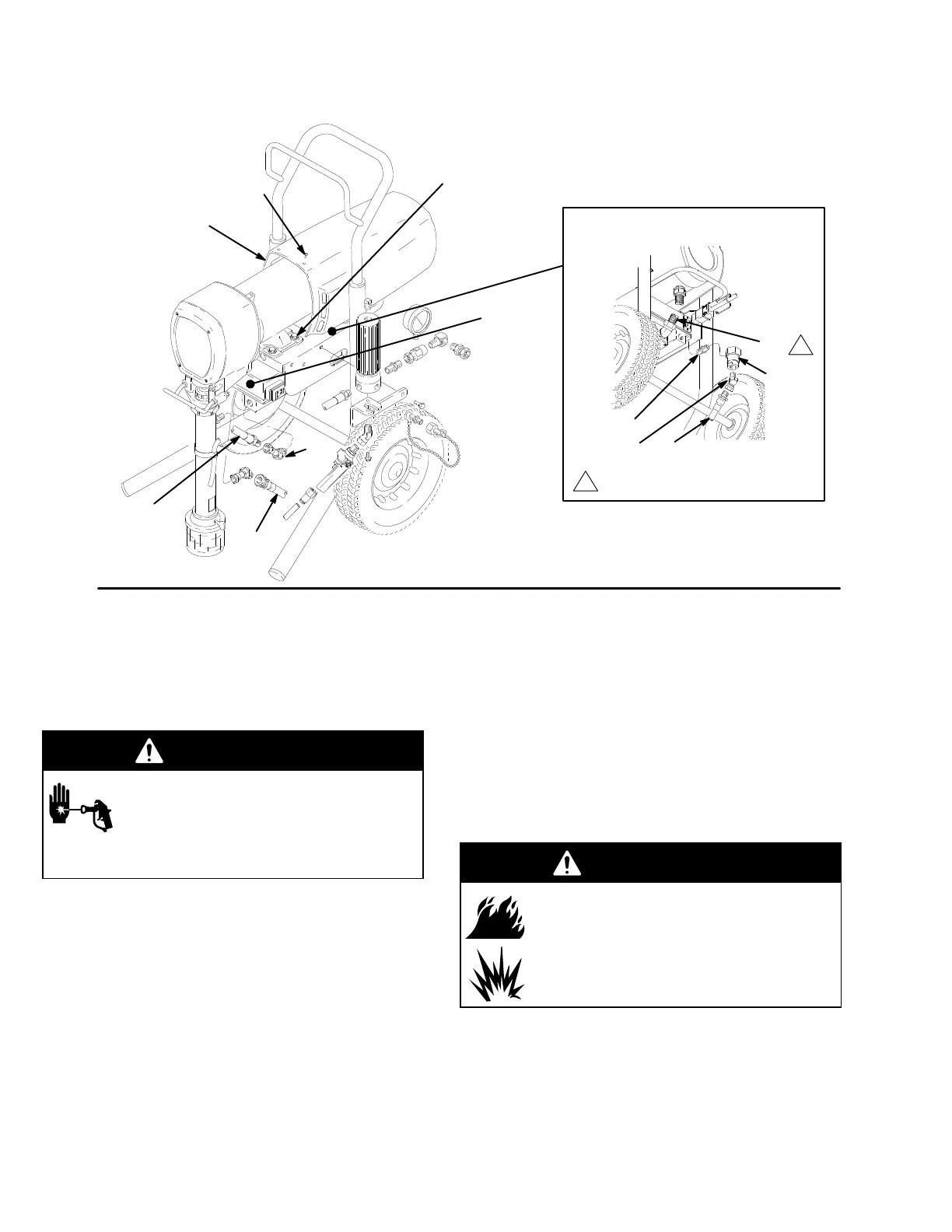

Pressure

Control

7093A

Fig

15

131

132

22

64

131

42

134

06964

59

37

130

14

1 Seals

(93) located inside conduit (22)

132

1

Pressure

Control Repair

General Repair and Replacement

WARNING

INJECTION

HAZARD

T

o reduce the risk of serious injury

,

whenever you are instructed to relieve

pressure, follow the

Pressure Relief

Procedure

on page 8.

1.

Relieve pressure.

2.

Remove power cord (23) and plug retainer (23a)

by removing screws (230) and washers (229).

3.

Remove screws (213) and lockwashers (214).

Carefully remove control housing (202) from

control motor board (201) so internal wiring is not

damaged. Lay housing on side next to control

motor board. See Fig. 16 and parts list.

4.

Remove and replace only those components and

wires necessary for repair

. Make a diagram show

-

ing wire hook–ups for items removed to insure

correct wiring when reinstalling. See Fig. 17 for

wiring information.

5.

Install control housing (202) to motor control

board (201) using screws (213) and

lockwashers (214).

Pressure Control Transducer and O–Ring

Replacement

WARNING

FIRE

AND EXPLOSION HAZARD

Proper O–ring replacement is essential

to reduce the risk of fire or explosion

which can result in serious injury and

property damage. Also read

FIRE OR

EXPLOSION HAZARD

on page 2.

NOTE:

Do not replace o–ring unless damaged or if

leakage is seen around weep hole, o–ring or

transducer.

1.

See Fig. 16 and pressure control part list. Disas

-

semble pressure control as in steps 1 through 4 on

page 20 and remove old transducer (219) and, if

necessary

, old o–ring (220).

Loading...

Loading...