Typical Installation

3A7004B 11

NOTE: High velocity air exhaust will decrease the oper-

ating efficiency of the electrostatic system. Air exhaust

velocity of 100 ft/min (31 linear meters/minute) should

be sufficient.

Components

See FIG. 1. Components vary by package ordered.

See table on page 24. Your package may include:

• A bleed-type master air valve (U) is required in your

system to relieve air trapped between it and the air

motor and gun when the valve is closed. Do not

block access to the valve.

• The pump air regulator (X) controls pump speed

and outlet pressure by adjusting the air pressure to

the pump.

• The air relief valve (not shown) opens automatically

to prevent overpressurization of the pump.

• The gun air regulator (T) adjusts the air pressure to

the electrostatic spray gun (H).

• The electrostatic air spray gun (H) dispenses the

fluid.

• The suction hose (N) with strainer (P) allows the

pump to draw fluid from a 5 gallon (19 liter) pail.

• A fluid filter (F) with a 60 mesh (250 micron) stain-

less steel element filters particles from fluid as it

leaves the pump.

• A fluid drain valve (AC) relieves fluid pressure in the

hose and gun.

• DataTrak (V) provides pump diagnostics and mate-

rial usage information. See page 17.

Air and Fluid Hoses

• The gray hose (AA) provides the gun air supply.

• The blue hose (Z) provides the gun fluid supply.

Grounding

The following are minimum grounding requirements for

a basic electrostatic system. Your system may include

other equipment or objects which must be grounded.

Check your local electrical code for detailed grounding

instructions. Your system must be connected to a true

earth ground.

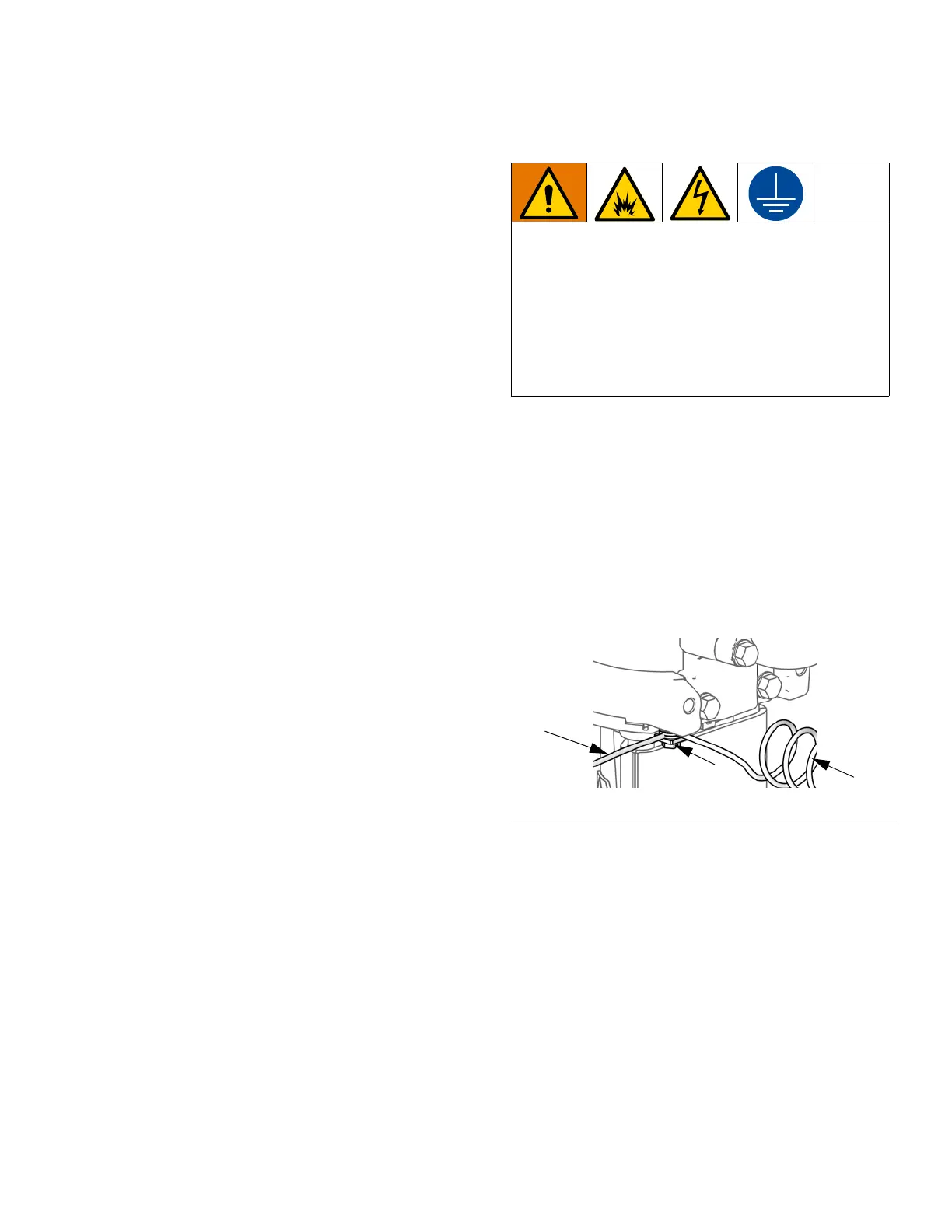

Pump: Verify that the ground screw (GS) is attached

and tightened securely to the air motor. Connect the

other end of the ground wire (R) to a true earth ground.

Electrostatic Spray Gun: Use only the Graco Electri-

cally Conductive Air Supply Hose (supplied). Connect

the Gun Grounding Wire (AC) to the ground screw (GS)

on the air motor.

Air compressor: follow manufacturer’s recommenda-

tions.

All air and fluid lines must be properly grounded. Use

only grounded hoses with a maximum of 500 feet

(150m) combined hose length to ensure grounding con-

tinuity.

Object being sprayed: keep the workpiece hangers

clean and grounded at all times. Follow local code.

When operating the electrostatic gun, any

ungrounded objects in the spray area (people,

containers, tools, etc.) can become electrically

charged.The equipment must be grounded to reduce

the risk of static sparking and electric shock. Electric

or static sparking can cause fumes to ignite or

explode. Improper grounding can cause electric

shock. Grounding provides an escape wire for the

electric current.

F

IG. 2. Ground Screw and Wire

Loading...

Loading...