Section 3: Oil Storage and Supply SystemPage 12

If a two-pipe system is to be used, the following additional items

will be required:

• Flexible fuel hose 3/8 male x ¼ female, 630 mm long (product

code: 20022601)

• 3/8x ¼” BSP adaptor (product code: 3005720)

These are available to purchase from Grant Ireland.

3.1.5 SINGLE PIPE (SUCTION) SYSTEM WITH

DEAERATOR - (REFER TO FIGURE 3-3)

If the storage tank outlet is below the level of the burner oil pump,

an alternative to the two pipe (sub gravity) system is the single

pipe (suction) system using a deaerator, e.g. a ‘Tiger Loop’

device.

The deaerator creates a loop with the burner oil pump, with the oil

being circulated through the pump out to the deaerator and back

to the pump. Any air in the single pipe lift from the tank is removed

from the oil, collected in the deaerator and then discharged to

outside.

! WARNING !

To prevent any fuel vapour being discharged within

the building, the deaerator must be fi tted outside, in

accordance with BS 5410-1, unless it is specifi cally

designed to be installed inside.

The de-aerator must be mounted vertically at the same level as

(or above) the burner oil pump. Refer to Figure 3-3.

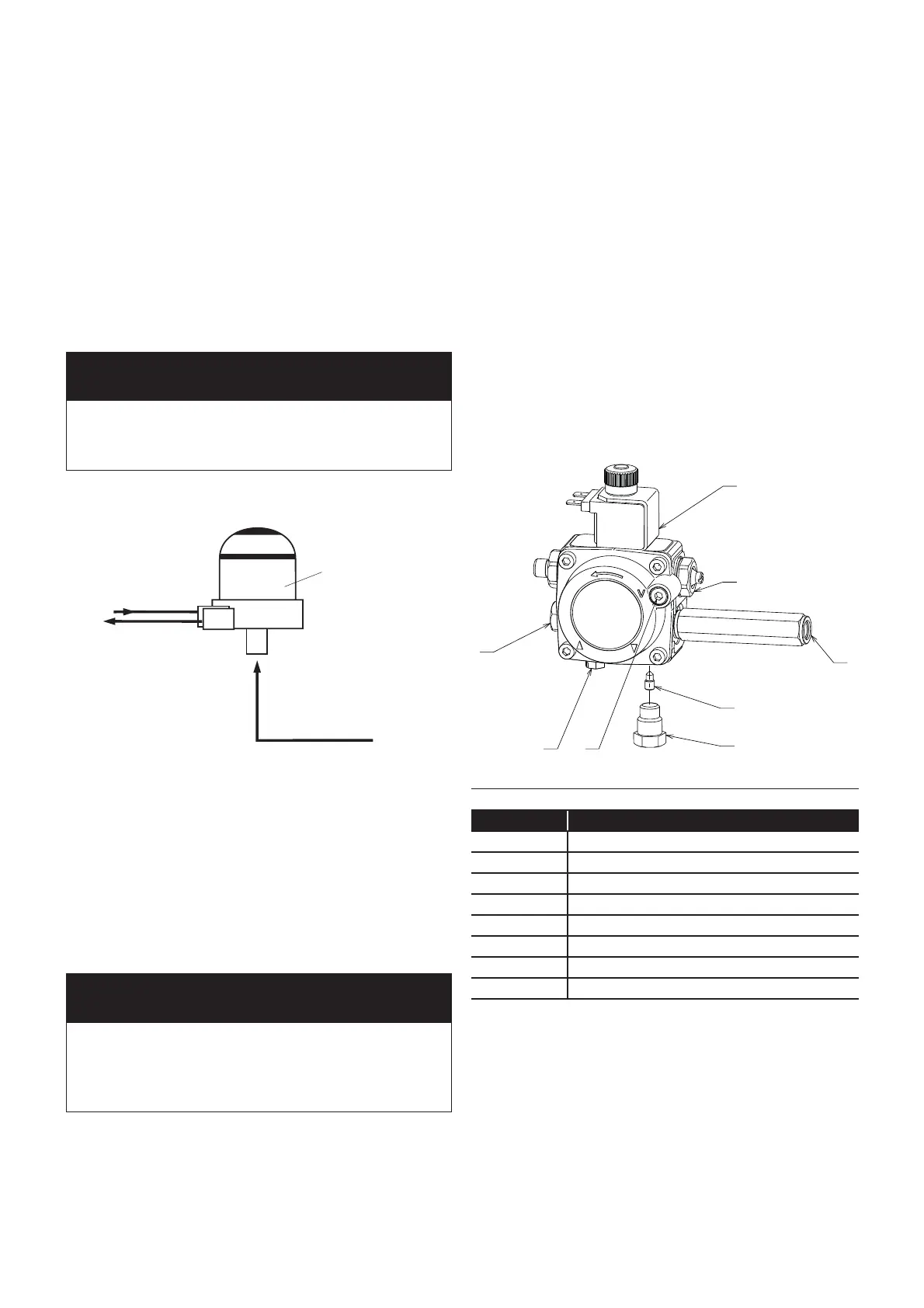

1/4" BSP female

connections

Tiger Loop

SUPPLY

TO PUMP

RETURN

FROM PUMP

SUPPLY

FROM TANK

Figure 3-4: Tiger loop de-aeration device

An external deaerator must not be fi tted within 500 mm of a fl ue

terminal.

Always follow the manufacturers installation instructions supplied

with the deaerator.

To use a de-aertor, the following additional items will be required:

• Flexible fuel hose 3/8 male x ¼ female, 630 mm long (product

code: 20022601)

• 3/8x ¼” BSP adaptor (product code: 3005720)

These are available to purchase from Grant Ireland.

3.2 BURNER OIL CONNECTION

! WARNING !

The blanking plug supplied in the inlet (suction) port is

plastic and will not provide an oil tight seal when the pump

is running.

Ensure that the supply from the tank is connected to this

port and that the plastic plug is discarded.

The burner fuel pump is supplied factory set for use with a single

pipe (gravity) oil supply system.

For ease of access to the burner oil pump connections, the burner

should be removed from the boiler as follows:

1. Remove the red plastic burner cover.

• 15/26, 26/36 & 36/46kW models:

Unscrew and remove the TWO fixing screws from the

red burner cover and remove the cover from the burner.

• 46/70 models:

Unscrew and remove the THREE fixing screws from the

red burner cover and remove the cover from the burner.

2. Unscrew and remove the single burner fixing nut from the

stud on the burner flange (at the top of the burner) using a 13

mm spanner. Retain the fixing nut for re-fitting the burner.

3. Carefully withdraw the burner from the boiler.

3.2.1 SINGLE PIPE (GRAVITY) CONNECTION -

REFER TO FIGURE 3-5

Connect the oil supply to the burner oil pump as follows:

1. Unscrew and remove the plastic blanking plug from the

suction port of the burner oil pump and discard it.

2. Fit the nut of the elbow connection on the fl exible fuel hose

(supplied with the boiler) into the suction port and tighten.

3. Fit the ¼ isolating valve (supplied with the boiler) to the end

of the rigid oil supply pipe using a fi tting to suit the pipe size

and type (not supplied).

4. Connect the other end of the fl exible fuel hose to the isolating

valve using the x ¼ BSP adaptor (supplied with the

boiler).

5. Re-fi t the burner to the boiler. Refer to Section 3.3.

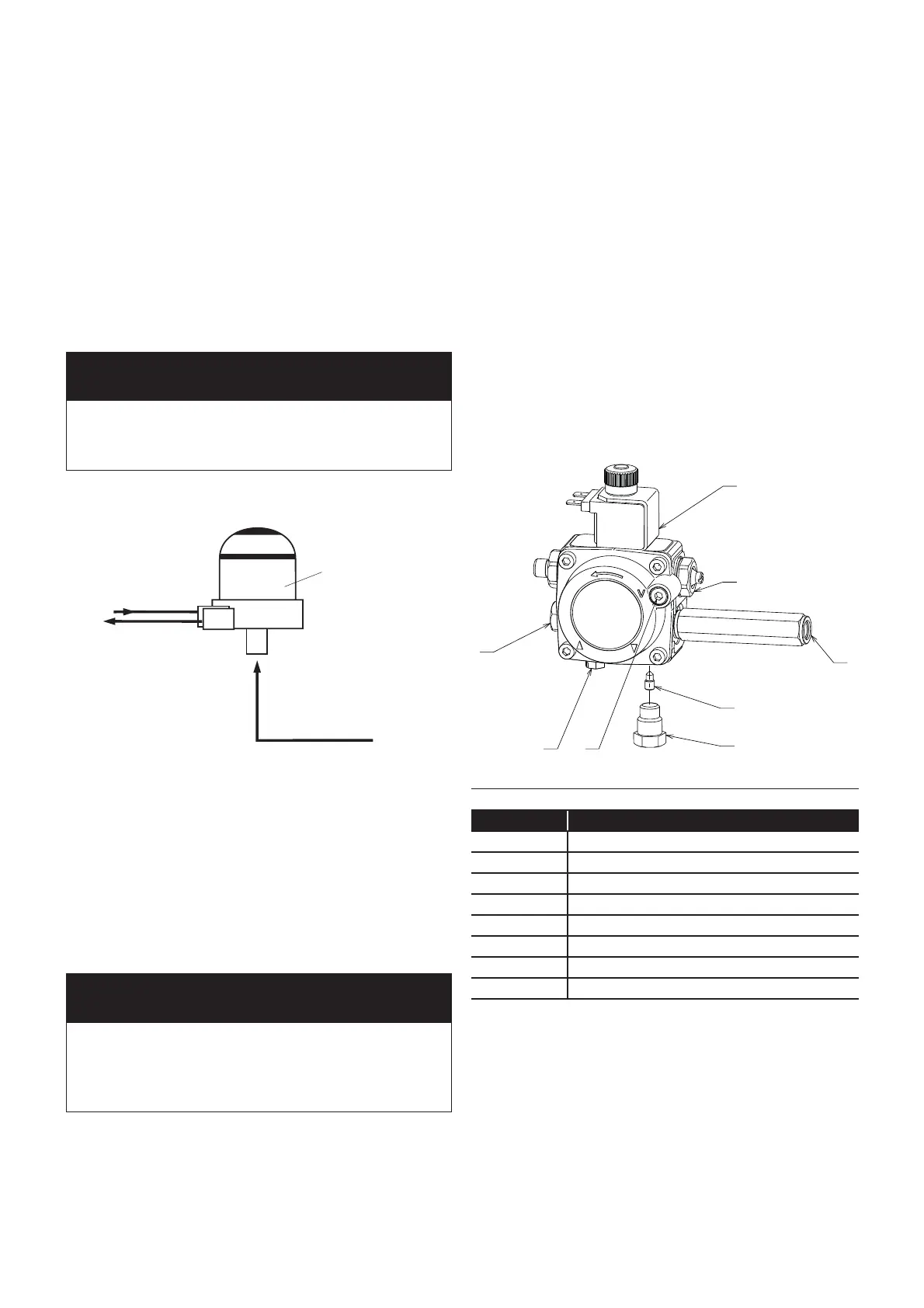

2

3

5

6

7

1

8

4

Figure 3-5: Riello RDB pump

Table 3-1: Key to Riello RDB pump

Item Description

1 Inlet (suction) port

2 Return port

3 By-pass screw

4 Pressure gauge port

5 Pressure adjustment

6 Vacuum gauge port

7 Solenoid

8 Auxiliary pressure test point

Loading...

Loading...