TORQUE TO

6.87.9

Nm

(6-6.8

ft-lb)

23

24

22

TORDUETO

3.44.5

Nm

12.63.3ft-lbJ

APPLY LOCTITE"

NO.

222

TO

THREADS

L41

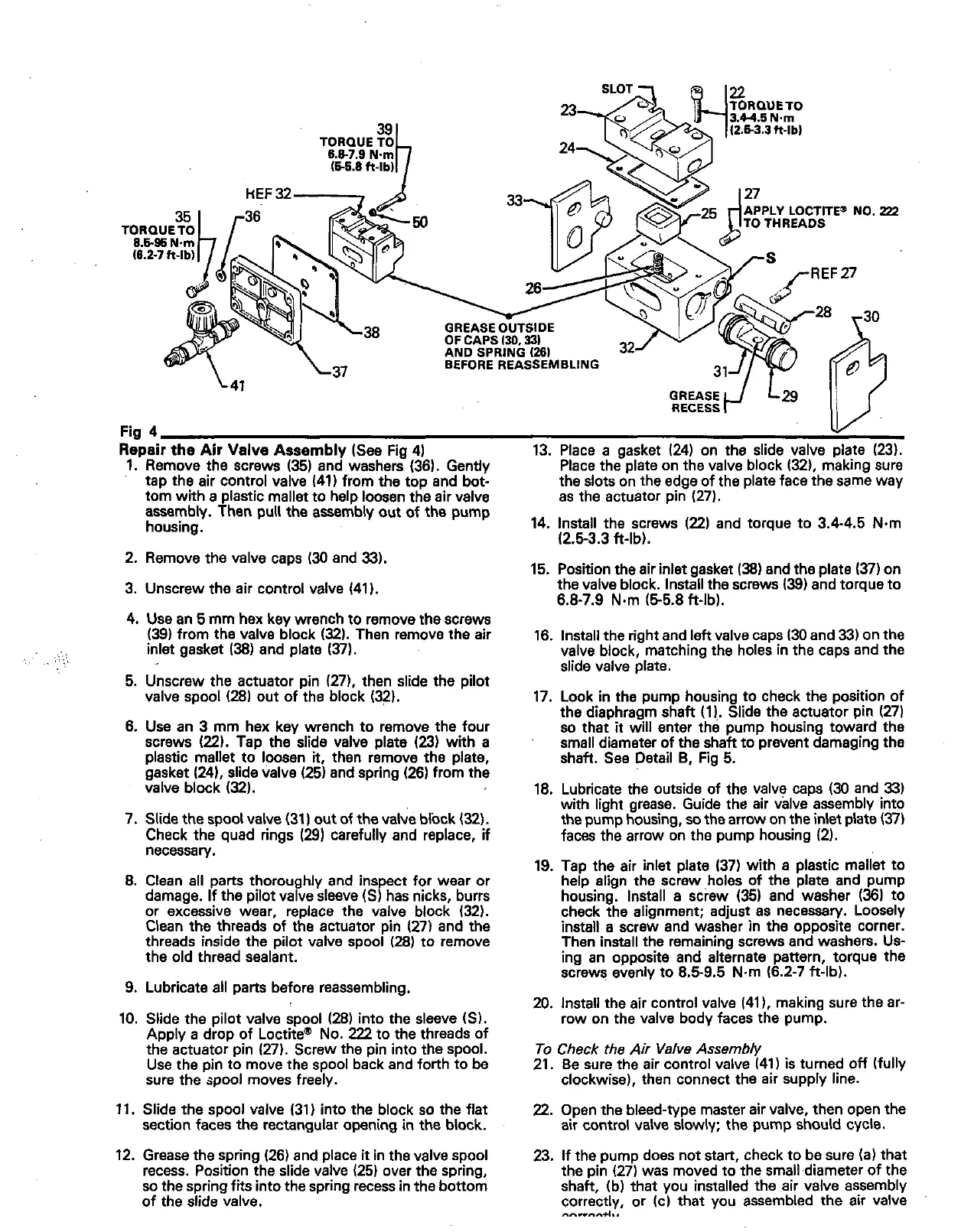

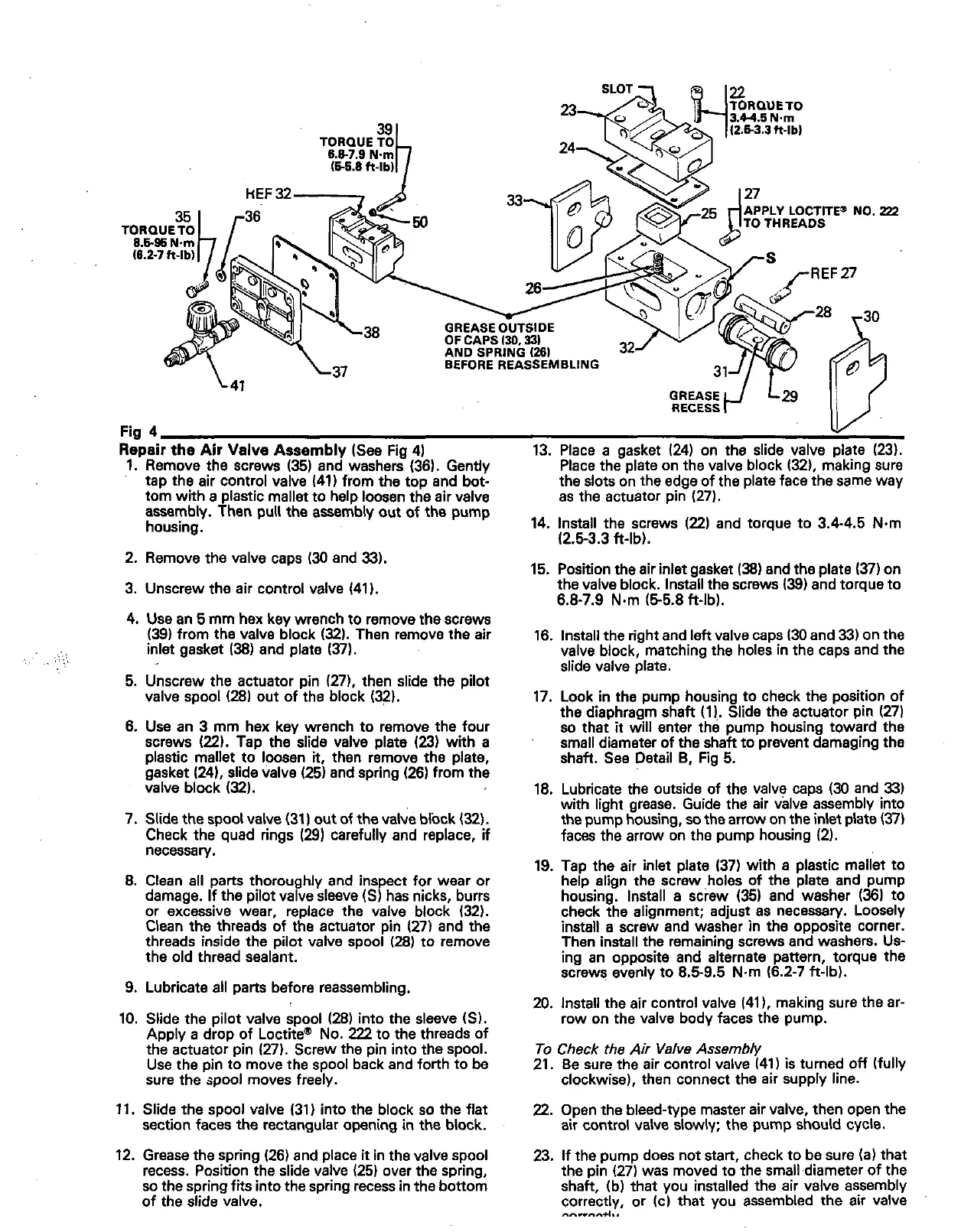

Repair the Air Valve Assembly (See Fig 4)

Fig

4

1.

Remove the screws

(35)

and washers (36). Gently

tap the

air

control valve

(411

from the top and bot-

tom with

a

plastic mallet to help loosen the air valve

assembly. Then pull the assambly out of the pump

housing.

2.

Remove the valve caps

(30

and

33).

3. Unscrew the

air

control valve (41

I.

4.

Use an

5

mm hex key wrench to remove the screws

(39)

from the valve block

(32).

Then remove the air

inlet gasket

(38)

and plate

(37).

..

....

.

:;.

5. Unscrew the actuator pin (271, then slide the pilot

valve spool

(28)

out of the block

(32).

6. Use an 3 mm hex key wrench to remove the four

screws

(221.

Tap the slide valve plate

(23)

with

a

plastic mallet to loosen

it,

then remove the plate,

gasket (241, slide valve (25) and spring (26) from the

valve block

(32).

7. Slide the spool valve (31) out of the valve block

(32).

Check the quad rings

(29)

carefully and replace, if

necessary.

8.

Clean

all

parts thoroughly and inspect for wear or

damage. If the pilot valve sleeve

(SI

has nicks, burrs

or excessive wear, replace the valve block

(321.

threads inside the pilot

valve

spool

(28)

to remove

Clean the threads of the actuator pin 127) and the

the old thread sealant.

9. Lubricate all parts before reassembling.

10. Slide the pilot valve spool

(28)

into the sleeve

(SI.

the actuator pin (271. Screw the pin into the spool.

Apply

a

drop of Loctitem No.

222

to the threads of

sure

the

spool

moves freely.

Use the pin to move the

spool

back and forth to be

11. Slide the spool valve (31) into the block

so

the flat

section faces the rectangular opening in the block.

12. Grease the spring (26) and place

it

in the valve spool

recess. Position the slide valve (25) over the spring,

so

the spring fits into the spring recess in the bonom

of

the slide valve.

13. Place

a

gasket

(24)

on the slide valve plate (23).

the slots on the edge of the plate face the same way

Place the plate on the valve block (32), making sure

as

the actuator pin (27).

14. Install the screws

(22)

and torque to 3.4-4.5 N.m

(2.53.3 ft-lb).

15. Position the air inlet gasket

(381

and the plate

(37)

on

the valve block. Install the screws

(39)

and torque to

6.8-7.9 N.m (55.8 ft-lb).

16. Install the right and left valve caps 130 and 331 on the

valve block, matching the holes in the caps and the

slide valve plate.

17. Look in the pump housing to check the position of

the diaphragm shaft (11.. Slide the actuator pin (271

so

that

it

will enter the pump housing toward the

small diameter of the shaft to prevent damaging the

shaft. See Detail

B,

Fig 5.

18. Lubricate the outside of the valve caps

(30

and

33)

with light grease. Guide the

air

valve assembly into

the pump housing,

so

the arrow

on

the inlet plate

(37)

faces the arrow on the pump housing

(2).

19. Tap the air inlet plate (37) with

a

plastic mallet to

help align the screw ,holes of the plate and pump

housing. Install a screw (35) and washer

(36)

to

check the alignment; adjust as necessary. Loosely

install a screw and washer in the opposite corner.

Then install the remaining screws and washers. Us-

ing an opposite and alternate pattern, torque the

screws evenly to 6.59.5 Nm (6.2-7 ft-lb).

20. Install the air control valve (41

I,

making sure the ar-

row on the valve body faces the pump.

To

Check the Air Valve Assembly

21. Be sure the air control valve (41)

is

turned

Off

(fully

clockwise), then connect the air supply line.

22.

Open the bleed-type master air valve, then open the

air control valve slowly; the pump should cycle.

23. If the pump does not start, check to be sure

(a)

that

the pin (27) was moved to the small diameter

of

the

shaft, (b) that you installed the air valve assembly

correctly, or (cl that you assembled the air valve

"."..*,..

Loading...

Loading...