Page 39Section 10: Commissioning

1

2

4mm

+

0

3mm

0

-

5.75mm

0.2

0.5

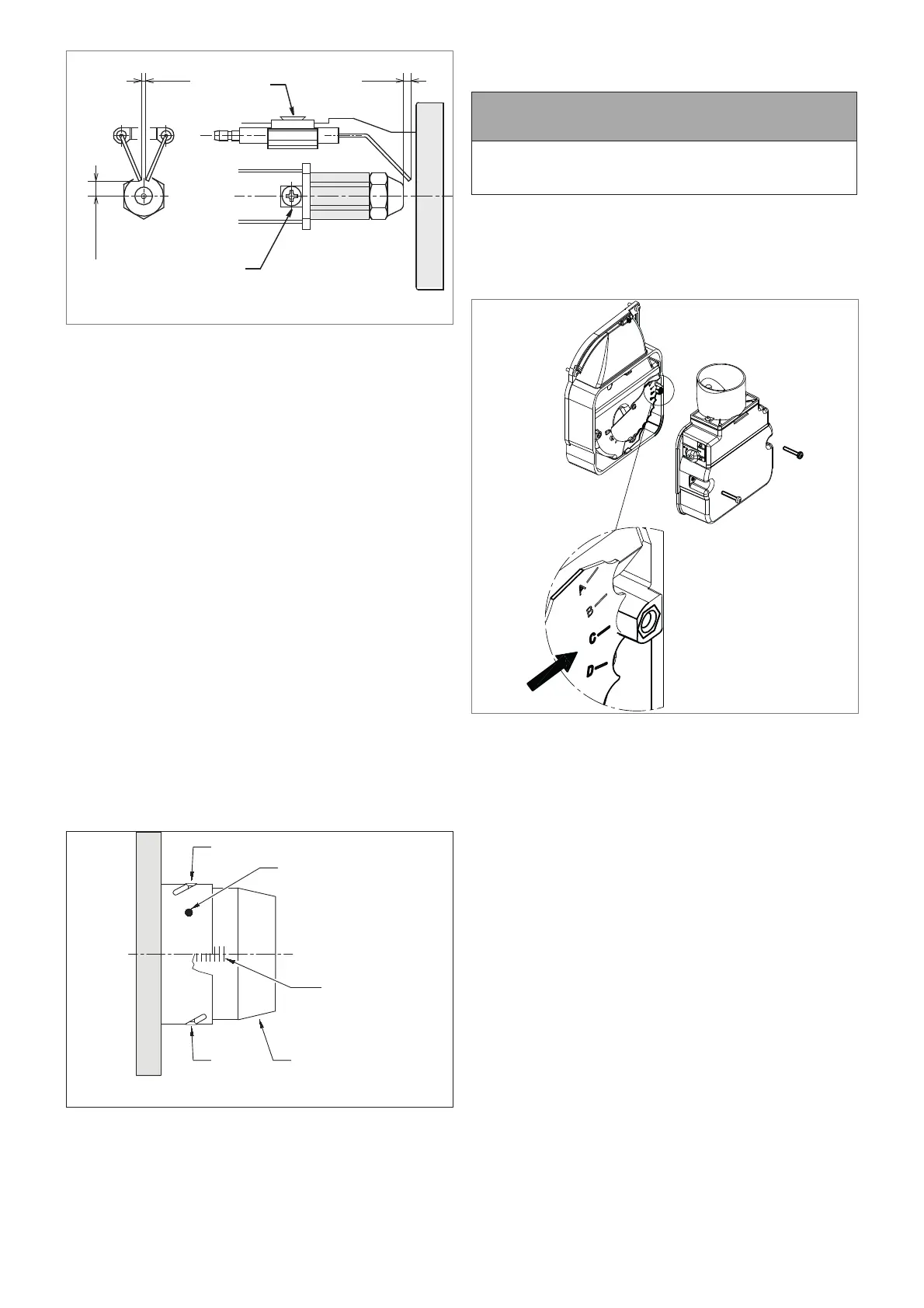

Figure 10-9: Ignition electrode settings

11. Check/adjust the electrode assembly to give the correct gap

(4mm) between the nozzle and electrodes. Refer to Figure

10-9.

• To adjust the electrode position:

- Loosen the electrode clamp screw.

- Slide the electrode assembly to give the correct gap

of 4mm.

- Tighten the electrode clamp screw.

12. Re-fi t the burner head. Refer to Figure 10-8.

• Locate the head fi xing screws in the countersunk slots in

the burner collar.

• Tighten the two screws (3) to secure the head (2) in

position on the burner.

13. Check the combustion head setting.

• The correct head setting depends on the required output

of the boiler. Refer to Table 2-2

• This should be set to ‘0’ in all cases except when the

58/70 is set to maximum (70kw) output.

• In this case the head is set to ‘4’ (i.e. on the 4th line).

Refer to Figure 10-10.

14. To adjust the head setting (if required):

• Loosen the two screws in the curved slots in outer ring

of the head (NOT the two head fi xing screws). Refer to

Figure 10-10.

• Rotate the end of the burner head until either ‘0’ or the

2nd line, as required.

• Tighten the two screws to fi x the head in the required

position.

0

Shutter

Blast tube

Screw

Slotted ring

Screw

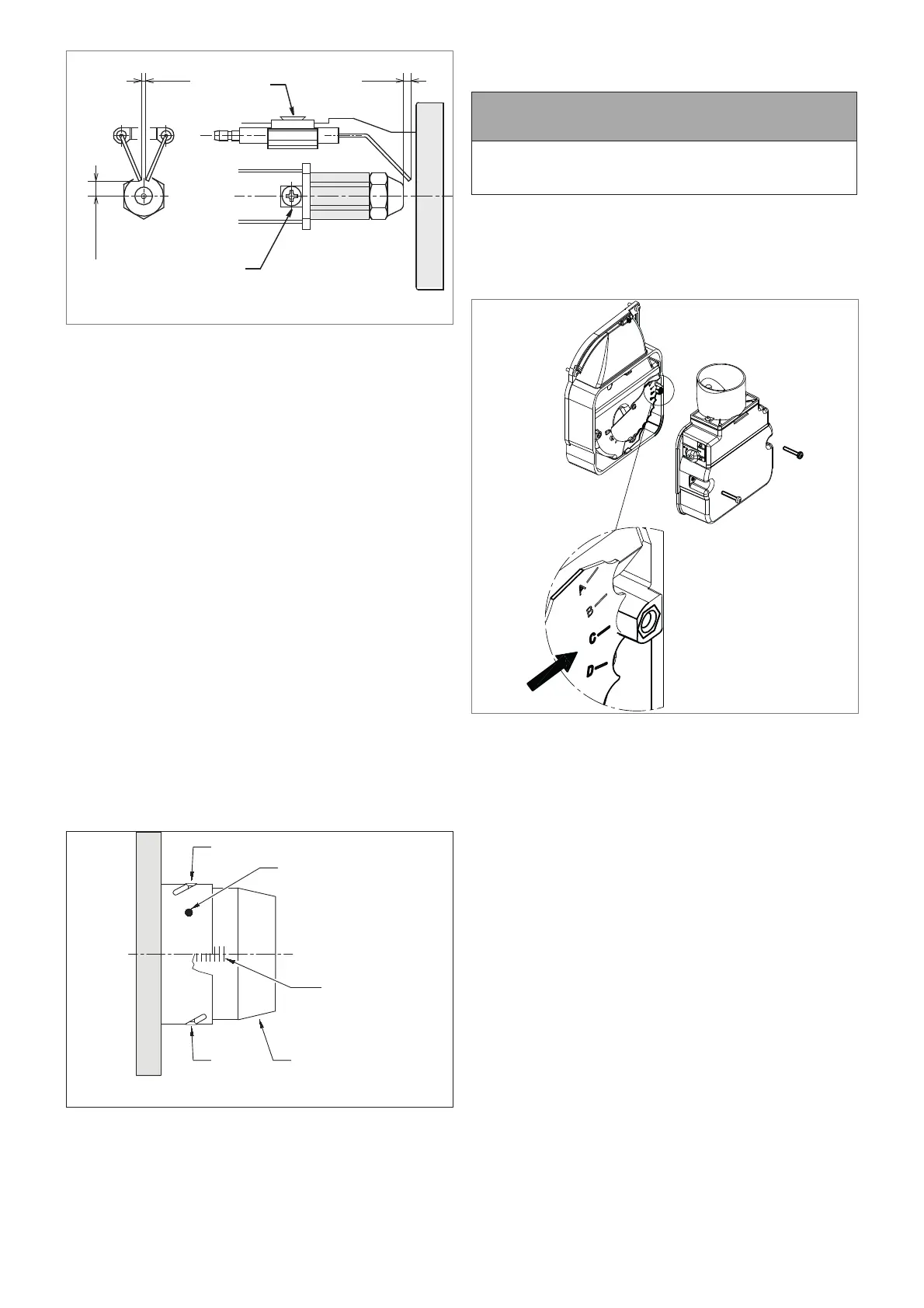

Figure 10-10: Riello RDB 3.2 combustion head adjustment

10.4 AIR ADJUSTER DISC:

15/21 AND 21/26 MODELS ONLY

! NOTE !

If the 15/26 model is to be set to 26kW, the air adjuster disc

is not required. It should be removed from the burner and

discarded.

The Riello RDB 2.2 BX burner fi tted to these boilers incorporates

a secondary air adjustment.

This is an air adjuster disc located on the fan housing (inside the

air inlet housing).

It is essential, for correct operation of the burner, that this internal

air adjuster disc is correctly set. Refer to Figure 10-11.

Figure 10-11: Air adjuster disc

To access the air adjuster disc:

1. Ensure the boiler is isolated from the electrical supply.

2. Remove the burner fi xing nut (located at the top of the

mounting fl ange) and withdraw the burner from the boiler.

3. Undo the two screws and remove the air inlet cover from the

side of the burner.

4. The air adjuster disc is mounted on the fan housing. Refer to

Figure 10-11.

5. Check that this disc is correctly set for the factory set output

of the boiler, i.e. with the correct cut-out mark located against

the moulded boss on the fan housing. Refer to Table 2-2 for

correct disc settings. If the disc is not correctly set it MUST

be re-positioned. Refer to step 7 below.

6. If the burner is to be set to a di erent output than the factory

setting, the air adjuster disc MUST be set to the required

setting for that output. Refer to Table 2-2 for correct disc

settings.

7. The air adjuster disc is re-positioned as follows:

• Remove the screw from the centre of the air adjuster

disc.

• Re-position the disc so that the correct cut-out is located

against the moulded boss on the fan housing.

• Replace the screw in the centre of the air shutter disc

and tighten.

8. If the 15/26 model is to be set to 26kW, the air adjuster disc

is not required. It should be removed from the burner and

discarded.

9. Re-fi t the air inlet cover to the side of the burner and secure

in place using the two screws.

Loading...

Loading...