43

221469B

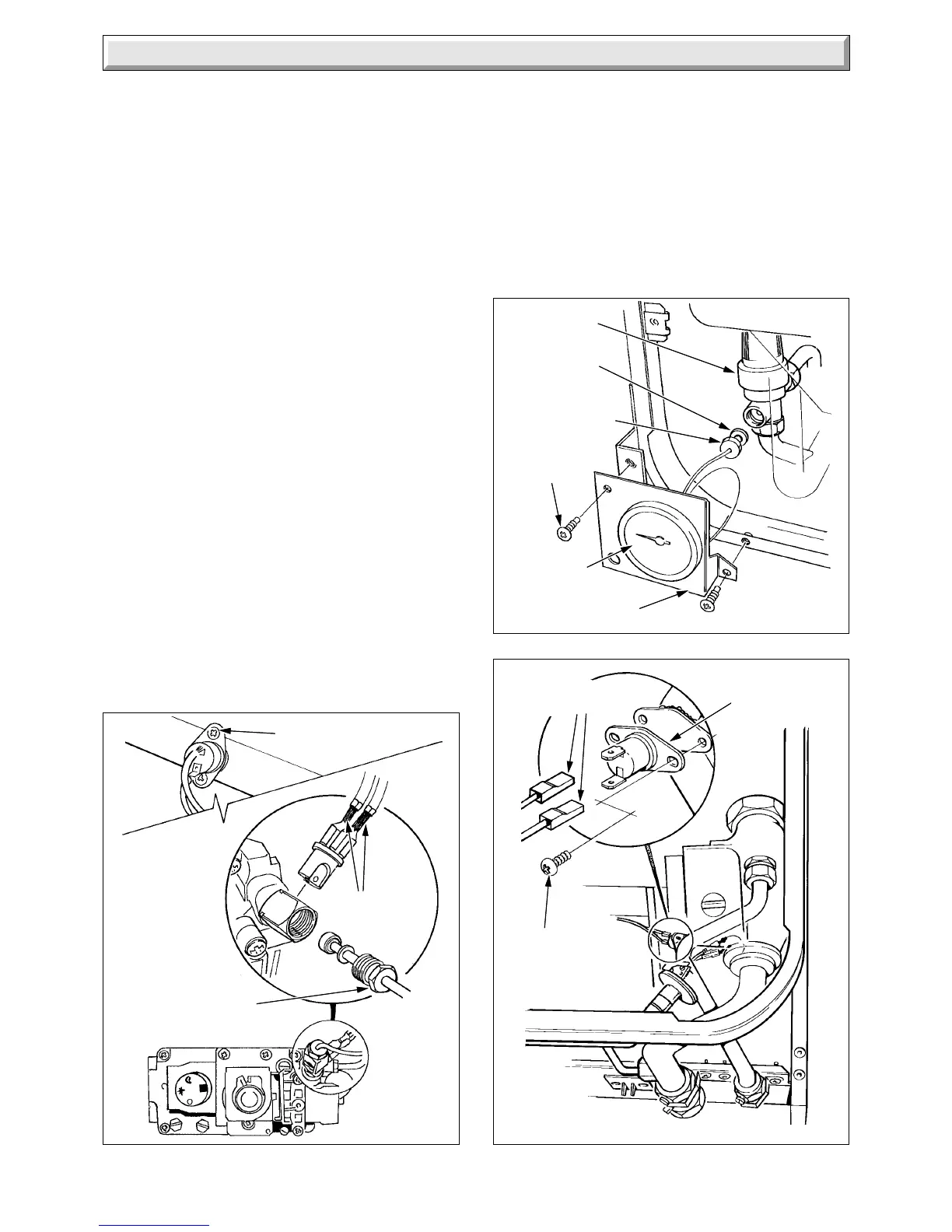

Diagram 4.7

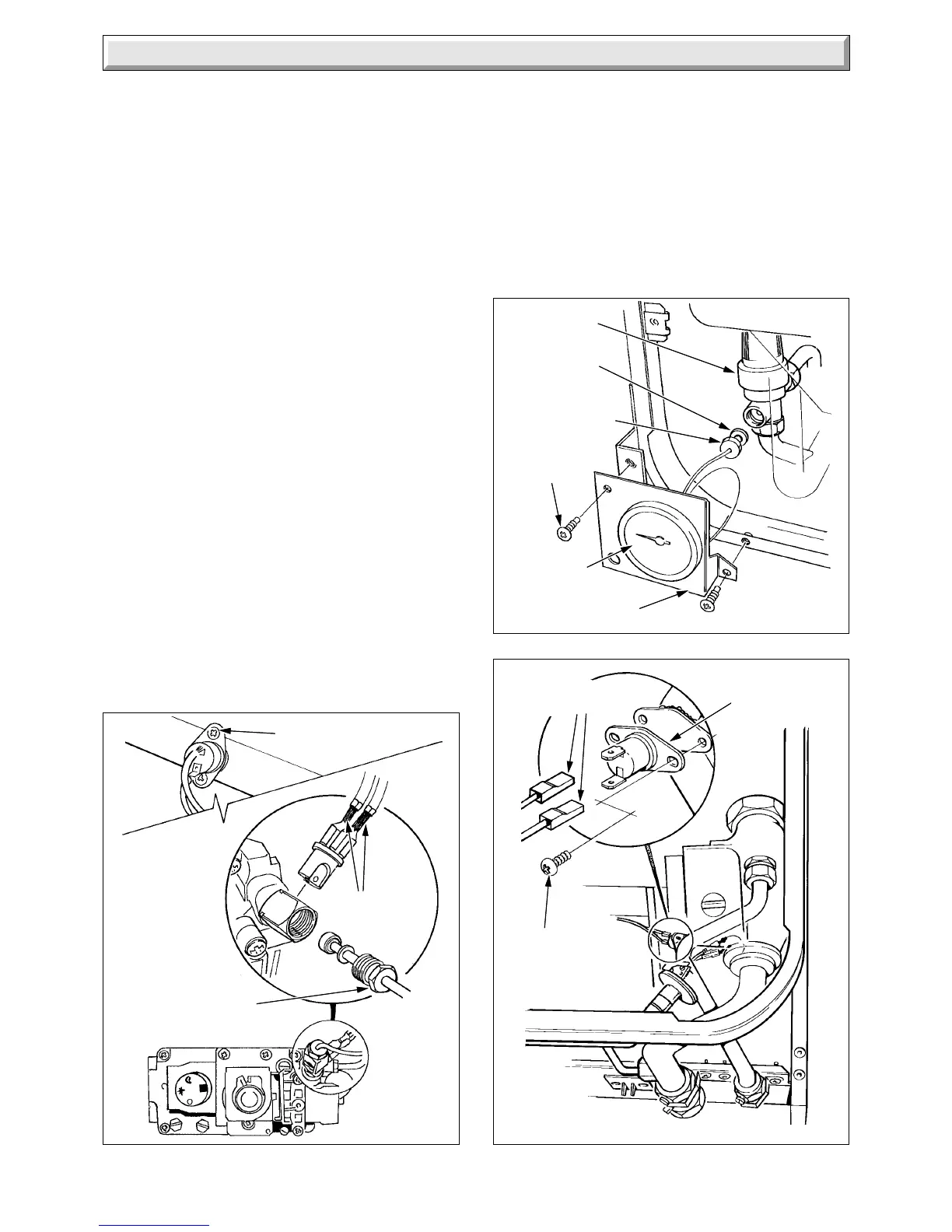

Diagram 4.8

4 Replacement of Parts

2831 S

4449 S

PRESSURE

GAUGE

SAFETY

VALVE

SEALING

WASHER

PRESSURE

GAUGE

CONNECTION

SECURING

SCREW (2)

PRESSURE

GAUGE BRACKET

SECURING

SCREW (2)

ELECTRICAL

CONNECTORS

D.H.W. HIGH

LIMIT CONTROL

Diagram 4.6

SIT

2865 S

ELECTRICAL

CONNECTORS

SECURING

SCREW (2)

THERMOCOUPLE

NUT

Disconnect the pressure gauge connection from the safety

valve, discard the sealing washer.

Remove the pressure gauge secured with the retaining spring

tabs.

Locate the supplied sealing washer under the pressure gauge

connection when it is fitted to the safety valve.

Make up the water loss and pressurise the system, refer to

Commissioning in the Installation Instructions.

4.13 Control Boards

Before starting refer to Section 1.1.

Isolate the boiler from the electrical supply, refer to Section 1.3.

Remove the outer case, refer to Section 1.4.

Remove the clock mounting bracket securing screws, see

diagram 4.8A.

Remove control housing cover, temperature control knob and

the fascia, see diagram 4.5.

Remove the control housing assembly, see Section 4.13.

Disconnect all the multi-pin connectors, see diagram 4.9.

Remove the control boards from the support post, noting the

correct positions. Great care must be taken when handling any

control board.

THEY MUST BE KEPT IN THE ANTI-STATIC HOLDER UNTIL

IMMEDIATE REQUIREMENT.

To connect the multi-pin connector correctly, see diagram 4.10.

Check and adjust the main burner gas pressure in the hot water

and central heating modes, if necessary, refer to Commissioning

in the Installation Instructions.

4.14 Clock/Timer - if fitted

ELECTRO/MECHANICAL and DIGITAL clock/timer - Release

the mounting bracket securing screws, see diagram 4.8A.

Disconnect electrical cables, release securing clip to remove

the clock timer and spacer, see diagram 4.8B.

Loading...

Loading...