Installation Manual Series CF (without incapsulated screw compressors) 23042013 Rev. A / May 2007 18 of 60

4.6 Recommendations for

Lubricants

4.6.1 Type of lubricants

In consideration of the high stresses to which

lubricants are subjected in screw compressors

with oil injected cooler, it is recommended to ex-

clusively use non-aging and anti-corrosive oil

grades with a low foaming tendency that have

been demonstrated to be suitable for application.

GHH RAND recommend stable and proven char-

acteristic lubricants:

„PrimeCool“ on mineral basis &

„PrimeCool Plus“ on synthetic basis.

In case of utilisation of another lubricant, it is

mandatory that oil specification as follows must

be observed.

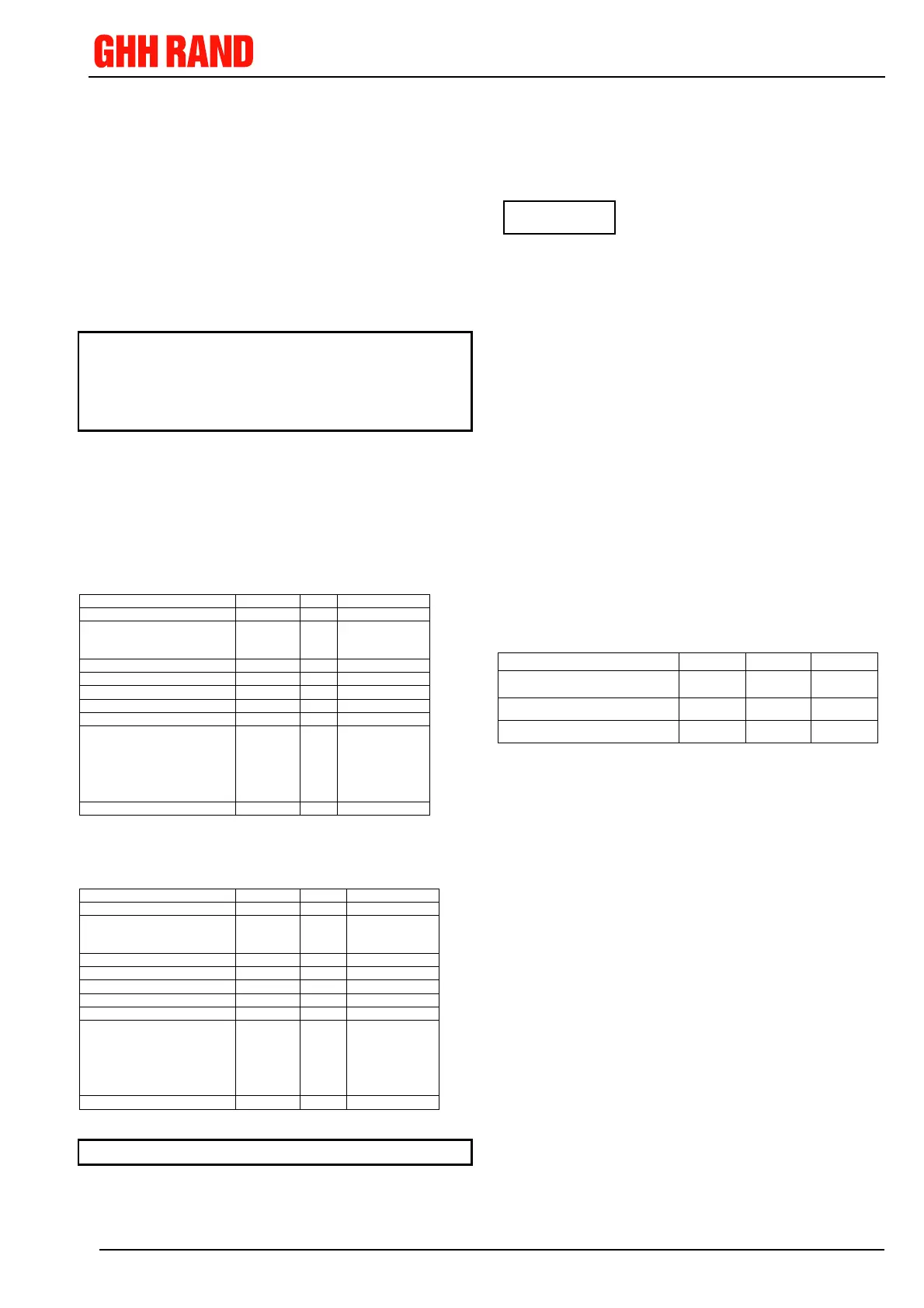

Technical specification of PrimeCool (mineral

lubricant)

Properties Unit Test method

Density at 15 °C kg/m3 874 DIN 51 757

Kinematic viscosity

at 40 °C

at 100 °C

mm

2

/s

46

6,8

DIN 51 550 &

DIN 51 562-1

Viscosity index 101 DIN ISO 2909

Flashpoint °C 230 DIN ISO 2592

Pourpoint °C -31 DIN ISO 3016

Neutralization number TAN mgKOH/g 0,2 DIN 51 558-2

Demulsification at 54 °C min 15 DIN 51 599

Foaming

Seq.I: 24 °C

Seq.II: 93,5 °C

Seq.III after 93,5 °C

ml/ml

ml/ml

ml/ml

0/0

20/

0

5/0

ASTM D 892

ASTM D 892

ASTM D 892

Air release at 50° C min 3 DIN 51 381

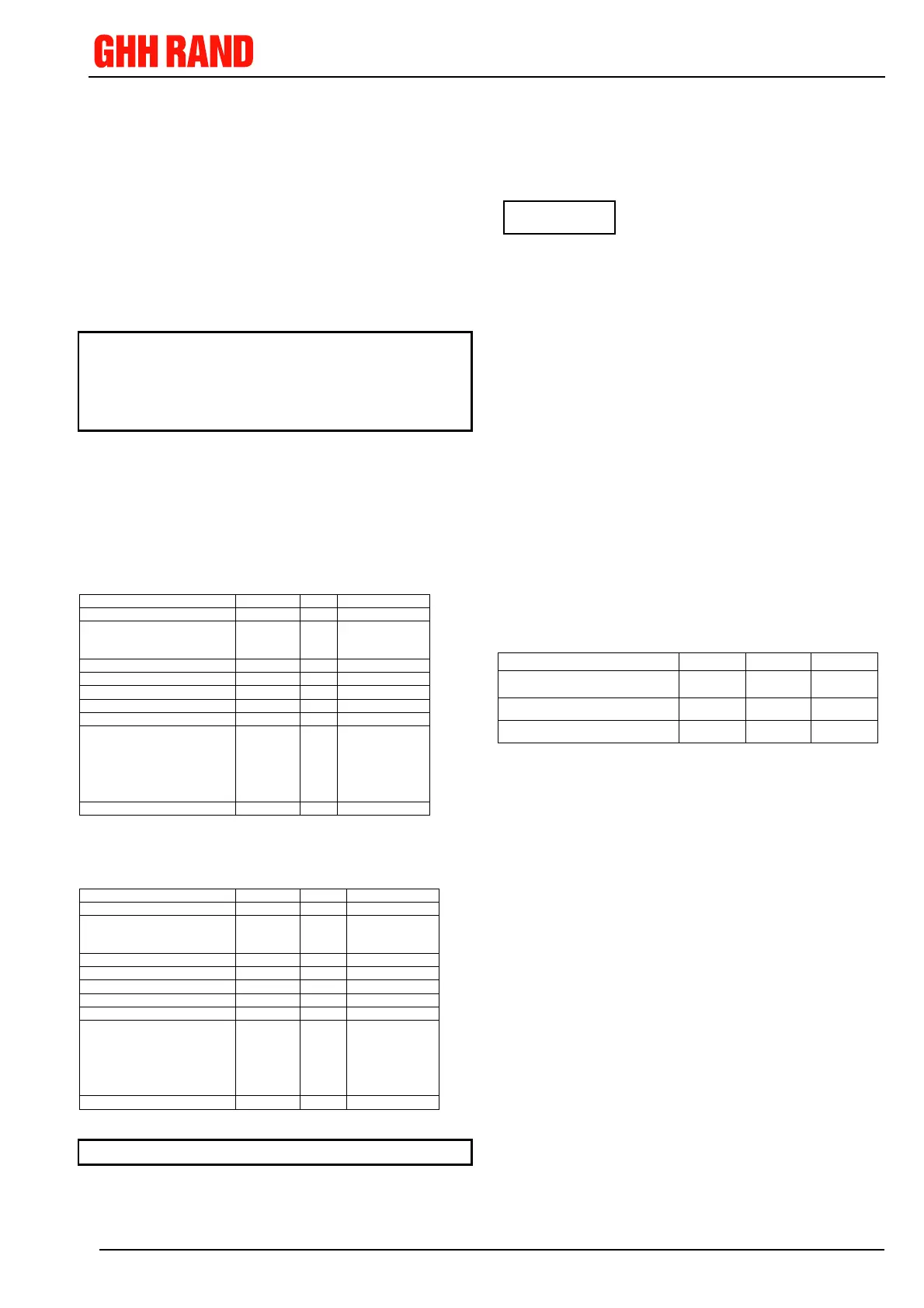

Technical specification of PrimeCool Plus (syn-

thetic lubricant)

Properties Unit Test method

Density at 15 °C kg/m3 837 DIN 51 757

Kinematic viscosity

Bei 40 °C

Bei 100 °C

mm

2

/s

46

7,8

DIN 51 550 &

DIN 51 562-1

Viscosity index 139 DIN ISO 2909

Flashpoint °C 278 DIN ISO 2592

Pourpoint °C <-60 DIN ISO 3016

Neutralization number TAN mgKOH/g 0,4 DIN 51 558-2

Demulsification at 54 °C min 15 DIN 51 599

Foaming

Seq.I: 24 °C

Seq.II: 93,5 °C

Seq.III: after 93,5 °C

ml/ml

ml/ml

ml/ml

5/0

20/0

5/0

ASTM D 892

ASTM D 892

ASTM D 892

Air release at 50° C min 3 DIN 51 381

Different specifications will lead to non-warranty!

As deterioration of lubricant strongly depends on

conditions of the airborne area and the operating

method of the compressor, regular checks of the

oil quality have to be carried out and docu-

mented. In either case the interval of oil change

has to be observed according to maintenance

instructions.

In case of utilisation of synthetic lubricants, com-

patibility with compressor component material

has to be ensured. Furthermore oil additives

within the oil must not chemically react to the

condensate which is unavoidably developed at

start-up of compressor unit.

Authorisation for other lubricants other than

PrimeCool / PrimeCool Plus will not be given!

4.6.2 Lubricant selection

Viscosity is the most important criterion of any

lubricant. To avoid damage to the bearings, a

minimum viscosity of 15 mm²/s (cSt) is required

for the selected oil injection temperature. As vis-

cosity changes with temperatures, the recom-

mendations as per the following table are appli-

cable depending on respective injection tempera-

tures:

Injection temperature °C up to 50 up to 60 up to 70

ISO-Viscosity class

VG 32 VG 46 VG 68

Viscosity at 40 °C mm²/s 28.8-35.2 41.4-50.6 61.2-74.8

Flashpoint COC °C >200 >210 >220

The pour point is min. 5 °C below the lowest am-

bient temperature.

On machinery which is continuously operated at

very low speeds (male-rotor tip speed less than

15 m/s), the respective next higher viscosity

class is to be used in accordance with the above

table.

To avoid wearing effects on antifriction bearings

and driving gears to the greatest possible extent,

only those oil grades are accepted which contain

wear-reduction additives to provide FZG load

stage no. 10 as a minimum.

Loading...

Loading...