BLIZZARD 400-800 C ENC 28 532104 - Rev.A

8

46

Translation of the original instructions

ENGLISH

7.8 SET-UP

!

During Setup, the photocells and the safety edges are disabled; prevent

transit in the area of movement of the gate.

Li

The flashing S0 code on the display indicates that the Setup procedure

must be carried out.

Any Bus devices that are connected are registered during the Setup

procedure.

The Setup procedure can be interrupted by using the STOP command.

If a MASTER-SLAVE configuration is used, carry out the Setup procedure

after having read § 10.

1. Bring the gate to its halfway position following the instructions

in § 5.5. Restore automatic operation.

2. Go to function

tL in Basic Programming.

3. Press and hold down the

+ and

-

buttons until the gate starts

to close.

4. Release the

+ and

-

buttons. The Setup procedure will continue

independently. Check the following conditions:

DISPLAY PHASE

S1

Gate closing movement

S2

Closing limit switch engaged.

S3

Gate opening movement.

S4

Opening limit switch engaged.

01

Setup procedure completed. Gate open.

8. FINAL OPERATIONS

RISKS

PERSONAL PROTECTIVE EQUIPMENT

1. Make sure that the forces generated by the leaf are within the

limits permitted by the current regulations. Use an impact force

tester in accordance with standards EN 12453 and EN 12445. For

non-EU countries, of there are no specific local regulations, the

force must be less than 150 N.

2. Check that the maximum force required to move the leaf by hand

is less than 150 N.

3. Highlight all areas with adequate warning signs in which there

are still residual risks, even if all possible safety measures having

been adopted.

4. Place a “DANGER, AUTOMATICALLY CONTROLLED” sign in a promi-

nent position on the gate.

5. Attach the CE marking to the gate.

6. Fill out the EC declaration of conformity and the system register.

7. Give the EC Declaration, the system register with the maintenance

plan and the instructions for use of the automation system to the

system owner/operator.

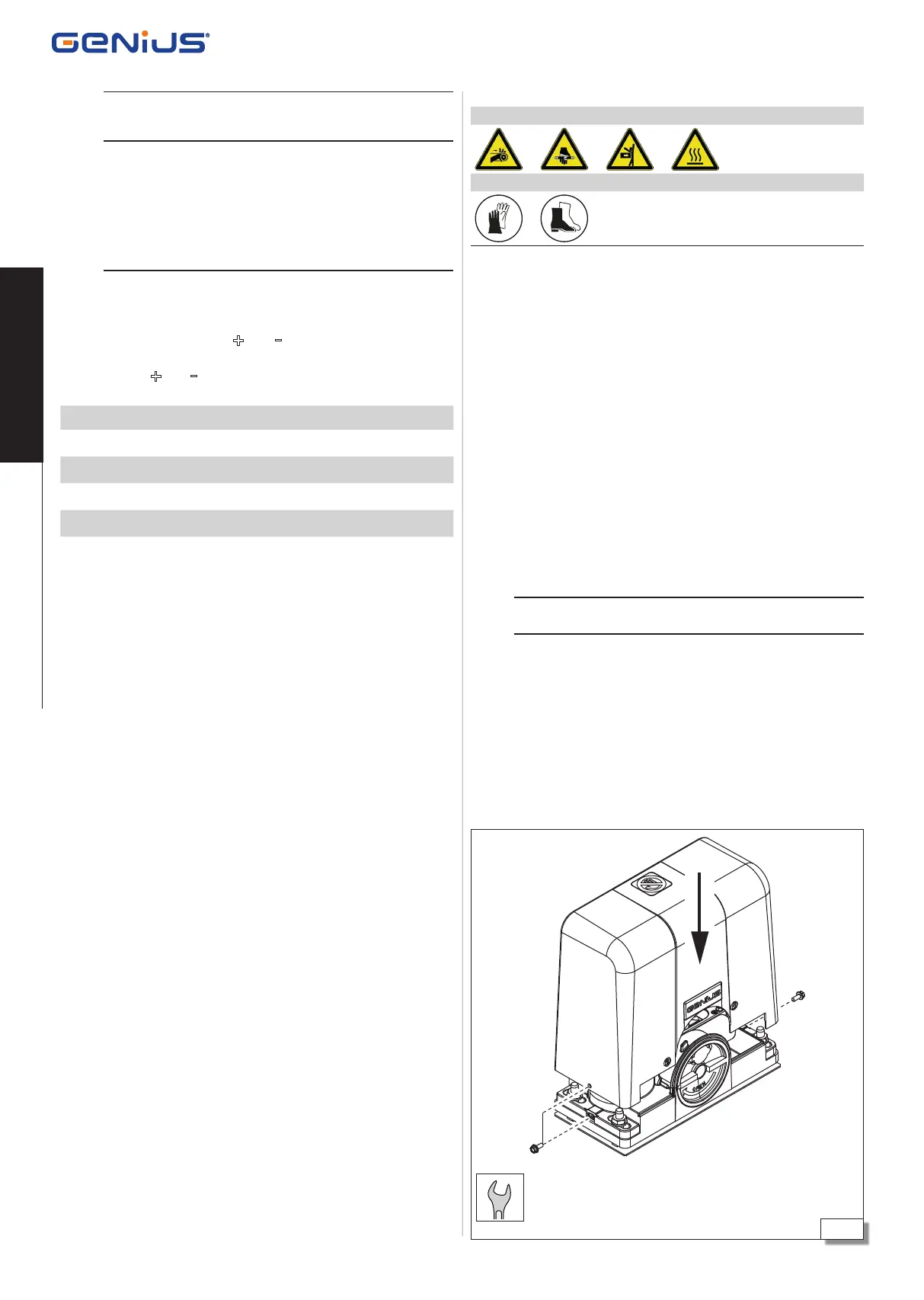

INSTALLING THE CASING

!

Install the cover 46: using the M5X12 hexagonal head or Allen

screws provided.

Loading...

Loading...