Commander III

2-15

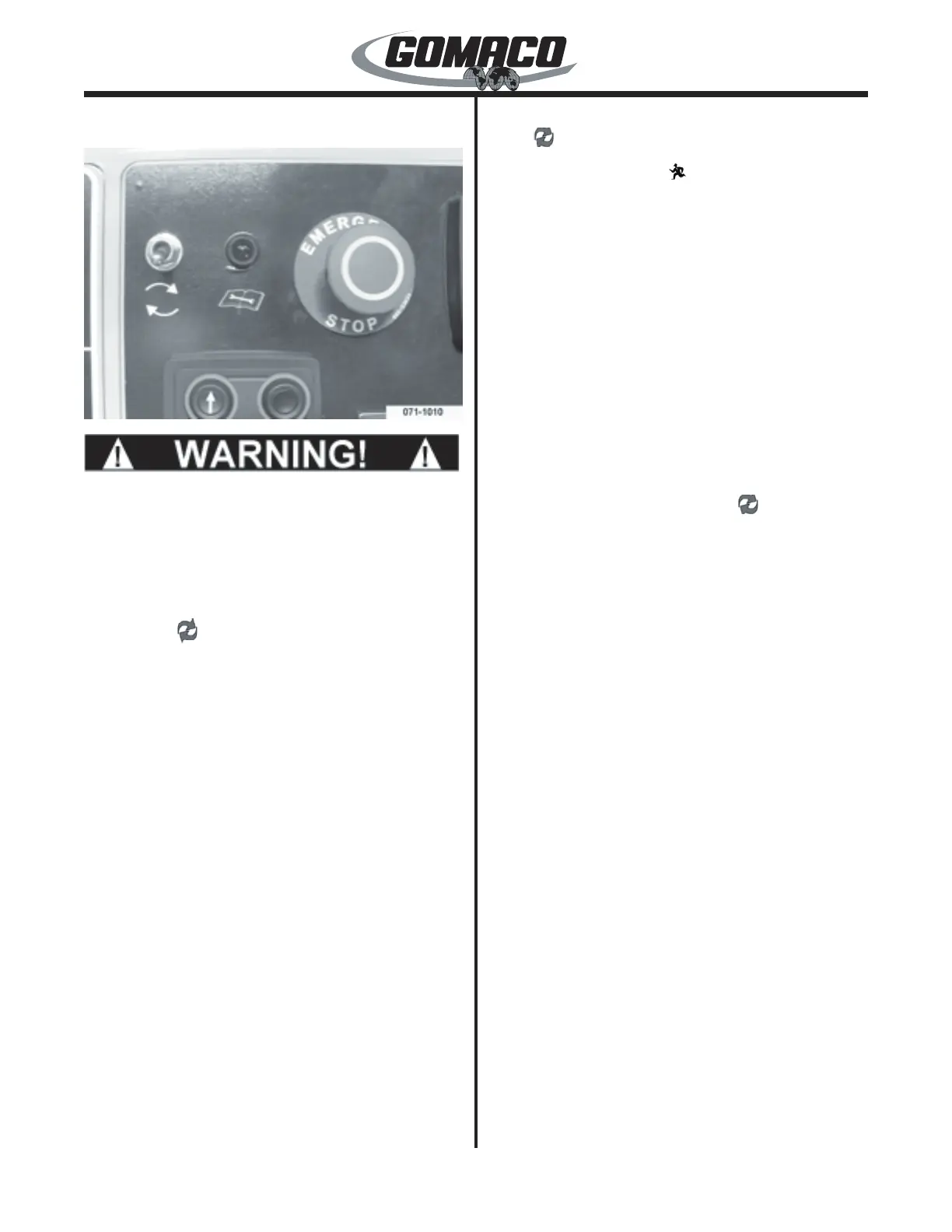

06―G+ Control Panel

071-1010

0044

A defective emergency stop system may cause

severe injury or death. Do not operate the

machine with an inoperative emergency stop

system. Check the emergency stop system daily

for proper working order before beginning paving

operations.

Fault Reset ( ) Switch: Used to reset the controller

when a fault has been detected. The reset switch

should be activated (moved upward and released)

whenever the fault/standby indicator lamp is

illuminated. If the lamp is ashing, refer to the fault/

standby indicator lamp explanation below.

Emergency stop switches must be reset and all faults

must be removed prior to activating the fault reset

switch. The controller will distinguish faults as minor

or critical faults. Minor faults require the repair of the

fault, pushing the fault reset switch to remove the

active fault and pressing the run/standby switch to

resume pouring operations at the previous settings.

Critical faults require all potentiometers and direction

switches be returned to the “off” or “neutral” position

before resetting the controller. Refer to the controller

active fault display for more information.

Note: Placing a faulted control loop in manual

(M) may allow manual operation of the system

depending upon the type of fault detected.

Fault/Standby Indicator Lamp: Used to indicate

when a fault occurs in the control system or when the

controller is in “standby” mode. If a fault is detected,

the lamp will remain illuminated and the controller

will stop all machine functions. If the controller is in

“standby” mode, the lamp will ash. Activate the fault

reset ( ) switch to reset the system. If all faults have

been corrected, the lamp will ash. The ashing lamp

will go out when the Run ( ) switch is depressed.

Note: The fault/standby indicator lamp will be

illuminated after initial start up of the engine as

well as whenever an emergency stop switch has

been depressed.

Emergency Stop Switch: Used to stop all functions

on the machine. Emergency stop switches are located

on the control console and on each elevation leg (two

emergency stop buttons are possible on each leg).

The switches must all be pulled out to operate the

machine. If any switch is depressed, the machine

travel, trimmer, auger/conveyor, vibrators and lift

circuits will be deactivated. Refer to the active fault

display (see later) to determine which E-stop switch is

at fault (depressed). After the emergency stop switch

is pulled out (reset), it will be necessary to reset the

system by activating the fault reset ( ) switch. Make

certain all controls are in the "off" or "neutral" position

before resetting the emergency stop system. To

resume travel in either direction, place the controller

in the "run" mode, depress the desired travel direction

switch and rotate the travel variable control dial to the

desired setting.

Note: All emergency stop switches must be pulled

out to operate the machine. The operation of the

emergency stop system must be checked every

day before beginning operation.

Loading...

Loading...