Start-Up Components

Fans

All ERV models except ERV-

10 contain two forward curved

(supply and exhaust) fans.

These forward curved fans

should be checked for free

rotation. If any binding occurs,

check for concealed damage

and foreign objects in the fan

housing. Be sure to check

the belt drives per the start-

up recommendations in the

following section.

CAUTION

When operating conditions of the fan are to be

changed (speed, pressure, temperature, etc.), consult

Greenheck to determine if the unit can operate safely

at the new conditions.

4. Align fan and motor sheaves with a straight-edge or

string and tighten.

5. Place belts over sheaves. Do not pry or force belts,

as this could result in damage to the cords in

thebelts.

6. With the fan off, adjust the belt tension by

moving the motor base. (See Fan Belts for more

information). When in operation, the tight side of

the belts should be in a straight line from sheave to

sheave with a slight bow on the slack side.

Fan Performance Modifications

Due to job specification revisions, it may be necessary

to adjust or change the sheave or pulley to obtain

the desired airflow at the time of installation. Start-up

technician must check blower amperage to ensure that

the amperage listed on the motor nameplate is not

exceeded. Amperage to be tested with access doors

closed and ductwork installed.

Fan Belt Drives

The fan belt drive components, when supplied by

Greenheck, have been carefully selected for the

unit’s specific operating condition. Utilizing different

components than those supplied could result in unsafe

operating conditions which may cause personal injury

or failure of the following components:

• Fan Shaft • Bearings • Motor

• Fan Wheel • Belt

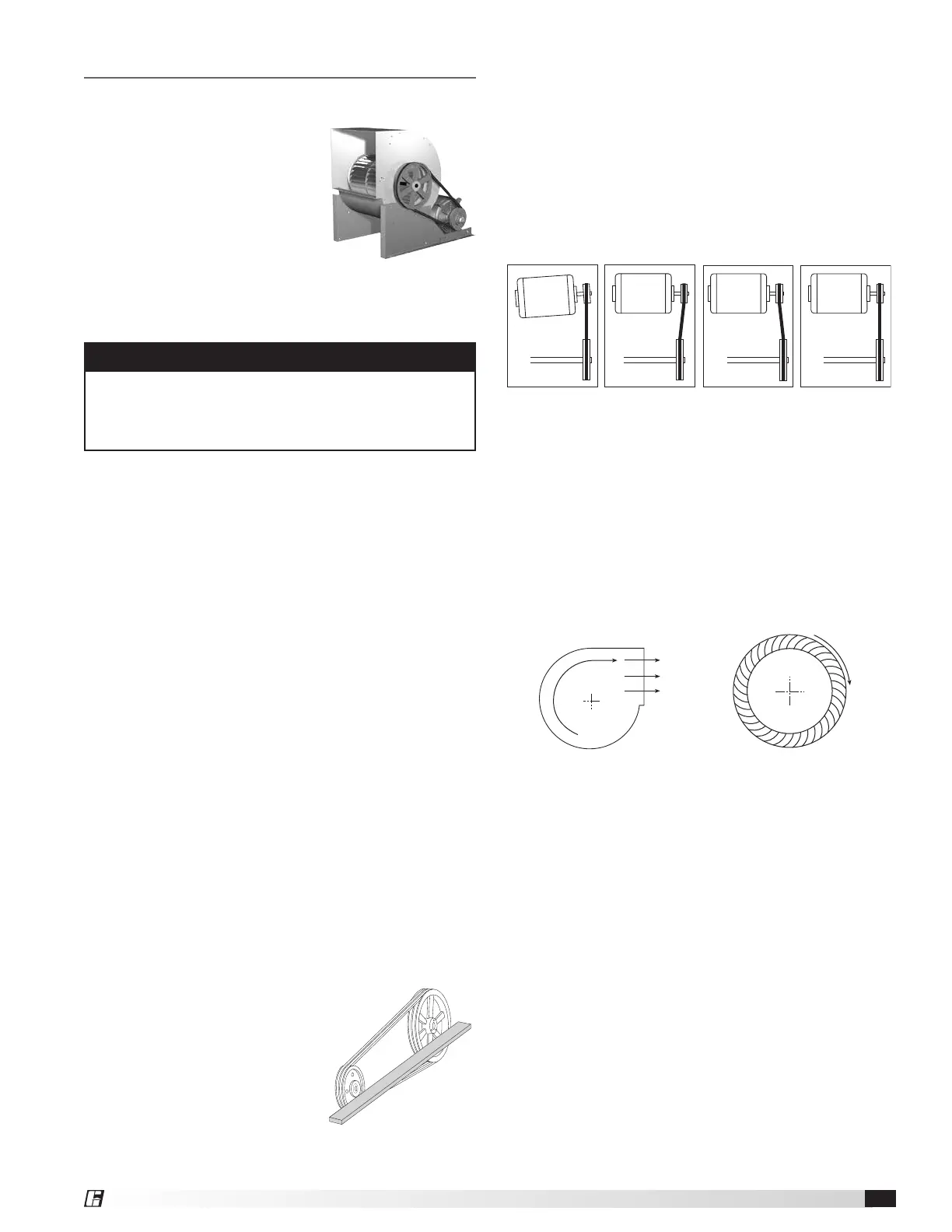

Tighten all fasteners, set screws securely, and realign

drive pulleys after adjustment. Check pulleys and belts

for proper alignment to avoid unnecessary belt wear,

noise, vibration, and power loss. Motor and drive shafts

must be parallel and pulleys in line (see diagrams in this

section).

Fan Belt Installation

1. Remove the protective coating from the end of the

fan shaft and assure that it is free of

nicks andburrs.

2. Check fan and motor shafts

for parallel and angular

alignment.

3. Slide sheaves on shafts.

Do not drive sheaves

on as this may result in

bearingdamage.

Belt Span

Deflection =

Belt Span

64

WRONGWRONG

WRONG CORRECT

WRONGWRONG

WRONG CORRECT

Forward Curved

Exhaust Fan

Direction of Fan Wheel Rotation

Blower access is labeled on unit. Check for proper

wheel rotation by momentarily energizing the fan.

Rotation is determined by viewing the wheel from the

drive side and should match the rotation decal affixed

to the fan housing (see Rotation Direction figures

below). If the wheel is rotating the wrong way, direction

can be reversed by interchanging any two of the three

electrical leads. Check for unusual noise, vibration, or

overheating of bearings. Refer to the Troubleshooting

section of this manual if a problem develops.

Fan RPM

Supply fan and exhaust fan will have an adjustable

motor pulley (on 15 HP and below) preset at the factory

to the customer specified RPM. Fan speed can be

increased or decreased by adjusting the pitch diameter

of the motor pulley. Multi-groove variable pitch pulleys

must be adjusted an equal number of turns open

or closed. Any increase in fan speed represents a

substantial increase in load on the motor. Always check

the motor amperage reading and compare it to the

amperage rating shown on the motor nameplate when

changing fan RPM. All access doors must be installed

except the control center door. Do not operate units

with access doors open or without proper ductwork

in place as the fan motors will overload.

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

Backward Inclined

Forward Curved

Airflow

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

Backward Inclined

Forward Curved

Energy Recovery Ventilator 19

Loading...

Loading...