Page 18

to the right or to the front of the boiler to avoid clashing with

the fl ue.

A 28mm compression fi tting is provided for making the connection

to the open end of the bent fl ow pipe.

The fl ow pipe from the boiler will need to be vented as it is the

highest point on the primary heat exchanger.

! NOTE !

The pipe to be fi tted into the compression fi tting provided

should be cut using a pipe slicer or pipe cutter, to leave the

end with a slight radius and free from any burrs or sharp

edges. It must NOT be cut using a hacksaw.

RETURN CONNECTION

A 1” BSP socket is provided for the boiler return connection. This

is located on the top of the boiler towards the front on the right

hand side. Refer to Figure 5-2.

The return pipe to the boiler will also need to be vented as it is the

highest point on the secondary heat exchanger.

5.4 46/70 MODELS

FLOW CONNECTION

A 1¼ BSP socket is provided for the boiler fl ow connection. This

is located in the right hand side of the boiler. Refer to Figure 5-4.

The fl ow pipe from the boiler will need to be vented as it is the

highest point on the primary heat exchanger.

Dual stat phials

located in flow

connection at boiler

Figure 5-4: 46/58 and 58/70 models - dual stat, dual stat phials,

fl ow and return connections

RETURN CONNECTION

A second 1¼ BSP socket is provided for the boiler return

connection. This is located on the top of the boiler towards the

front on the right hand side. Refer to Figure 5-4.

The return pipe to the boiler will also need to be vented as it is the

highest point on the secondary heat exchanger.

5.5 FITTING THE DUAL THERMOSTAT

Refer to Section 8 for the dual thermostat electrical connection

details.

The dual thermostat is supplied factory fi tted on the 46/70 and

58/70 Boiler House models. Refer to Figure 5-4.

On all other models the dual thermostat is supplied on a mounting

bracket for fi tting on to the boiler casing by the installer on site. It

is to be located on the top of the boiler, at the front, towards the

right hand side. Refer to Figures 5-1 and 5-2.

To fi t the dual thermostat/mounting bracket:

1. Unscrew and remove the two fi xing screws from the top of

the boiler casing.

2. Position the dual thermostat/mounting bracket such that the

two holes in the fl ange align with the two fi xing holes in the

top of the boiler casing.

3. Secure the dual thermostat/mounting bracket using the two

fi xing screws previously removed.

VORTEX 15/26KW, EUROFLAME 15/26 & 26/36KW

MODELS

To fi t the dual thermostat capillary phials into their pockets on the

boiler:

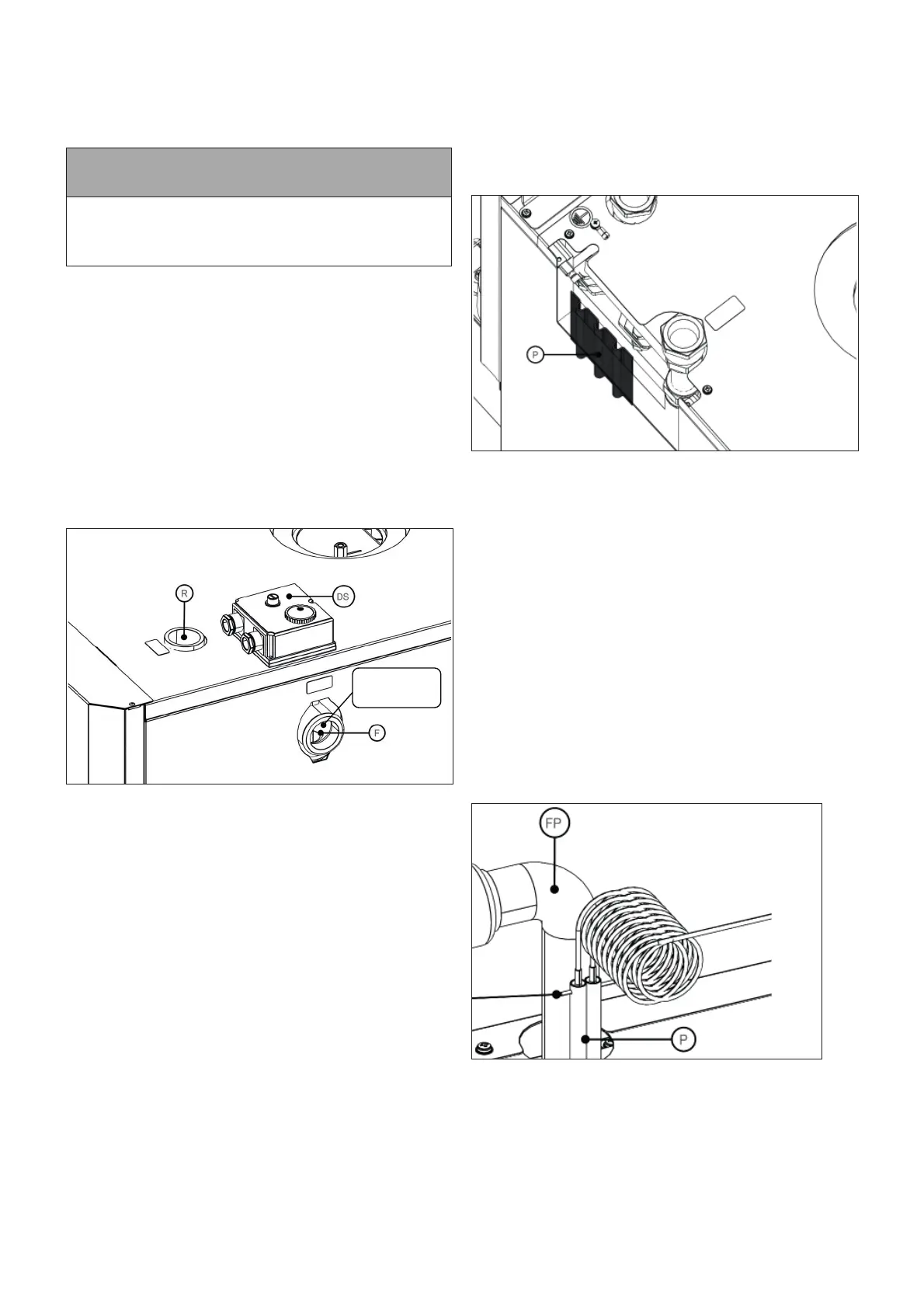

1. Remove the cover plate located at the top of the boiler right

hand side panel.

To do this, unscrew and remove the two screws from the top

fl ange of the cover plate and remove it from the boiler. Refer

to Figure 5-5.

Figure 5-5: Vortex 15/26, Eurofl ame 15/26 & 26/36 model - cover

plate (removed) and dual stat pockets

2. Unwind the thermostat capillaries taking care not to kink or

break them.

3. Locate the two capillary phials in the two pockets on the side

of the boiler, ensuring that the capillaries pass through the

small cut-out in the top casing panel.

4. Refi t the cover plate and secure in position using the two

fi xing screws previously removed.

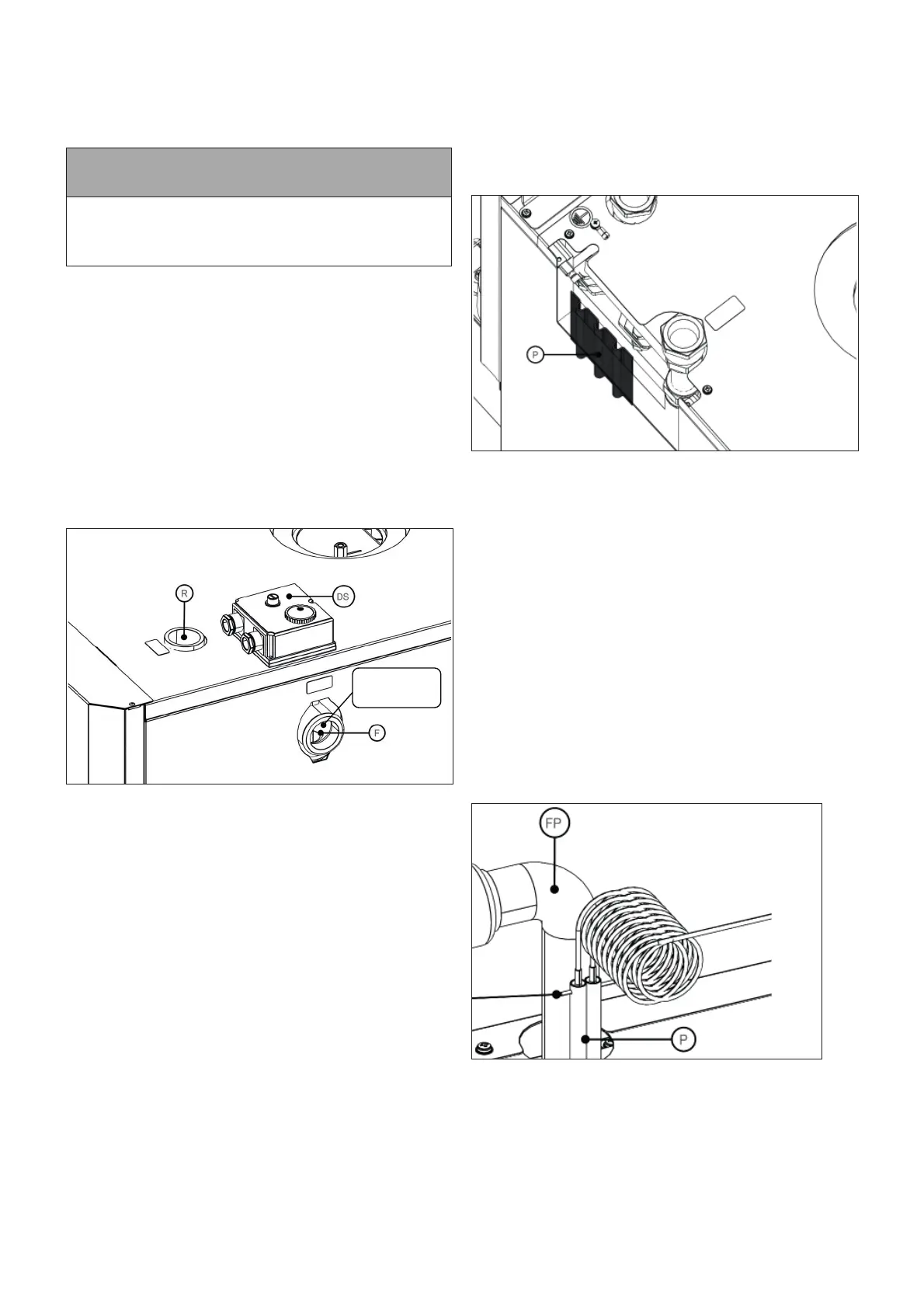

26/36 & 36/46KW MODELS

On this model the two pockets for the dual thermostat capillary

phials are located on the bent fl ow pipe fi tted into the boiler fl ow

connection. Refer to Section 5.3.

1. Unwind the thermostat capillaries taking care not to kink or

break them.

2. Locate the two capillary phials in the two pockets on the side

of the fl ow pipe.

3. Secure both phials in place by fi tting the split pin provided

through the small holes at the top of the phial pockets. Refer

to Figure 5-6.

Figure 5-6: 26/36 & 36/46kW model - dual stat phials fi tted in

pockets

Section 5: Pipe Connections

Loading...

Loading...