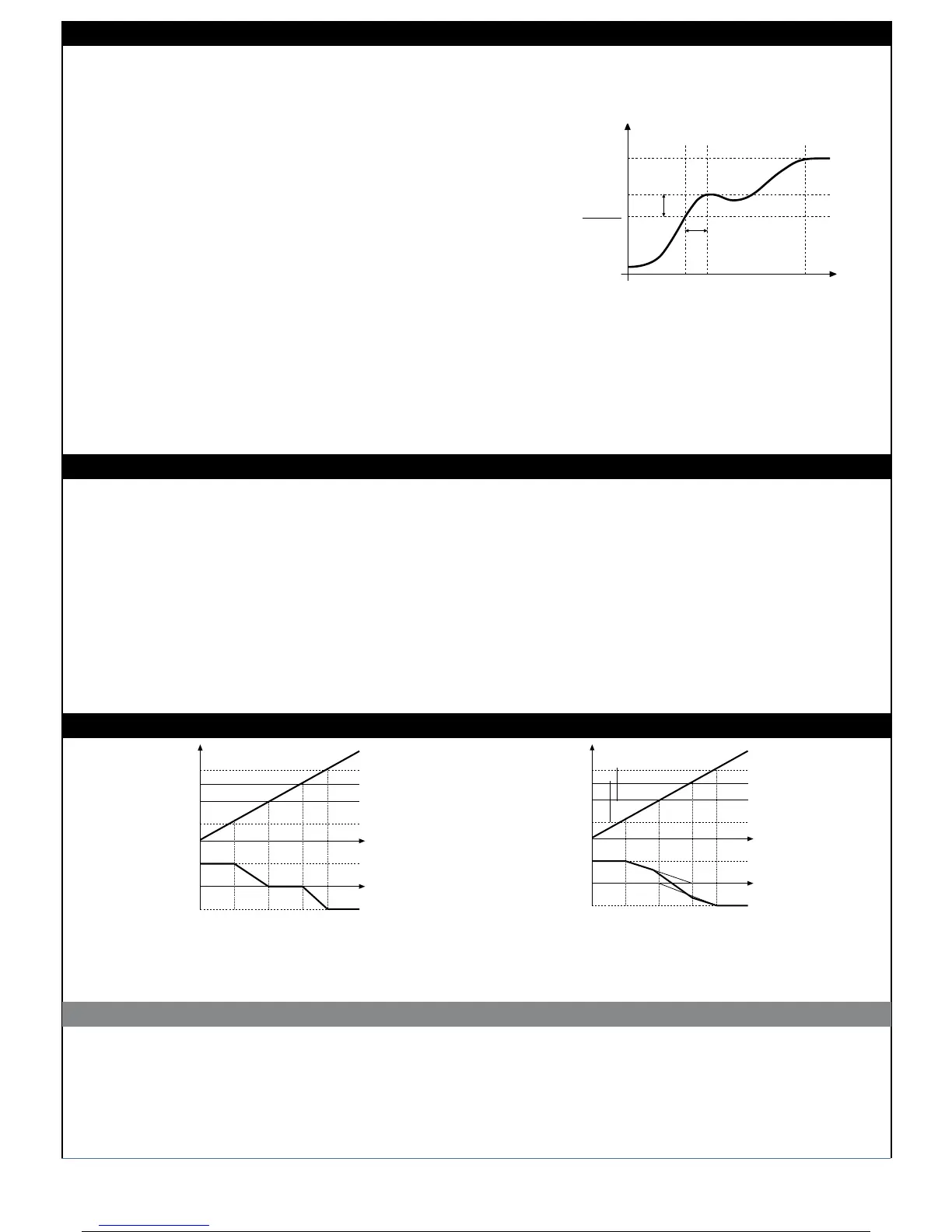

The function works for single output systems (heating or cooling). The self-tuning action calculates optimum control parameter values during

process startup. The variable (for example, temperature) must be that assumed at zero power (room temperature).

The controller supplies maximum power until an intermediate value between starting value and setpoint is reached, after which it zeros power.

PID parameters are calculated by measuring overshoot and the time needed to reach peak. When calculations are finished, the system

disables automatically and the control proceeds until the setpoint is reached.

How to activate self-tuning:

A. Activation at power-on

1. Set the setpoint to the required value

2. Enable selftuning by setting the Stun parameter to 2 (CFG menu)

3. Turn off the instrument

4. Make sure the temperature is near room temperature

5. Turn on the instrument again

B. Activation from keyboard

1. Make sure that key M/A is enabled for Start/Stop selftuning (code but = 6 Hrd menu)

2. Bring the temperature near room temperature

3. Set the setpoint to the required value

4. Press key M/A to activate selftuning (Attention: selftuning interrupts if the key is pressed again)

The procedure runs automatically until finished, when the new PID parameters are stored: proportional band, integral and derivative times

calculated for the active action (heating or cooling). In case of double action (heating or cooling), parameters for the opposite action are

calculated by maintaining the initial ratio between parameters (ex.: CPb = HPb * K; where K = CPb / HPb when self-tuning starts). When

finished, the Stun code is automatically cancelled.

Notes :

-The procedure does not start if the temperature is higher than the setpoint (heating control mode) or if the temperature is lower than the

setpoint (cooling control mode). In this case , the Stu code is not cancelled.

-It is advisable to eneable one of the configurable LEDs to signal selftuning status.By setting one of parameters

LED1, LED2, LED3=4 or 20 on the Hrd menu, the respective LED will be on or flashing when selftuning is active.

12 • SELF-TUNING

Peak

T

S.P.

t.a.

Time

Process

Variable

S.P. + t.a.

2

13 • AUTO-TUNING

Enabling the auto-tuning function blocks the PID parameter settings.

It can be one of two types: permanent (continuous) or single-action (one-

shot).

* Continuous auto-tuning is activated via the Stu parameter (values 1,

3, 5). It continuously reads system oscillations, immediately seeking

the PID parameter values that reduce the current oscillation. It does

not engage if the oscillations drop below 1.0% of the proportional band.

It is interrupted if the set-point is changed, and automatically resumes

with a constant set-point. The calculated parameters are not saved if

the instrument is switched off, if the instrument is switched to manual,

or if the configuration code is disabled. The controller resumes with the

parameters programmed before auto-tuning was enabled. The calculated

parameters are saved when the function is enabled from the digital input

or from the A/M (start/stop) key if the procedure is interrupted.

* One-shot auto-tuning can be enabled manually or automatically. It is

activated via the Stu parameter (as can be seen on the table, the values

to be set depend on whether Self-tuning or Soft-start is enabled.). It is

useful for calculation of PID parameters when the system is around the

set-point. It produces a variation on the control output at a maximum of

± 100% of the current control power limited by h.PH - h.PL (hot), c.PH -

c.PL (cold), and assesses the effects in timed overshoot. The calculated

parameters are saved. Manual activation (Stu code = 8, 10, 12) via direct

setting of the parameter or via digital input or via key. Automatic activation

(Stu code = 24, 26, 28 with error band of 0.5%) when the PV-SP error

exceeds the preset band (programmable to 0.5%, 1%, 2%, 4% of full

scale).

NB: at power-up, or after a change of set-point, automatic activation is

inhibited for a time equal to five times the integral time, with a minimum of

5 minutes. The same time has to run after one-shot.

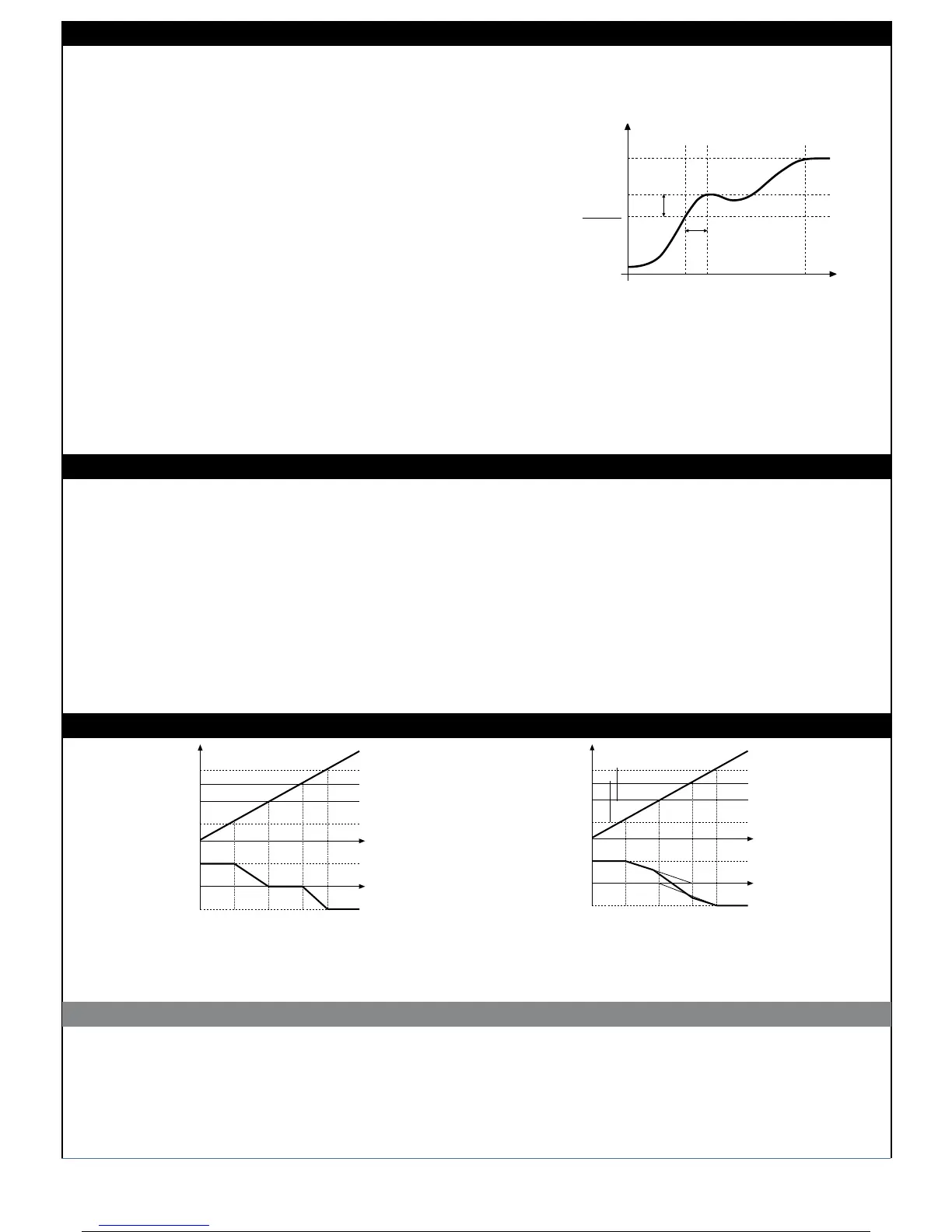

time

PV

c_Pb

h_Pb

SP+cSP

SP

+100%

Control output

0%

-100%

Control output with proportional action only if proportional heating band

overlaps proportional cooling band.

Control output with proportional action only if proportional heating band

overlaps proportional cooling band.

time

PV

c_Pb

h_Pb

SP+cSP

SP

+100%

Control output

0%

-100%

PV = Process Value SP = Heating Setpoint

SP+cSP = cooling setpoint h_Pb = proportional heating band

c_Pb = Proportional cooling band

14 • CONTROLS

In this control mode (enabled with Ctr = 14 parameter) the type of cooling has to be specified.

Cooling PID parameters are therefore calculated based on heating parameters according to the specified ratio.

(for example: C.ME = 1 (oil), H_Pb = 10, H_dt = 1, H_It = 4 implies: C_Pb = 12,5, C_dt = 1, C_It = 4)

We advise you to apply the following values when setting output cycle times:

Air T Cool Cycle = 10 sec. Oil T Cool Cycle = 4 sec Water T Cool Cycle = 2 sec.

NB.: Cooling parameters cannot be modified in this mode.

Heating/Cooling control with relative gain

14 80336L_MHW_600_07-2011_ENG

14 / 31

Loading...

Loading...