39

12 Commissioning

13895

12.3 Filling Domestic Water Circuit

Fully open any valves in the domestic water supply to the

boiler.

Open the domestic water isolation valve, slot in line with the

length of the valve (shown closed in diagram).

Open all hot water taps in turn and close them when water

ows. Check for water soundness of the complete domestic

water system.

The water ow rate is restricted by a restrictor factory tted to

the boiler.

12.4 Re-pressurising System

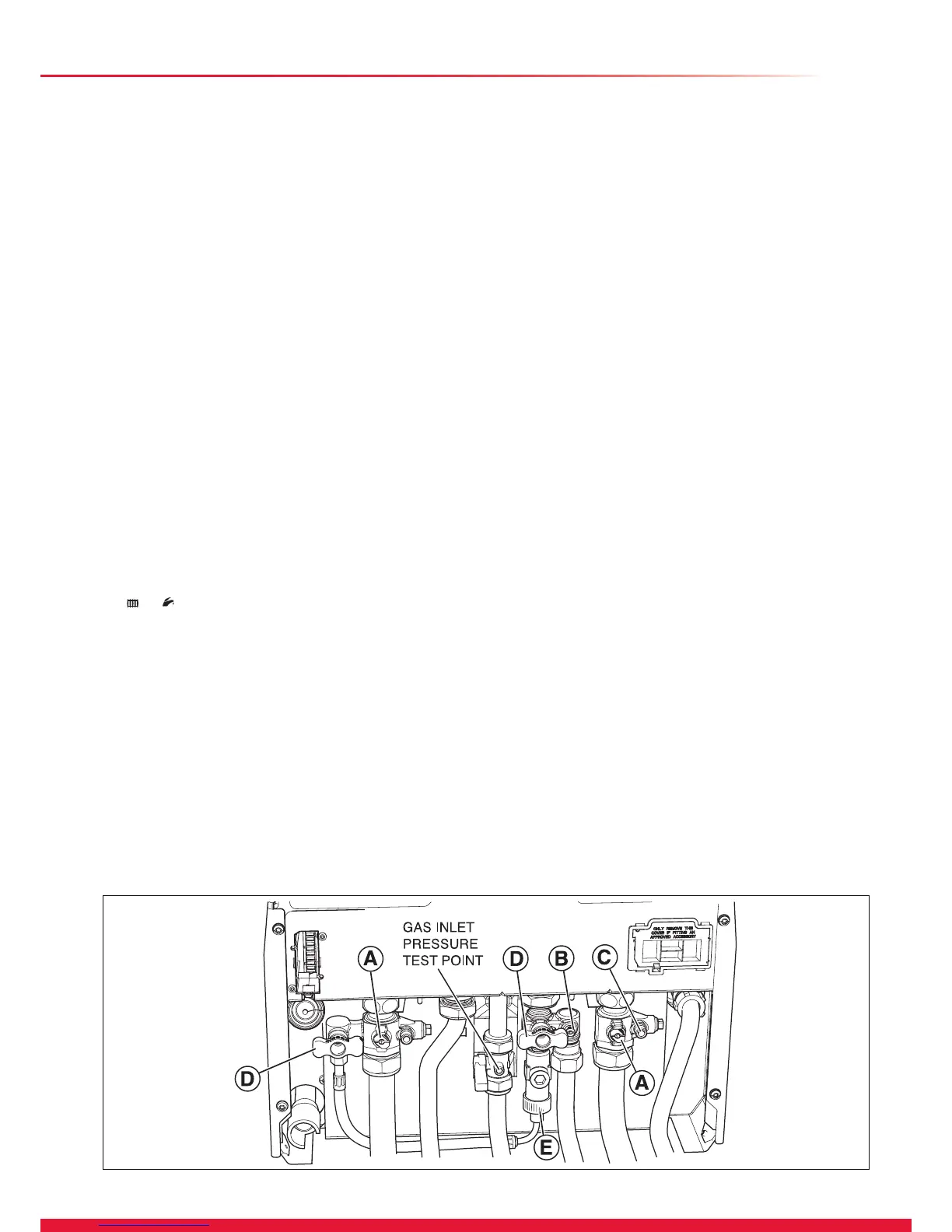

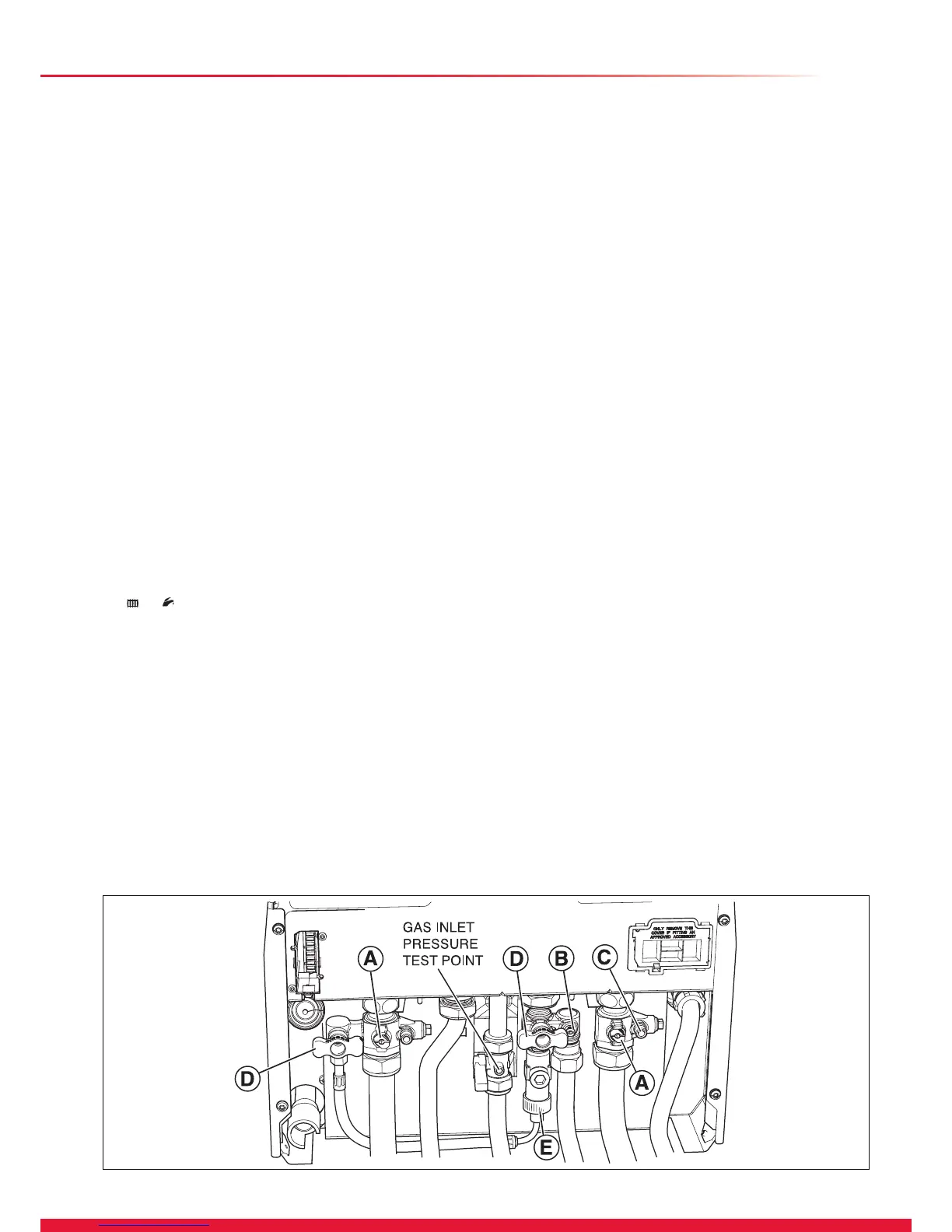

1. Ensure that the exible hose is connected to the double

check valve by tightening the knurled nut marked ‘E’.

2. Open the two lling taps marked ‘D’ by rotating them

through 90

O

to ll the heating system to a pressure of

1.0bar. Close the two lling taps marked ‘D’.

3. Vent all air from the system - repeat step 2 as neccessary

until the system is full and all the air has been removed.

4. To comply with the water regulations the exible hose must

be disconnected from the double check valve - undo the

knurled nut marked ‘E’ and pull the exible hose from the

double check valve.

12.5 Gas Supply

The gas valve is factory set for natural gas (G20) and should

need no adjustment. Turn on the gas supply at the isolation

valve, see diagram 12.1. Check the supply pressure at the

pressure test point is 20mbar.

Commissioning should only be carried out by a competent

person approved at the time by the Health and Safety

Executive.

12.6 Initial Lighting

NOTE: The combustion for this appliance has been

checked, adjusted and preset at the factory for operation

on natural gas (G20) as dened on the appliance data

label.

Do not adjust the Gas/Air ratio valve.

No measurement of the combustion is necessary, having

checked :

● the appliance has been installed in accordance with the

instructions.

● the integrity of the ue system and ue seals.

● that all internal/external controls are calling for heat.

● the gas service isolation valve, diagram 12.1, is open.

Diagram 12.1

5. Open the two lling taps marked ‘D’ by rotating them

through 90° to ll the heating system to a pressure of

1.0bar. Close the two lling taps.

6. Vent all air from the system - repeat step 5 as neccessary

until the system is full and all the air has been removed.

7. Close the Domestic Cold Water isolation valve marked

‘B’ using a screwdriver or a 3mm allen key (shown closed

in diagram).

8. Close the Central Heating Flow and Return isolation

valves marked ‘A’ using a screwdriver or a 4mm allen key

(shown closed in diagram). If the manometer kit was used,

close drain point marked ‘C’ and remove the manometer.

9. To comply with the water regulations the exible hose

must be disconnected from the double check valve - undo

the knurled nut marked ‘E’ and pull the exible hose from

the double check valve.

12.2 Filling the System and Boiler

1. Ensure that the exible hose is connected to the double

check valve by tightening the knurled nut marked ‘E’.

2. Open the Central Heating Flow and Return isolation valves

marked ‘B’ using a screwdriver or a 4mm allen key - slot

in line with the axis of the isolation valve (shown closed in

diagram).

3. Open the Domestic Cold Water cock marked ‘B’ using a

screwdriver or a 3mm allen key - slot in line with the axis

of the isolation valve (shown closed in diagram).

4. Switch on the appliance, refer to diagram 12.2.

Set the Central Heating temperature and the Domestic Hot

Water temperature to OFF by pressing the MODE button

on the User Interface until it shows the appropriate symbol

and then pressing the - (minus) SELECTOR

button.

The display will now permanently show system pressure.

5. Open the two lling taps marked ‘D’ by rotating them

through 90

O

to ll the heating system to a pressure of

1.0bar. Close the two lling taps marked ‘D’.

6. Vent all air from the system - repeat step 5 as neccessary

until the system is full and all the air has been removed.

7. After lling is complete set the Central Heating

temperature and the Domestic Hot Water temperature

to the desired level using the MODE and + (plus)

SELECTOR buttons as described above.

8. To comply with the water regulations the exible hose

must be disconnected from the double check valve - undo

the knurled nut marked ‘E’ and pull the exible hose from

the double check valve.

Loading...

Loading...