5.4 Mounting and Installation Procedure

Observe the following guidelines to properly mount and install the QuickPanel

+

Operator Interface:

Note To order replacement gaskets, refer to the part number listed in Appendix B.

• The enclosure should be of metal material.

• The metal enclosure panel should ensure proper thickness and rigidity suitable to minimize impact to the QuickPanel

+

unit.

• The recommended torque for the plastic back cover and interior metal cover for the 10, 12, and 15” QuickPanel

+

display units that is accessed for panel updates and serial port DIP Switches is 0.5 Nm (4.4 in-lb).

• To avoid gasket degradation, limit repeated insertions or removals of the unit and retightening of the mounting

clips. For full protection, always use a fresh gasket.

• The unit will not fit through the cutout with any cables connected, or with the power supply plug inserted in the

socket.

Caution

When installing the QuickPanel

+

into the panel, pay careful attention while

handling the unit so it does not drop and damage the unit.

➢ To install the QuickPanel

+

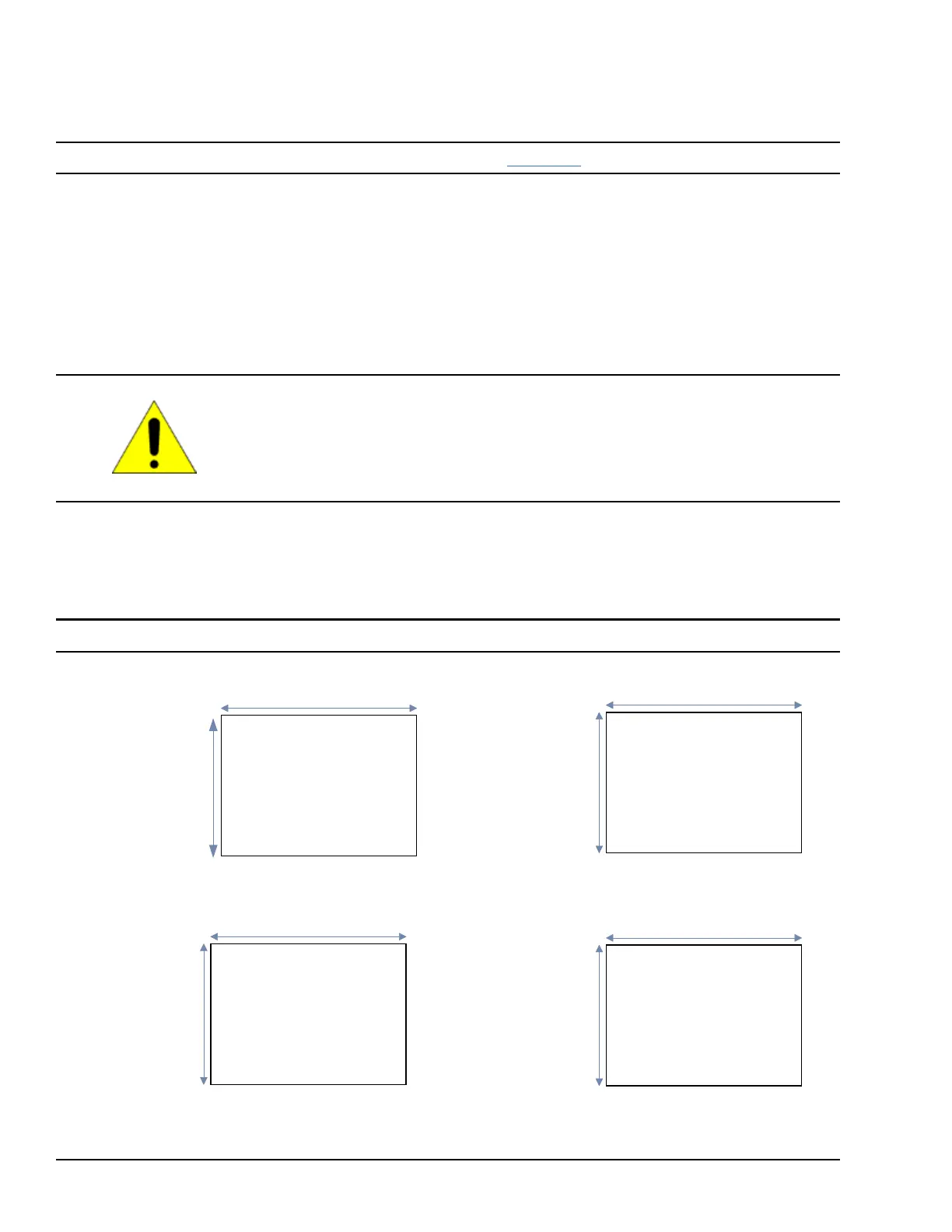

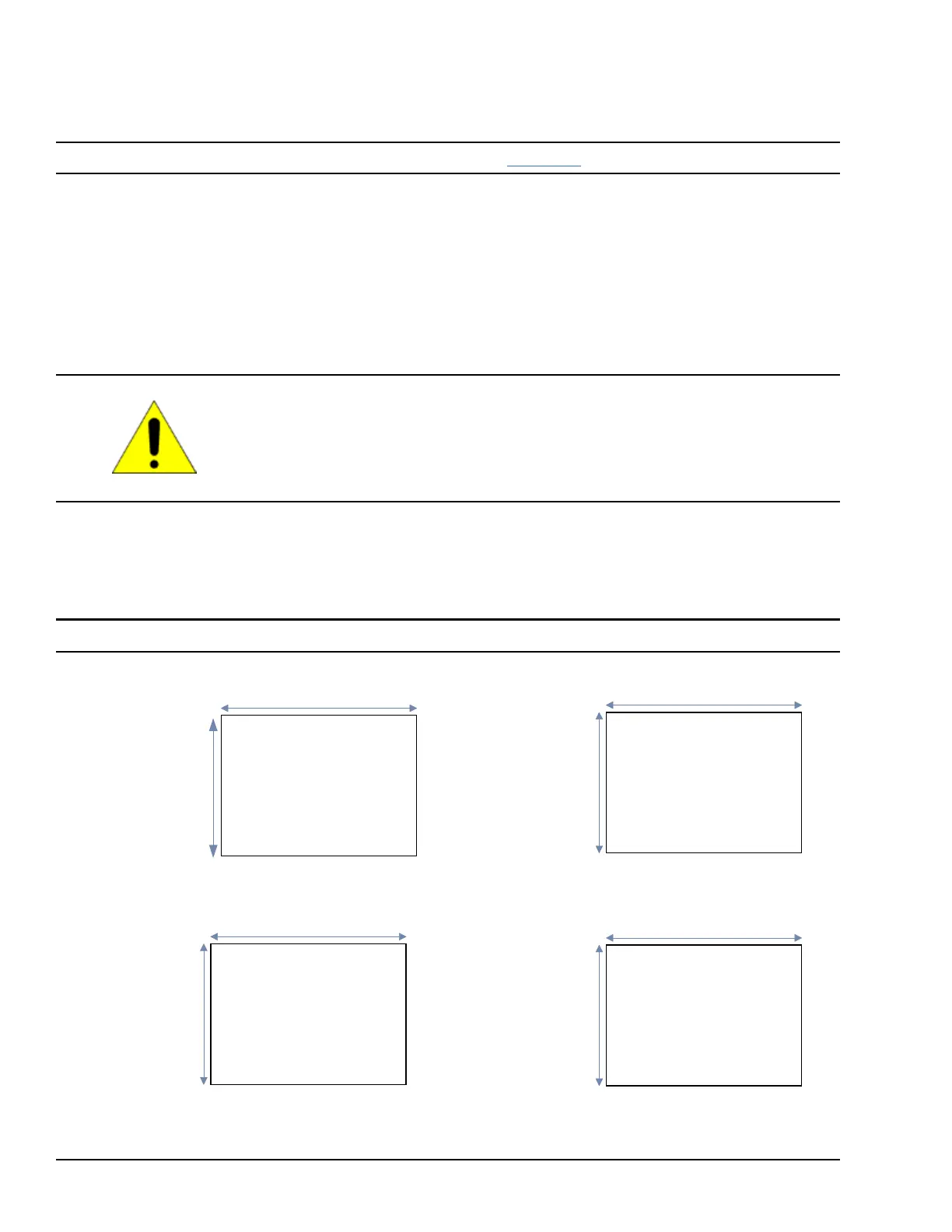

1. Cut an opening in the panel according to the specifications in the following figures.

Note Panel cutout tolerances are +0.50, –0.00 mm (+0.02, –0.00 in).

183.50 mm (7.22 in)

266 mm (10.47 in)

Panel T

hickness

:

1.0 to 5.0

mm

(0.04 to 0.20 in)

Panel T

hickness

:

1.6 to 5.0

mm

(0.06 to 0.20 in)

IC755CxSO6RDx or

IC755CxW07CDx

Panel Cutout

Dimensions

IC755CxS10CDx Panel Cutout Dimensions

302 mm

(

11.89 in)

379 mm (14.92 in)

Panel T

hickness

:

1.6 to 5.0

mm

(0.06 to 0.20 in)

Panel T

hickness

:

1.6 to 5.0

mm

(0.06 to 0.20 in)

IC755CxS12CDx Panel Cutout Dimensions

IC755CxS15CDx Panel Cutout Dimensions

Loading...

Loading...