5308-798

Service

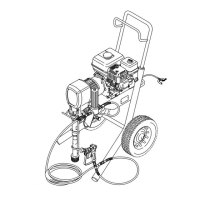

WARNING

COMPONENT RUPTURE HAZARD

Do not clean or wipe the piston valve

threads. Cleaning the piston valve

threads could destroy the special sealing

patch and cause the piston valve to come loose

during operation, causing pump bursting and

possible serious bodily injury.

Fig. 28. Unscrew piston valve from piston rod. Clean

and inspect parts. The piston has a special thread

locking/sealing patch. Do not remove the patch. The

patch allows four disassembly/assembly procedures

before it is necessary to apply Loctite to the threads.

Fig. 28

7576A

Fig. 29. Remove packings and glands from piston rod.

7574B

Fig. 29

Used on

240–291

240–800

&

240–917

Fig. 30. Remove throat packings and glands from cyl-

inder. Discard throat packings and glands.

Fig. 30

7573B

Used on

240–291

240–800

&

240–917

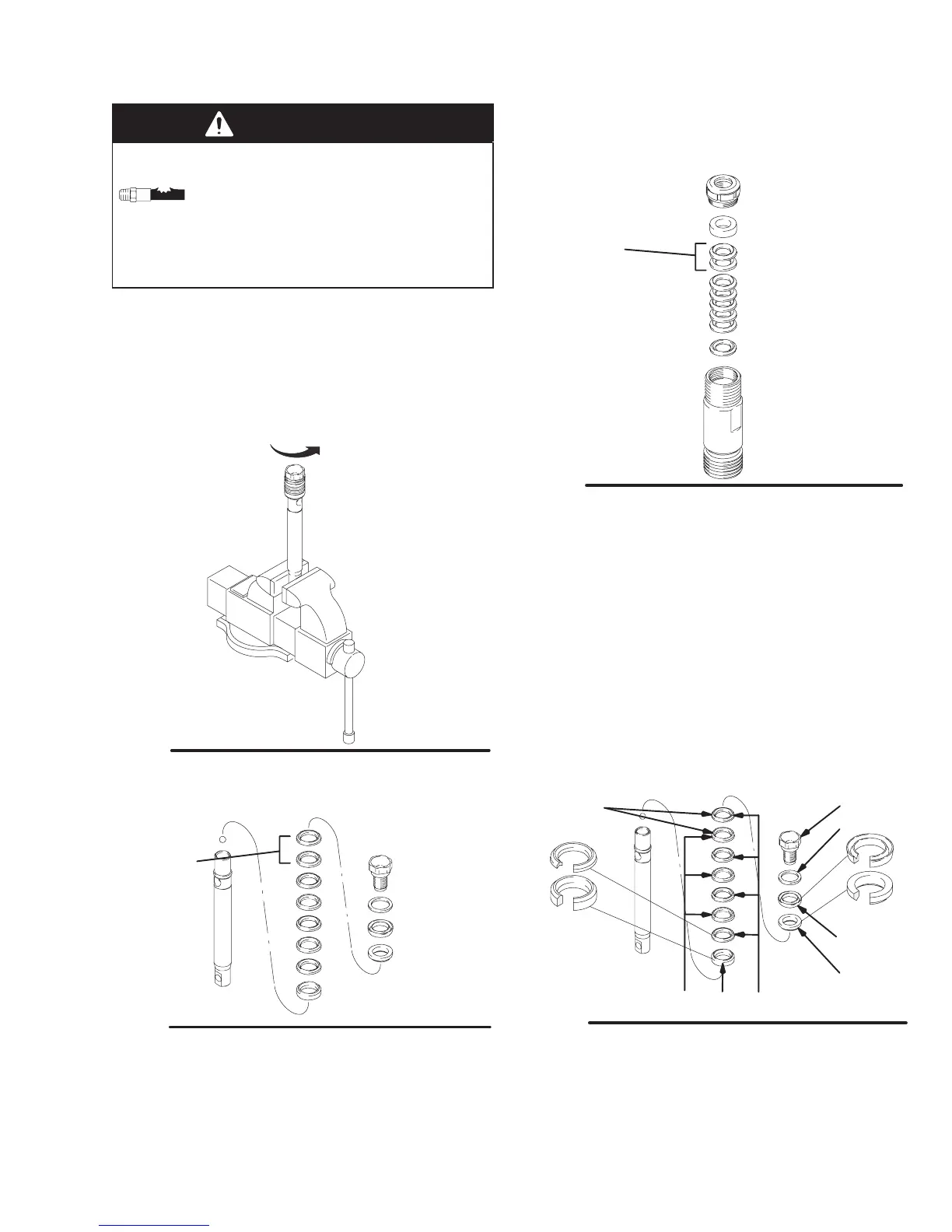

Assembling the pump

Fig. 31. Soak all leather packings in SAE 30W oil for 1

hour minimum prior to assembly. Stack male gland

(219) on piston rod. Alternately stack UHMWPE (208)

and leather (218) packings (note orientation) on piston

rod. Install female gland (217). Install backup washer

(216) and u-cup (209) (note orientation) on piston

valve (210). The special sealing patch on piston valve

threads is good for four repackings. Use Loctite on

piston valve threads after four repackings.

7574B

Fig. 31

216

218

209

208219

217

210

Used on

240–291

240–800

&

240–917

Loading...

Loading...