jewel bearing

set

screw

as

in 3 above.

5.

Apply

a

slight

downward

finger pressure

on

the upper pivot

and

turn the jewel bearing screw,

from

the underside of the support

structure,

to

position

the disk

as

determined in l above.

6.

Turn

the jewel bearing screw 1/8 turn clockwise

and

tighten the upper pivot

set

screw to 2.5-3.5

'inch

pounds

of torque.

7.

Turn

the jewel bearing screw 1/8 turn counterclockwise, This

wil'J

lower the disk

and

shaft

as-

sembly

approximately 0.005 inch

and

permit proper end-play,

The

shaft

must

have

0.005-0.010 inch

of end-play.

14

11'1'.'i

~

.

Courtesy of NationalSwitchgear.com

Loading...

Loading...