24

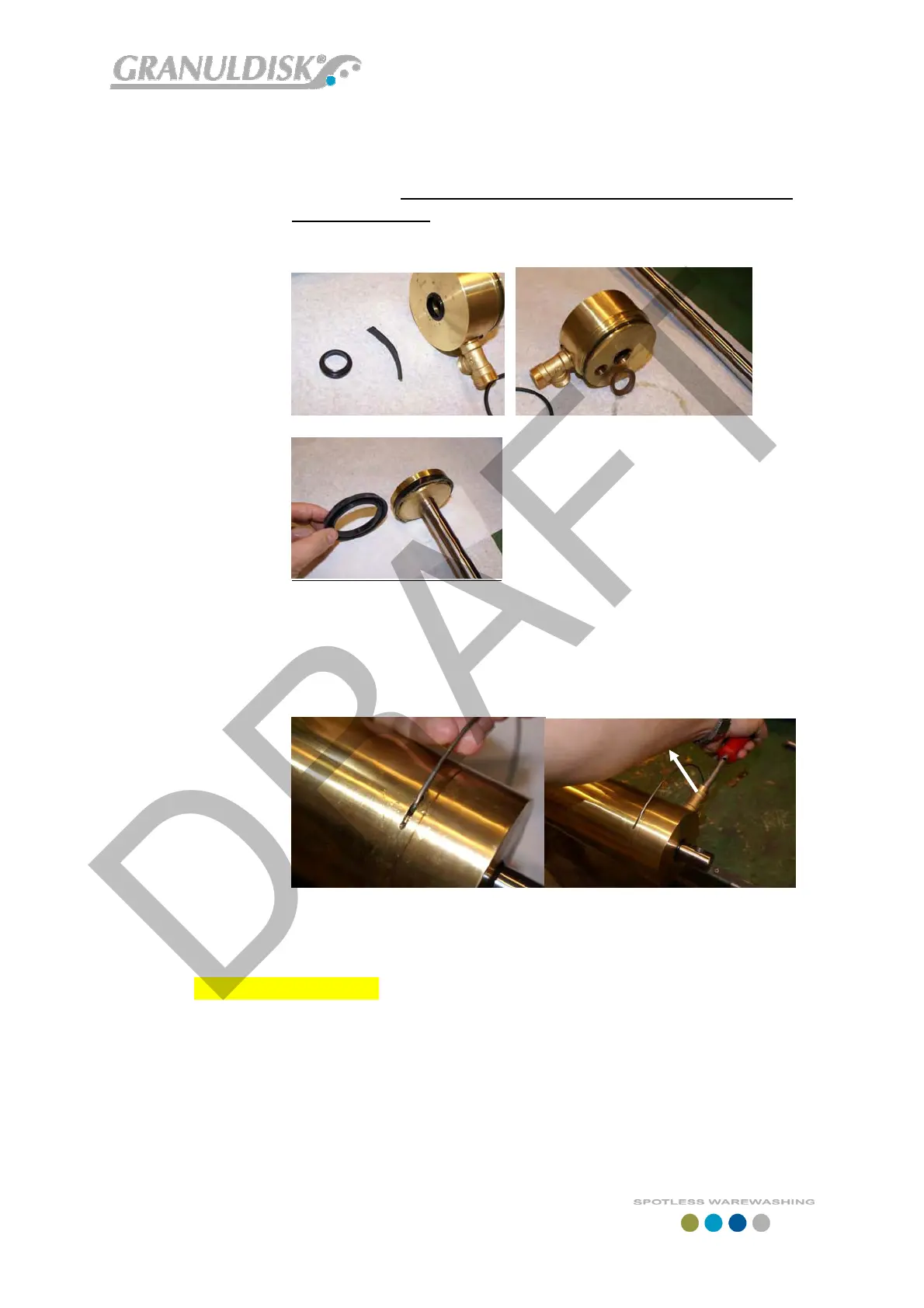

6. Clean all grooves for new parts and apply a little lubrication

grease.

7. Assembly new parts on the piston and on the gable.

Important: Note a correct position of the piston gasket and

the shaft gasket! (The second O-ring belongs to the upper

gable; replace this only in a case of leakage between upper

gable and the cylinder body.)

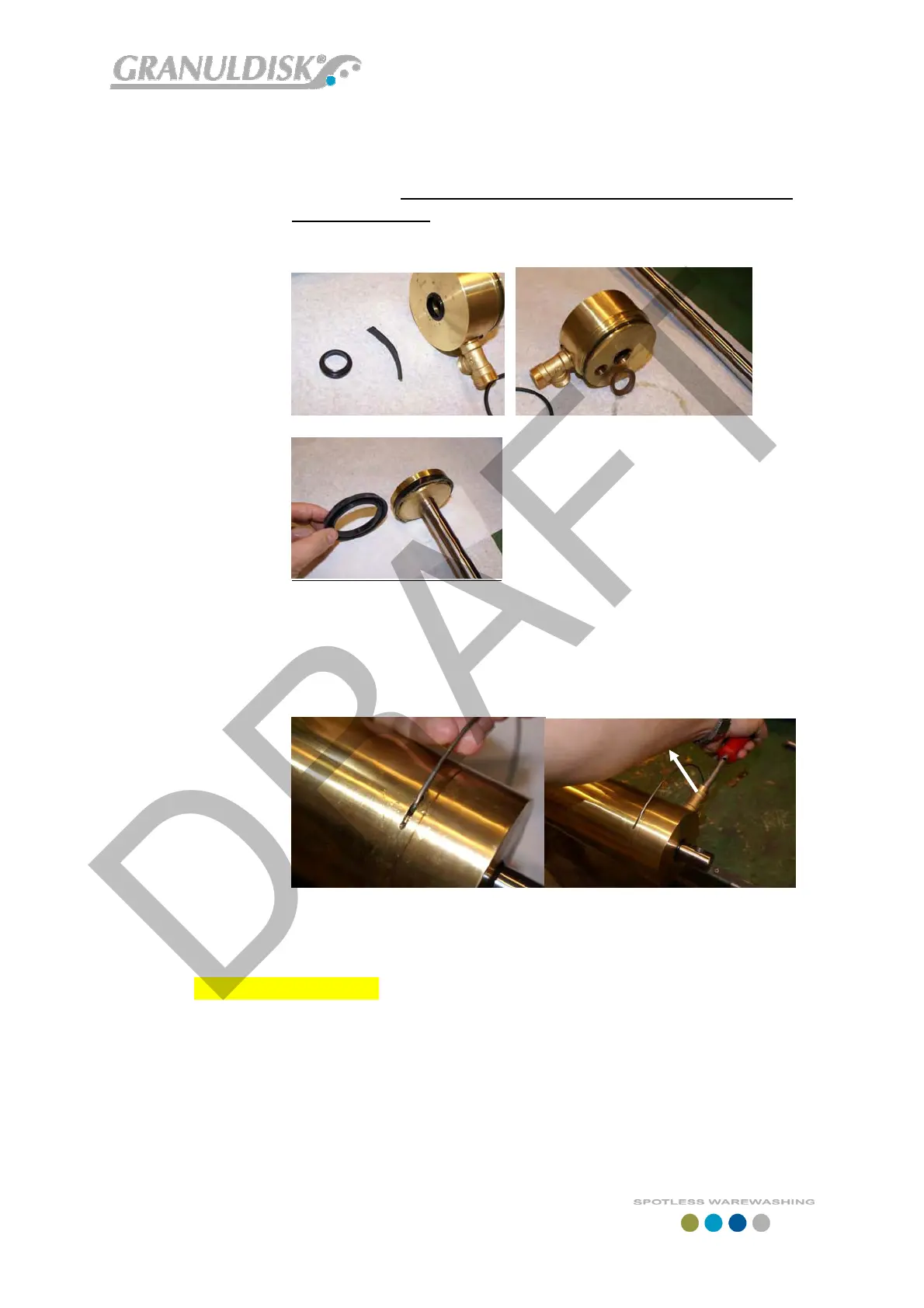

8. Apply the lubrication grease on new parts (richly on the piston

gasket) and finish assembly of the cylinder. The holes for the

locking spring in the gable and the cylinder body have to be

positioned the same point, to pull this spring in easily. The

gable has to be turned anti-clockwise until a sound of click

hears.

9. Connect both hoses to the T-coupling and attach the piston

shaft to the yoke.

10. Start the machine and check the hood motion, function of the

security switch and crush protection. (Section 2/b)

g. Exchange of panel.

3. Rinse system

a. Cleaning of rinse system.

1. Make sure the machine is turned off.

2. Run the rinse pump using Flashloader software to empty the

rinse tank

3. Empty the last water through the rinse plug. Deflect the water

out of the machine. ( Caution content may be hot. )

Loading...

Loading...