Operation

Pressure Relief Procedure

WARNING

PRESSURIZED

EQUIPMENT HAZARD

The system pressure must be manually

relieved to prevent the system from

starting or spraying accidentally

. To

reduce the risk of an injury from accidental spray

from the gun, splashing fluid, or moving parts,

follow the

Pressure Relief Procedure

whenever

you:

D

are instructed to relieve the pressure,

D

stop spraying,

D

check or service any of the system equipment,

D

or install or clean the spray nozzle.

1.

Engage gun safety latch.

2. T

urn ON/OFF switch to OFF

.

3.

Unplug power cord.

4.

Disengage gun safety latch. Hold metal part of gun

against grounded metal pail and trigger gun into

pail to relieve pressure.

5.

Engage gun safety latch.

6.

Open any fluid drain valves in system. Leave drain

valve open until ready to dispense again.

Cleaning a Clogged Tip

WARNING

INJECTION

HAZARD

T

o reduce the risk of serious injury

,

whenever you are instructed to relieve

pressure, follow the

Pressure Relief

Procedure.

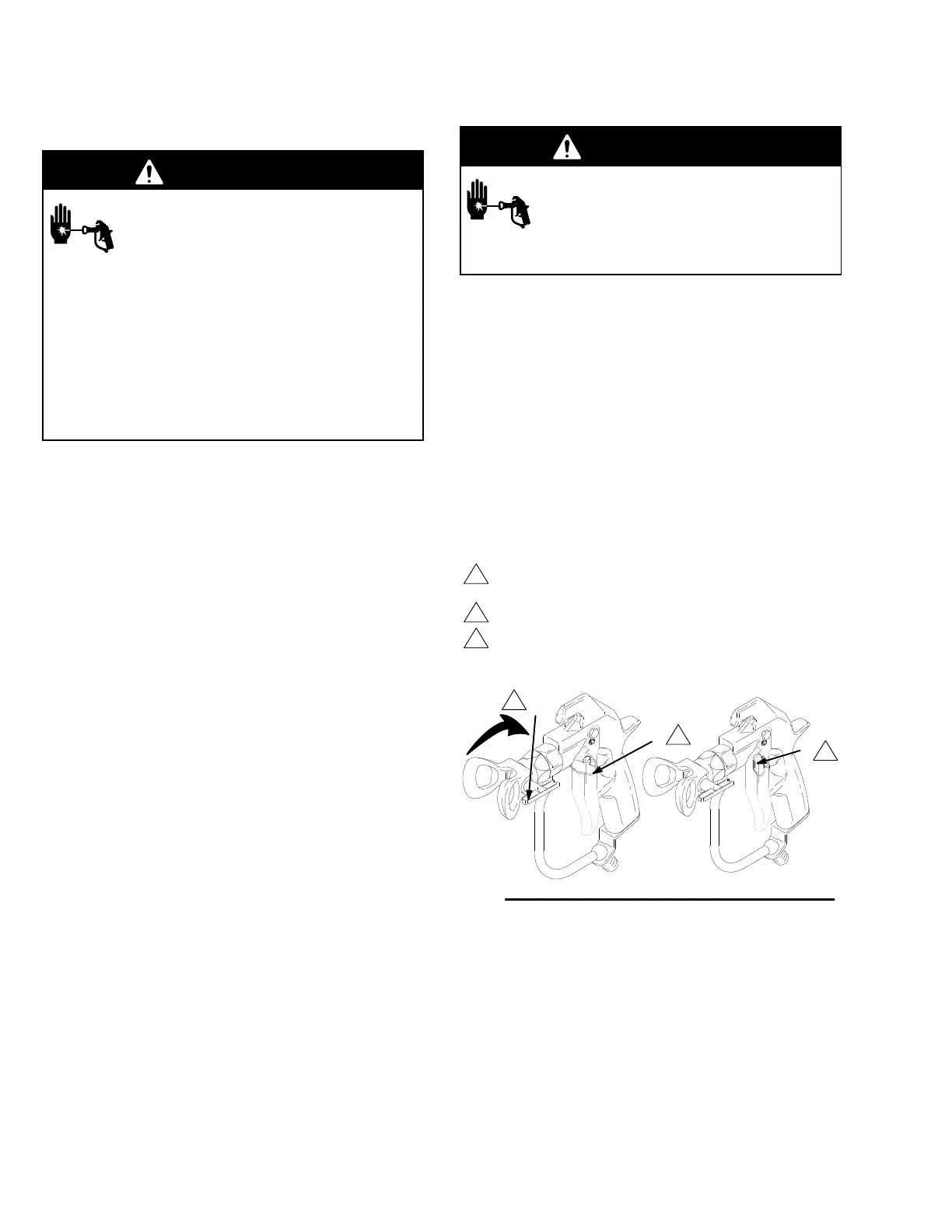

1.

If spray tip clogs, release gun trigger,

engage gun safety latch (B), and rotate RAC IV

handle (A) 180

_

. See Fig 4.

2.

Disengage gun safety latch (C) and trigger gun

into waste container

. Engage gun safety latch

again.

3.

Return tip handle to original position,

disengage gun safety latch, and resume spraying.

4.

If tip is still clogged, engage gun safety latch, shut

of

f and unplug sprayer

, and open pressure drain

valve to relieve pressure. Remove tip and soak it

in solvent. Do not scrape or chip of

f debris which

could damage tip.

03966

Fig 4

A

B

The

tip handle (A) is shown in spraying position.

Rotate the tip handle 180

_

in direction

of the arrow for clearing a clog.

C

Engaged.

Disengaged.

Loading...

Loading...