307-863

13

TROUBLESHOOTING GUIDE

Pressure

Relief Procedure

To

reduce the risk of serious bodily injury

, including fluid

injection,

splashing in the eyes or on the skin, or injury

from moving parts, always follow this procedure when

you

shut of

f the sprayer

, when checking, adjusting

or

cleaning

the system, and when changing spray tips.

1.

Engage the gun safety latch.

2. T

urn the engine stop lever to OFF

.

3.

Flip the pressure control switch to OFF

.

4. Disengage

the gun safety latch. Hold a metal part

of the gun firmly to the side of a grounded metal

pail,

and trigger the gun.

5.

Engage the gun safety latch.

6. Open the fluid pressure drain valve and leave it

open

until you start the sprayer again.

7.

Disconnect the spark plug.

If you suspect the hose or spray tip is completely

clogged

or that pressure is

not fully relieved after fol

-

lowing

the steps above,

wrap a

rag around the tip re

-

taining

nut or hose end coupling and

VER

Y SLOWL

Y

loosen the part to relieve pressure gradually. Now

clear

the tip or hose.

WARNING

0139

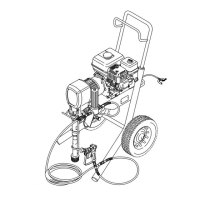

1,5 2 3 4 6

Check everything in the chart before disassembling the sprayer

.

(Continued on page 14)

PROBLEM CAUSE SOLUTION

Engine/sprayer

won’t start

Engine switch not on

T

urn on.

Out of gas

Replenish

Engine oil level low

Try starting engine. If light on rear of engine

glows,

replenish oil.

Spark plug cable disconnected or

spark plug damaged

Connect

cable on top of engine or replace spark

plug.

Water

frozen in pressure control

Return pressure control to authorized Graco

dealer

for repair

.

Engine won’t “pull over”

Oil seepage into combustion

chamber

Remove

spark plug. Pull starter rope 3 or 4 times.

Clean

and replace plug. T

ry to start. Keep spray

-

er

upright to avoid oil seepage.

Engine

operates, but displacement

pump

doesn’t

Pressure control switch turned OFF T

urn on.

Pressure setting too low

Increase pressure.

Displacement pump outlet filter dirty

Clean filter

.

T

ip or tip filter clogged

Clean tip or tip filter

.

Displacement pump rod seized by

dry paint

Service pump. See page 18.

Connecting rod worn or damaged

Replace. See page 20.

Drive housing worn or damaged

Replace. See page 21.

Electrical power not energizing field

Check wiring connections. See page 16.

With pressure control switch ON and pressure

turned to MAXIMUM, use a test light to check

continuity across black and white wires from

pressure

control.

Have pressure control checked by authorized

Graco

dealer

.

Clutch worn or damaged

Service. See page 24.

Pinion assembly worn or damaged Service. See page 22.

Loading...

Loading...