– 56 –

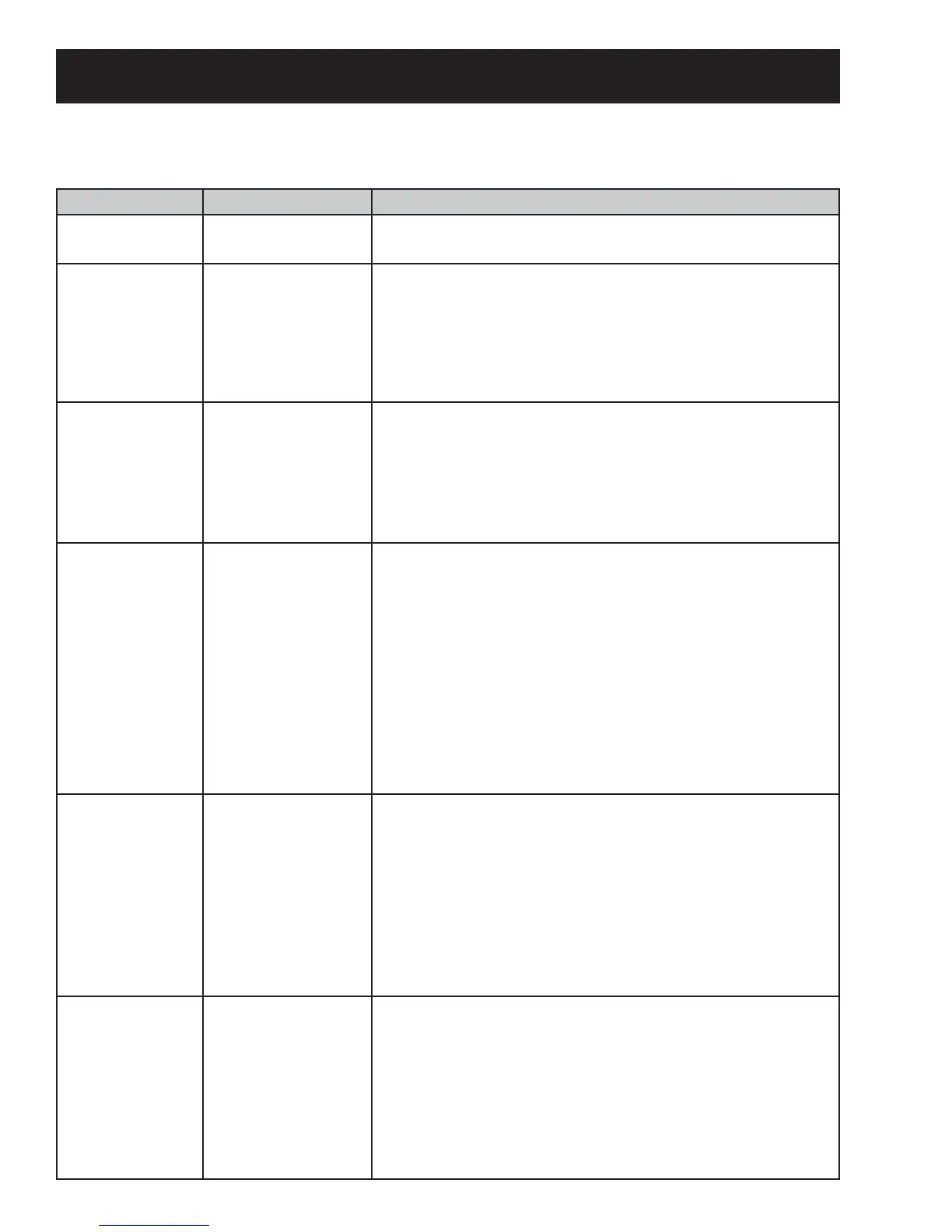

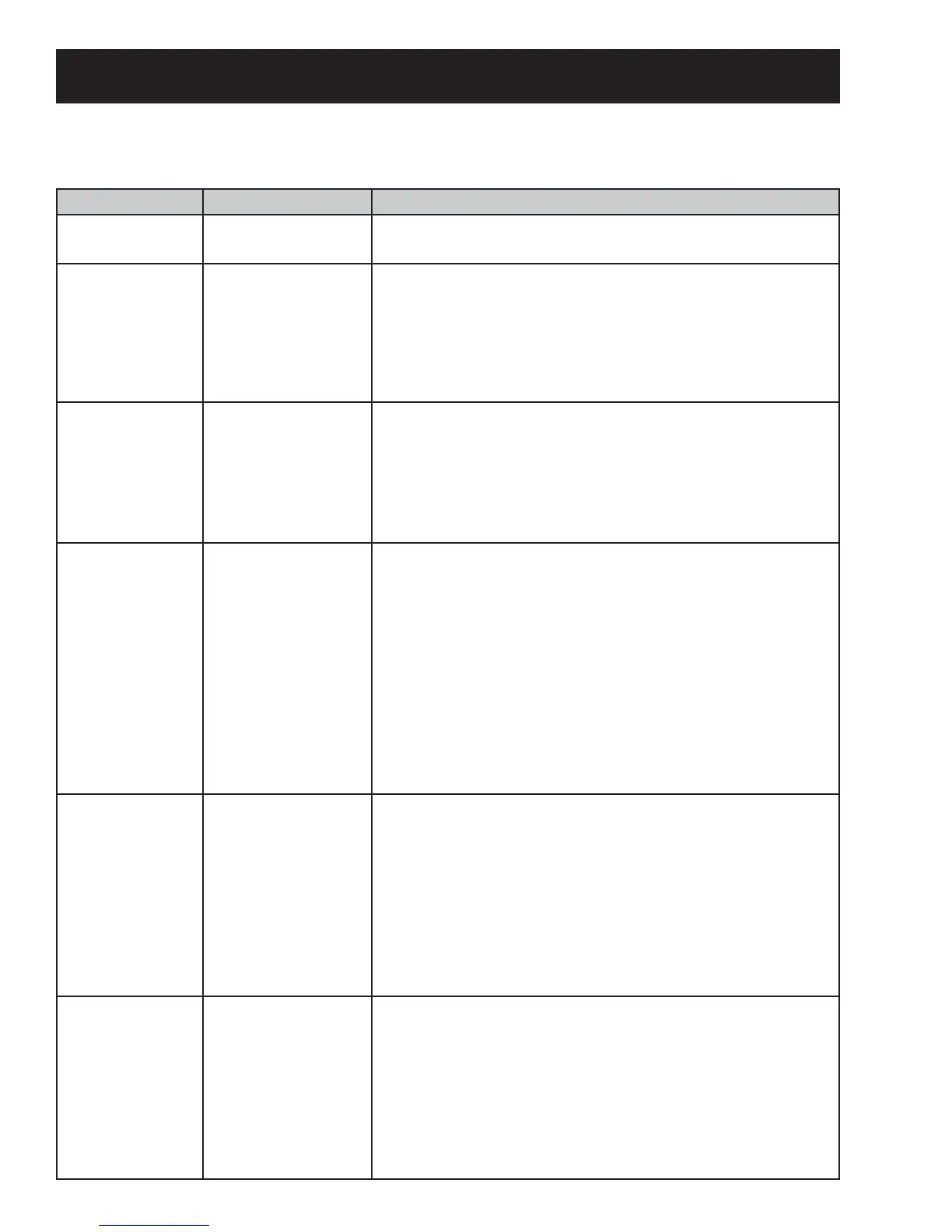

Error Codes

(Continued Next Page)

Error Code Description Action

E1 UI EEPROM

E2 Power EEPROM

Internal problem with

UI or MC board

Replace board as necessary.•

E4 Thermistor

Short

E5 Thermistor

Open

Water Temperature

Sensor Problem

Check integrity of wiring and connections between main •

control and Thermistor Assembly.

Using ohmmeter, measure Thermistor resistance. If outside •

expected range, replace Thermistor Assembly.

IF ABOVE STEPS DO NOT CLEAR THE PROBLEM:

Replace the main control.•

E6 Pressure

Switch

Water Level Sensor

Problem

Check integrity of wiring and connections between main •

control and Water Level Sensor.

Check integrity of Water Level Sensor; replace if necessary.•

Check drain system.•

IF ABOVE STEPS DO NOT CLEAR THE PROBLEM:

Replace the main control.•

E7 Slow Fill Fill Problem Ensure manual water valves are fully open.•

Check if water strainers on solenoid valve assembly are •

clogged.

Check for obstructions inside inlet water hoses.•

Ensure solenoid valves do not leak when the valves are de-•

energized and the washer is powered down.

Measure coil resistance for both valves. If outside range •

(1000–1250 ohms at room temp.), replace solenoid valve

assembly.

IF ABOVE STEPS DO NOT CLEAR THE PROBLEM:

Replace solenoid valve assembly.•

E8 Drain System Drain Problem Ensure pump strainer is clean and free of debris.•

Check for obstruction inside the drain hose.•

Check pump impeller blades and bearing; if evidence of •

blade damage or seized bearings are present, replace the

pump.

Check the electrical connections at the pump motor and •

harness.

Measure pump motor resistance. If outside range (9–14 •

ohms at room temp.), replace the pump.

E9 Dispenser

Motor

Dispenser Problem Check for obstruction in dispenser mechanism and •

linkages.

Check the electrical connections at the motor feedback •

switch and in the harness.

Check the electrical connections of water valves in the •

harness.

IF ABOVE STEPS DO NOT CLEAR THE PROBLEM:

Replace dispenser motor assembly.•

NOTE: It’s important to note error codes should only be used to help identify components which require

testing. Never replace a part based solely on an error code. The control can generate a false error if the

right conditions exist. Use the code only as a reference and always check the component before replacing.

Loading...

Loading...