Cleaning the Energy Recovery Wheel

If the wheel appears excessively dirty, it should be

cleaned to ensure maximum operating efficiency. Only

excessive buildup of foreign material needs to be

removed. Discoloration and staining of energy recovery

wheel does not affect its performance.

Thoroughly spray wheel matrix with household cleaner

such as Fantastik

®

or equivalent. Gently rinse with

warm water and using a soft brush remove any heavier

accumulation. A detergent/water solution can also

be used. Avoid aggressive organic solvents, such as

acetone. The energy recovery wheel segments can be

soaked in the above solution overnight for stubborn dirt

or accumulation.

After cleaning is complete, shake the excess water

from the wheel or segments. Dry wheel or segments

before placing them back into the cassette. Place wheel

or segments back into cassette by reversing removal

procedures.

CAUTION

Do not clean energy recovery wheel segments with

water in excess of 140ºF (60ºC).

Do not dry energy recovery wheel segments in air in

excess of 140ºF (60ºC).

The use of a pressure washer to clean segments is

not recommended. Damage could result.

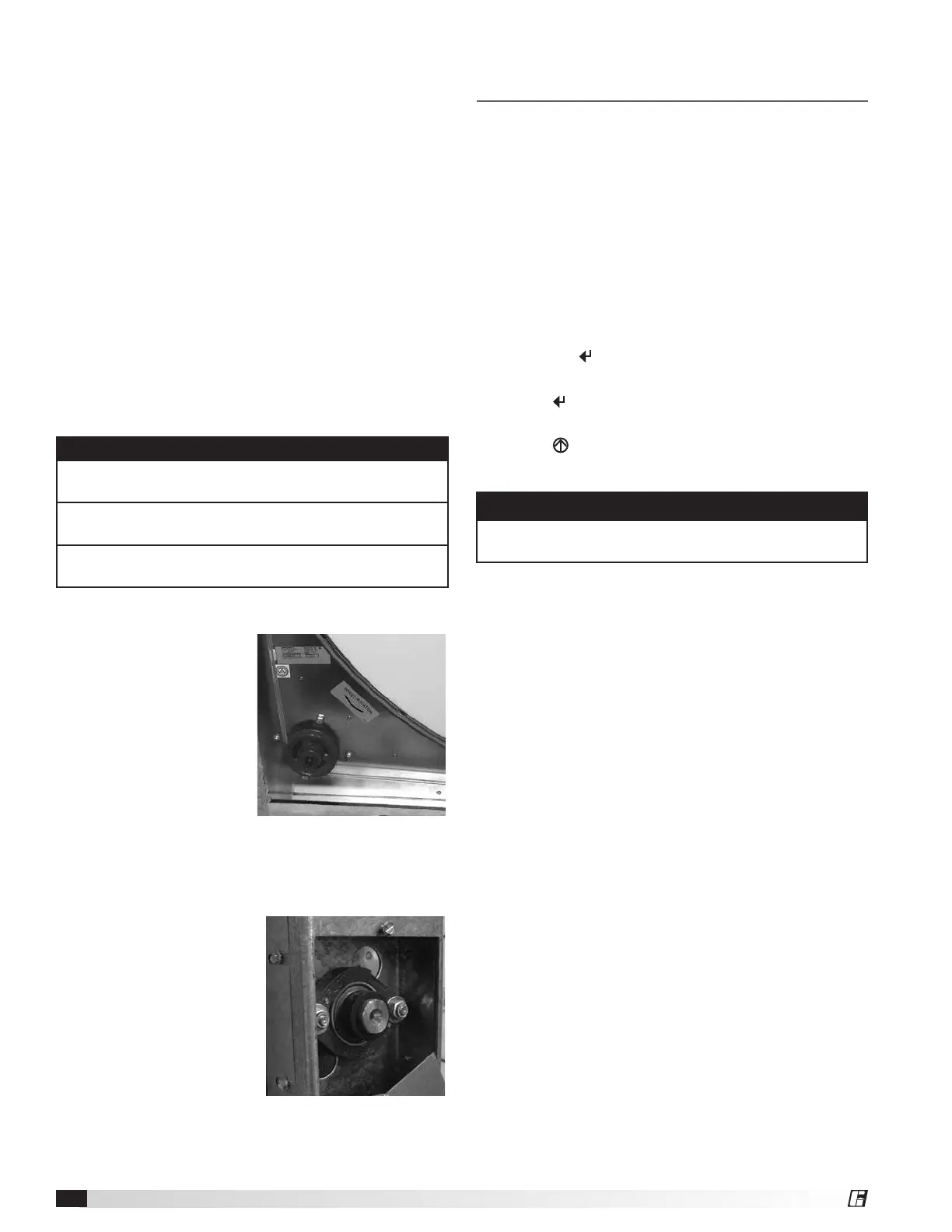

Energy Recovery Wheel Belt

Inspect belts each time

filters are replaced. Belts

that look chewed up

or are leaving belt dust

near the motor pulley

may indicate a problem

with the wheel. Be sure

to inspect wheel for

smooth and unrestricted

rotation. If a belt requires

replacement, contact

the local Greenheck

representative. Instructions

for replacement will ship with the new belt.

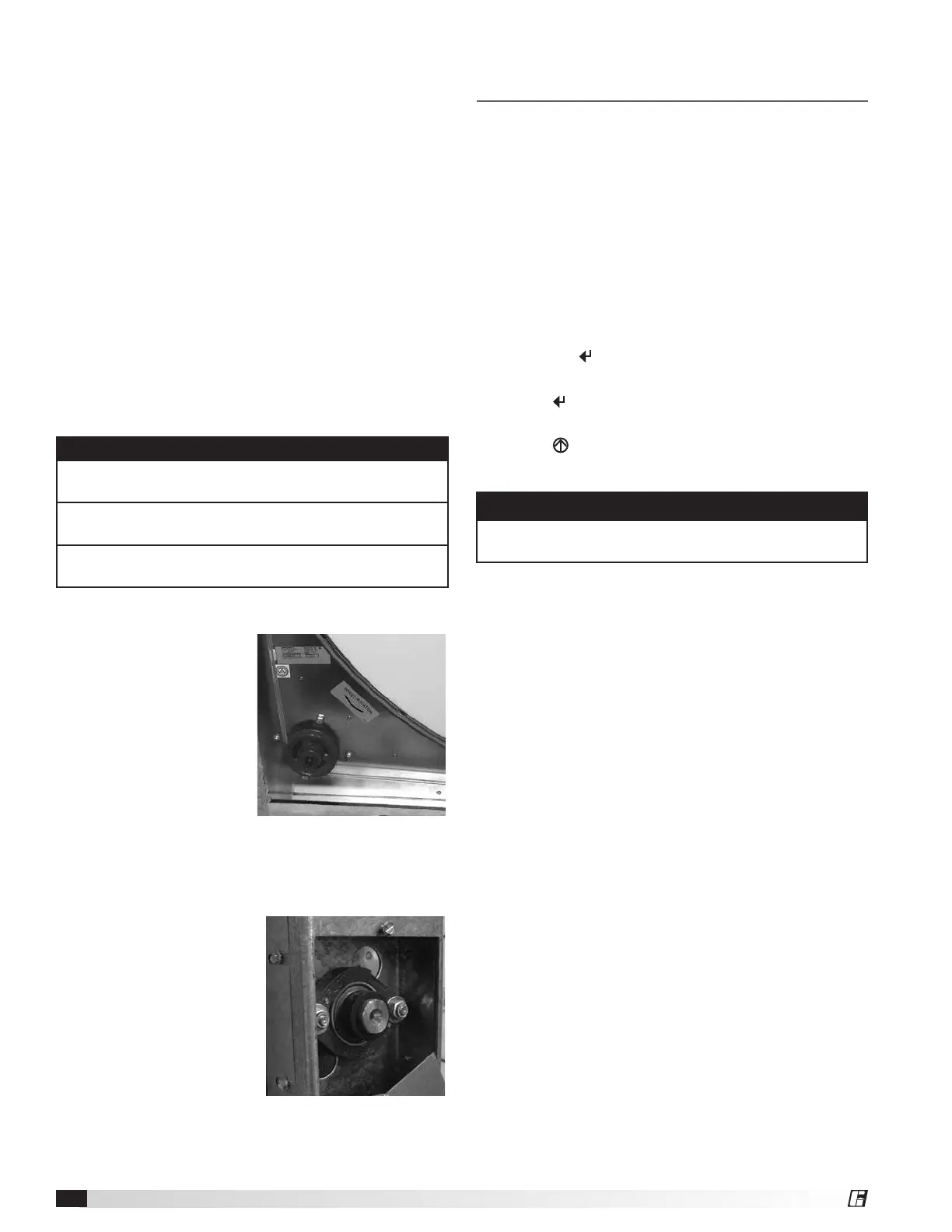

Energy Recovery Wheel Bearing

In the unlikely event that

a wheel bearing fails,

the bearing is behind a

removable plate on the

wheel support beam which

is accessible through the

outdoor air filter door (and

exhaust filter door on the

ERV-90 and 120). Contact

the local Greenheck

representative for detailed

instructions on how to

replace the bearing.

Wheel Bearing

Wheel Belt & Pulley

Troubleshooting - Economizer

Alarms

Addressing Alarms

Alarms will signify a faulty sensor. When this occurs,

verify all connections to the sensor and controller are

secure. Press enter twice to clear the alarm. If the issue

persists, consult the factory.

Clearing Alarms

Once the alarm has been identified and the cause has

been removed (e.g. replaced faulty sensor), the alarm

can be cleared from the display.

To clear an alarm, perform the following:

1. Navigate to the desired alarm.

2. Press the

(enter).

3. ERASE? displays.

4. Press

(enter).

5. ALARM ERASED displays.

6. Press

(escape) to complete the action and return

to the previous menu.

NOTE

After clearing the alarm, it will redisplay after five

seconds.

Energy Recovery Ventilator28

Loading...

Loading...