22

The air pressure in the vessel must be

checked annually.

The central heating system volume,

using the expansion vessel as supplied,

must not exceed the recommended

value. Refer to Section 2.2. If the system

volume is greater, an extra expansion

vessel (complying with BS 4841) must be

fitted as close as possible to the central

heating return connection on the boiler.

The charge pressure of the extra vessel

must be the same as the vessel fitted in

the boiler.

Refer to either BS 7074:1:1989 or The

Domestic Heating Design Guide for

the required total expansion vessel

volume for the system concerned.

The air charge pressure may be checked

using a tyre pressure gauge on the

expansion vessel Schraeder valve. The

vessel may be re-pressurised using a

suitable pump. When checking the air

pressure the water in the heating system

must be cold and the system pressure

reduced to zero.

Sealed Systems

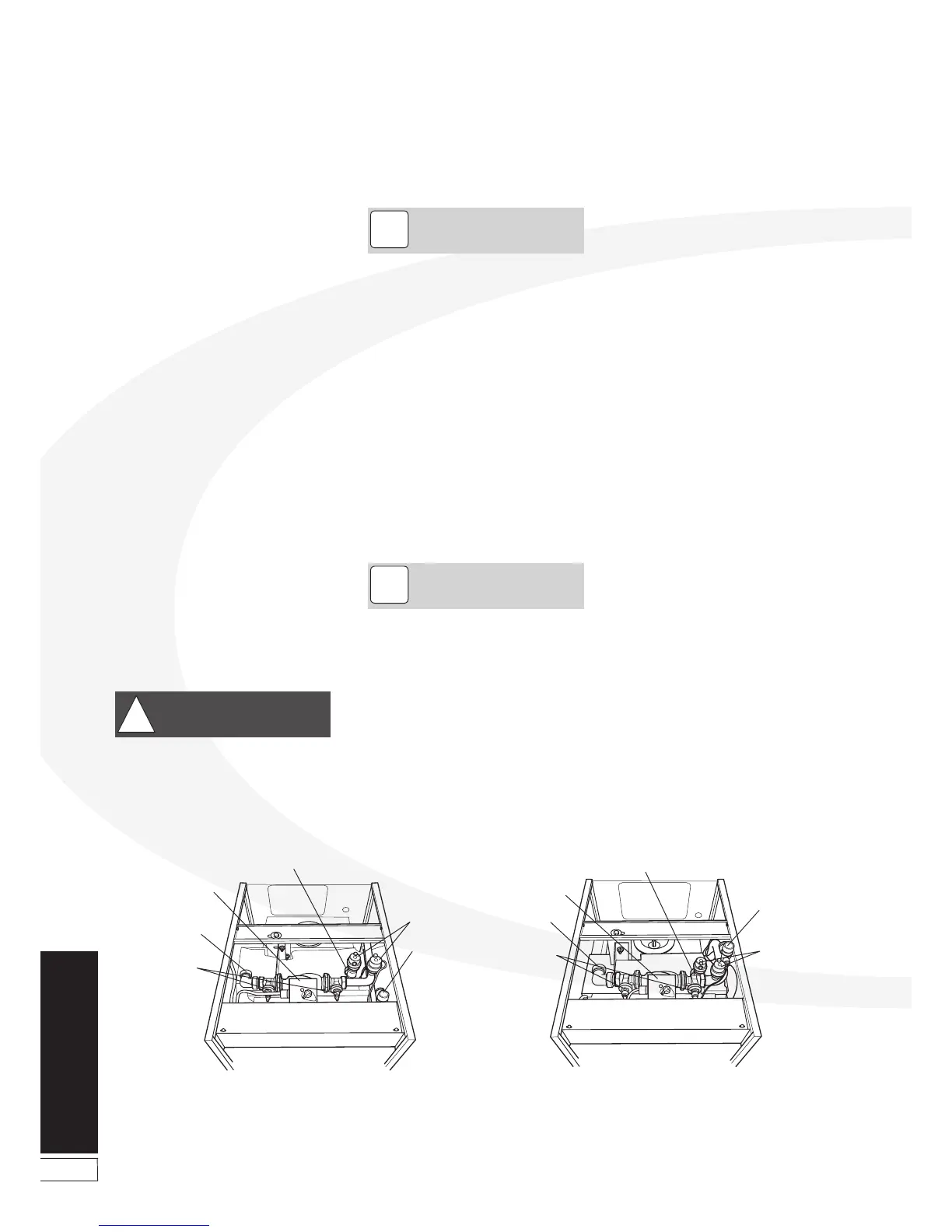

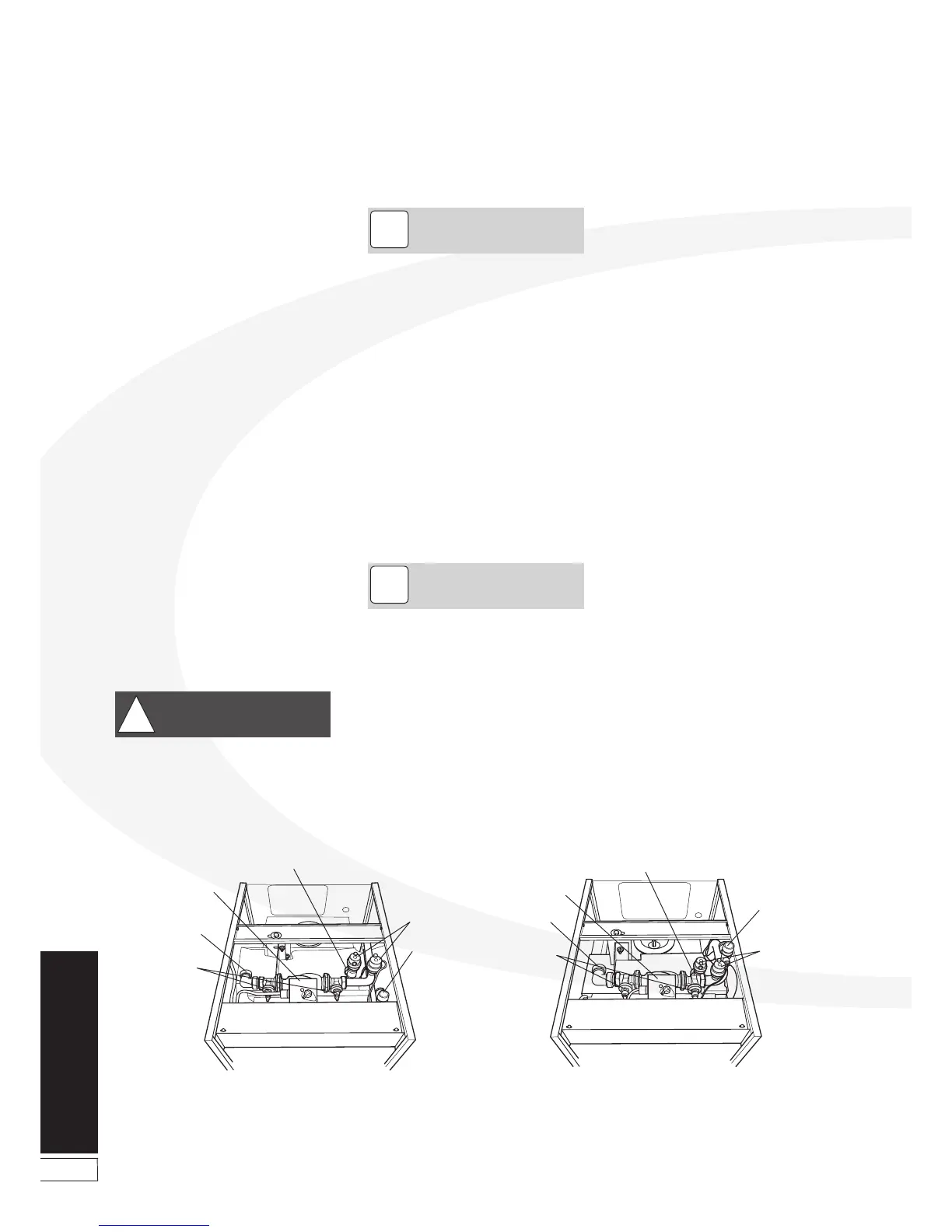

7.2 System Models

All System models have the following

sealed system components factory fitted

(refer to Figure 7-3):-

• A diaphragm expansion vessel

complying with BS 4814, pre-charged

at 1.0 bar. Refer to Section 2.2.

• System pressure gauge, with an

operating range of 1 to 4 bar.

• Pressure relief safety valve complying

with BS 6759 and set to operate at

2.5 bar.

• Automatic air vent, fitted to the flow

pipe of the boiler, ensures the boiler

is vented.

• Filling loop. This must be isolated and

disconnected after filling the system.

Refer to Section 2.2 for system volumes

and BS 7074: for further guidance and

for further details of the expansion

vessel.

The expansion vessel fitted, is supplied

with a charge pressure of 1.0 bar

(equivalent to a maximum static head of

10.2 metres). The charge pressure must

not be less than the actual static head at

the point of connection.

Do not pressurise the vessel above

1.5 bar.

Figure 7-3: Sealed system components

CAUTION

!

7.3 Fill the Sealed System

Automatic air vent(s) are fitted to the top

of the boiler (see Figure 7-3). Check that

the small cap on the top of each air vent

is screwed on fully, then unscrew it one

complete turn - the cap remains in this

position from now on.

The procedure for filling the sealed

system is as follows:

1. Only ever fill or add water to the

system when it is cold and the boiler

is off. Do not overfill.

2. Ensure that the flexible filling loop

supplied with the boiler is connected

and that the double check shut off

valve connecting it to the water supply

is closed.

A valve is open when the operating

lever is in line with the valve, and closed

when it is at right angles to it.

3. Open the fill point valve.

4. Gradually open the double check valve

from the water supply until water is

heard to flow.

5. When the white needle of the pressure

gauge is between 0.5 and 1.0 bar, close

the valve.

6. Vent each radiator in turn, starting

with the lowest one in the system, to

remove air.

NOTE

!

NOTE

!

Loading...

Loading...