Class II, Type A2 Biosafety Cabinet

User Manual

6

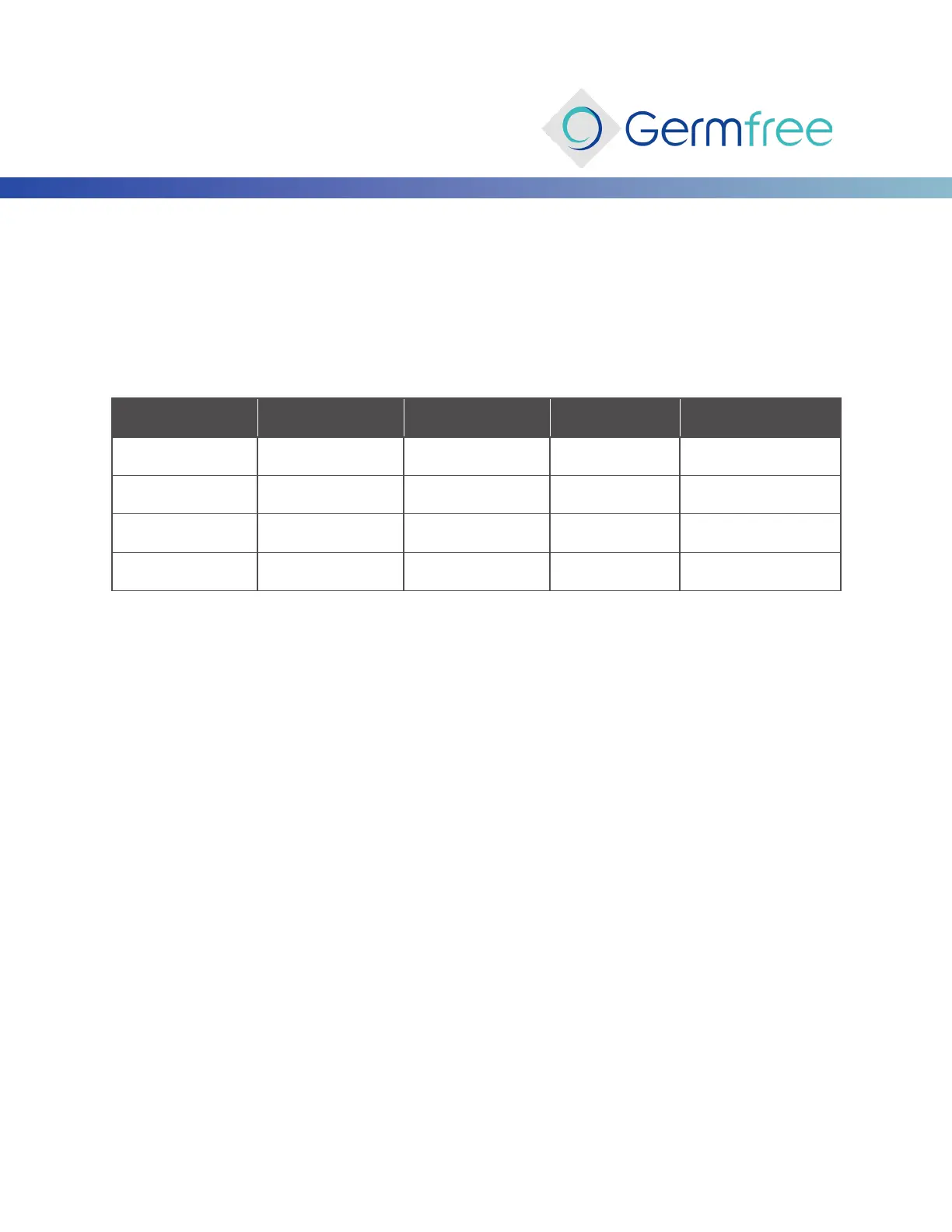

Control of Airflow

To be sure your unit is functioning properly, the air velocity should be measured directly by a qualified third party

certification professional. Readings of air velocity, measured in feet per minute, can be made with a velometer

or thermoanemometer to determine if the unit is within specification and when the filters should be changed.

This certification should be performed at least annually, and many regulatory bodies recommend semi-annually.

The unit must also be recertified any time that it is relocated. The following chart represents the acceptable

range of air velocities that are measured in your unit.

Unit Inflow (fpm) Downflow (fpm) Volume (cfm) Exhaust Flow (fpm)

BBF 2 87-102 65-80 114-134 154-181

BBF 3 102-112 67-82 147-161 123-134

BBF 4 102-112 67-82 215-236 130-142

BBF 6 102-112 70-85 353-388 106-117

Eventually, the HEPA filters will be loaded with particulates to a point where the blower can no longer overcome

the resistance to provide the proper air velocities. At this point new HEPA filters must be installed. Replacement

HEPA filters can be ordered ahead of time so that they are available in advance of changing. Because viable

particles may be trapped and survive for a period of time in the filters, the Class II, Type A2 Biosafety Cabinet

must be decontaminated, if any biological agents have been manipulated within the cabinet, before any HEPA

filters are changed.

A low flow alarm will indicate when the inflow has fallen below acceptable levels. This can indicate that

maintenance needs to be performed on the cabinet.

Loading...

Loading...