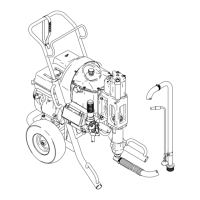

ELECTRIC MOTOR REPLACEMENT

Fig

12

75

26

46

44

16

66

47

74

34

65

82

17

9

4

55

63

5

NOTE:

Refer to Fig 12 for this procedure.

If the electric motor (63) won’t run and the circuit, on/off

switch and fuse are good, relieve pressure, unplug the

sprayer

and proceed as follows.

1. Remove the shield (1 19), the four screws (9) and

washers (17) and the upper fan guard (82). Loosen

the

fan blade setscrew and remove the fan (26).

2. Remove the switch box cover (34) and disconnect

the power cord wires. Do not to scratch the smooth

mating surfaces of the switch box (65) and cover

(34).

3. Drive out the two spring pins (16) and then pull out

the handle (75). Hook the switch box conduit with a

hoist

and lift the unit about 6 in. (150 mm) of

f the floor

.

Pull the cart frame (74) down out of the support

mounting

(44) and move it out of the way

.

4.

Remove the eight screws (4) and washers (5) hold

-

ing the reservoir mounting (44). Raise the unit high

enough

for the

reservoir (66) to clear

. Pull the reser

-

voir

down of

f the unit and

pour out the hydraulic fluid.

5. Carefully

lower the unit and tilt it back until the arms

of

the support mounting (44) are resting on the floor

.

6. Put the cart handle (75) through the arms. Hold the

hook

on the switch box (65) as you lower the unit to

make

sure it doesn’t slip of

f.

7. Remove the four electric motor mounting screws (7

–

see page 20), hold the motor

(63) by the shaft and

switch

box (65), and then rock it from side to side to

free

it from the support mounting. Carefully pull it out

of

the cooling coils (46).

8. Screw

the switch box (65) and

nipple (1

1 – see page

20)

out of the motor

. T

ake the coupling off the motor

shaft

and install it on the new

motor

. When installing

the nipple and switch box, engage the threads at

least

five full turns.

9. Carefully slide the new motor through the cooling

coils (46), forcing it into the support mounting, and

tightly

install the mounting screws.

10. Set the gap between the two coupling halves at

0.31 in. (0.8 mm), and then tighten the coupling

setscrew

securely. See Fig 13, page 19.

11. Clean

the reservoir (66) of sediment and reassemble

the unit using a new gasket (47). Fill the hydraulic

fluid

reservoir through the fill hole filter (55).

Loading...

Loading...