Bearing

Housing and Connecting Rod

WARNING

INJECTION

HAZARD

T

o reduce the risk of serious injury

,

whenever you are instructed to relieve

pressure, follow the

Pressure Relief

Procedure

on page 8.

NOTE:

Stop the sprayer at the bottom of its stroke to

get the crank (H) in its lowest position.T

o lower the

crank manually

, rotate the blades of the motor fan with

a screwdriver

.

1.

Remove pump. See page 16.

2.

Remove front cover (31). Remove bearing housing

screws (33). See Fig. 18 and part list.

3. T

ap lower rear of bearing housing (27) with plastic

mallet to loosen it from drive housing (18). Pull

bearing housing and connecting rod (29) straight

of

f drive housing.

4.

Inspect crank (H) for excessive wear and replace

parts as needed.

5.

Evenly lubricate inside of bronze bearing (K) with

motor oil. Liberally pack roller bearing (J) with

bearing grease.

6.

Assemble connecting rod (29) and bearing housing

(27).

7.

Clean mating surfaces of bearing and drive hous

-

ings.

8.

Align connecting rod with crank (H) and align

locating pins in drive housing with holes in bearing

housing (27). Push bearing housing onto drive

housing or tap into place with plastic mallet.

9.

Install bearing housing screws (33). T

orque evenly

to 34 N.m (300 in–lb).

10.

Reinstall all parts. See page 16 to install pump.

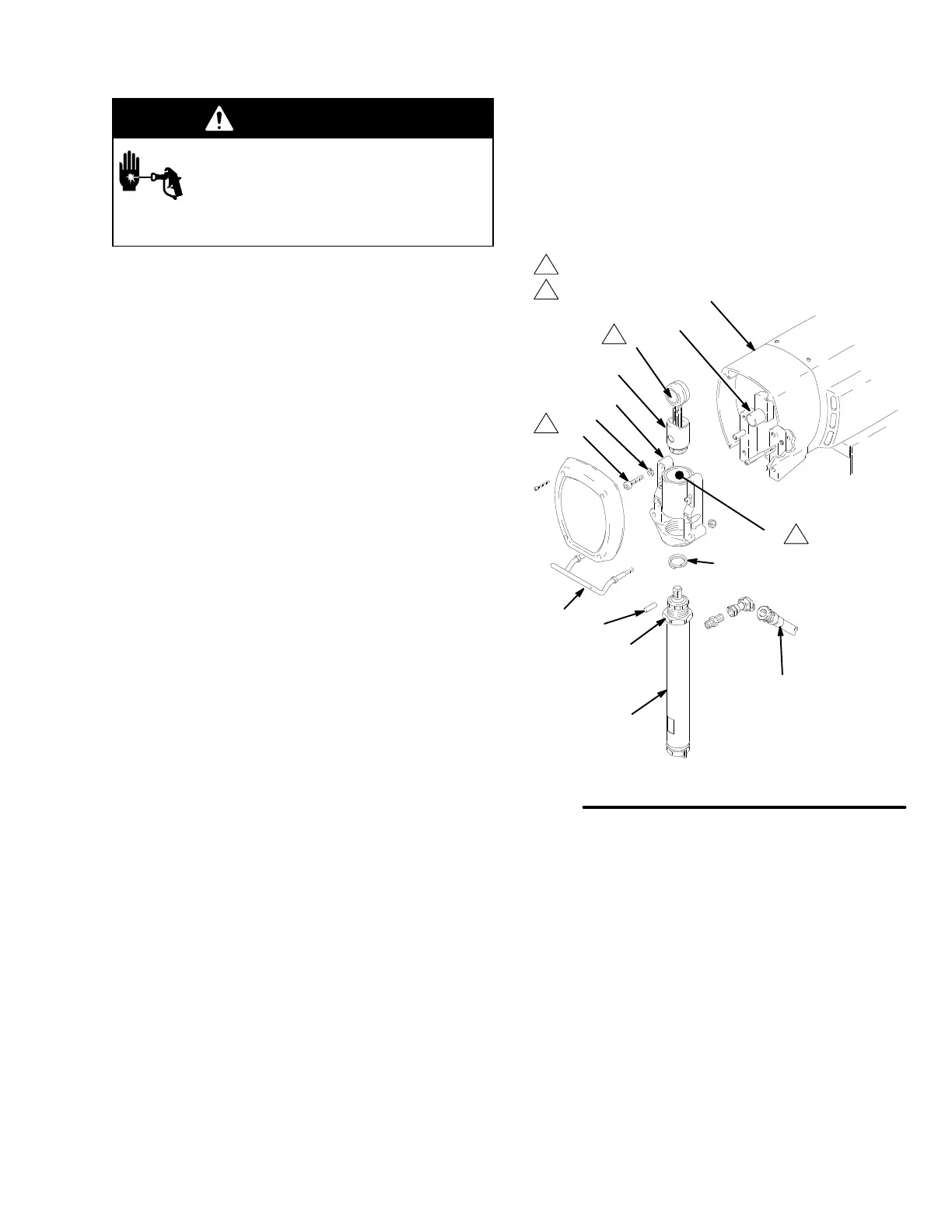

04351A

Fig 18

1

2

49

27

29

J

H

18

K

33

132

20

35

38

39

1

31

Torque

to 34 n.m (300 in-lb)

Lubricate

2

2

Loading...

Loading...