CO

2

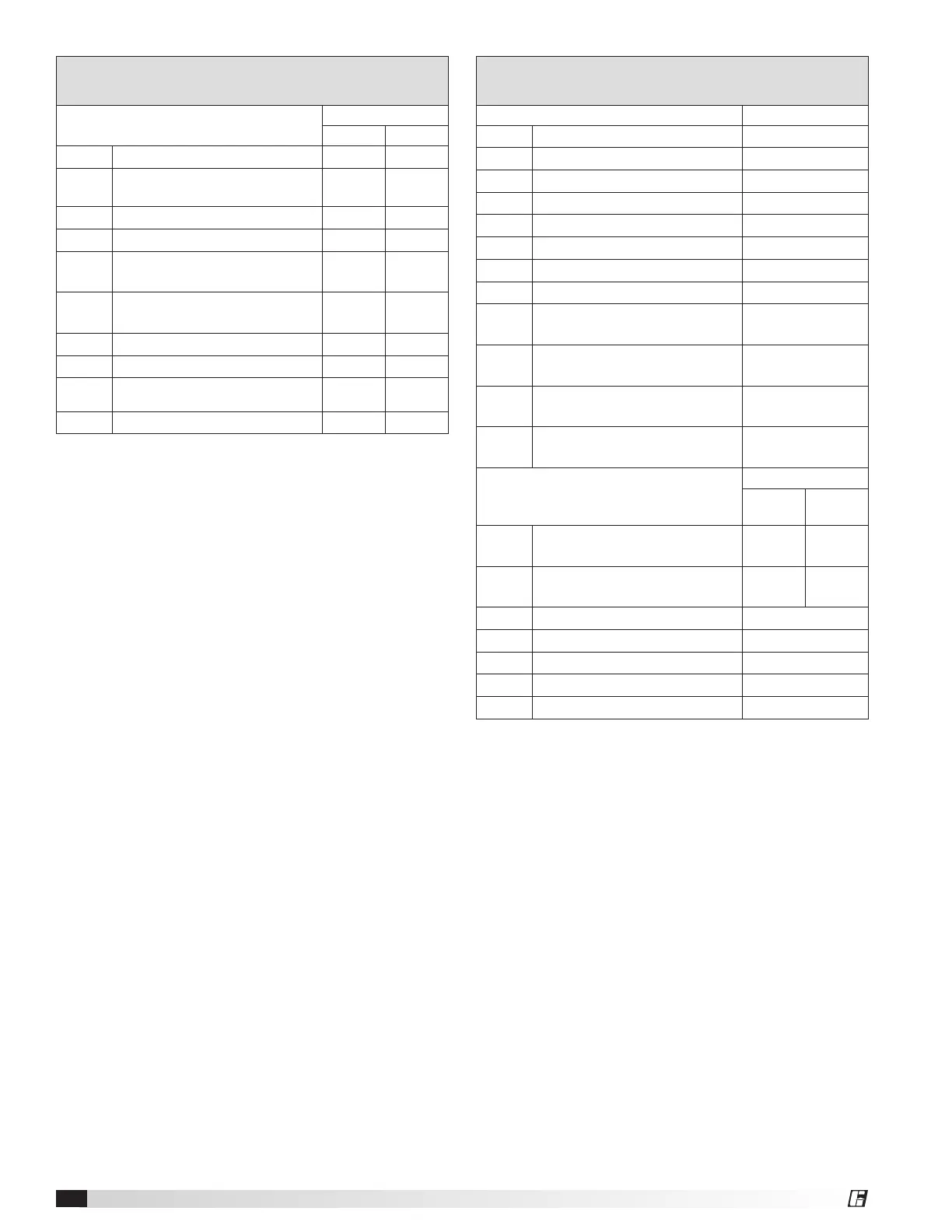

PROPORTIONAL CONTROL

Parameter

Setting

V1000 J1000

B1-17 VFD Start-Up Setting 1 1

C6-02 Carrier Frequency 1 1

D2-02 Ref Lower Limit 50% 50%

E2-01 Motor Rated FLA FLA FLA

H3-03

Analog Frequency

Reference (Gain)

150% 150%

H3-04

Analog Frequency

Reference (Bias)

25% 25%

L2-01 Ride Thru Power Loss 2 2

L4-05 Frequency Ref Loss 0 NA

L5-01 Auto Restart Attempt 5 5

A1-01 Access Level 0 0

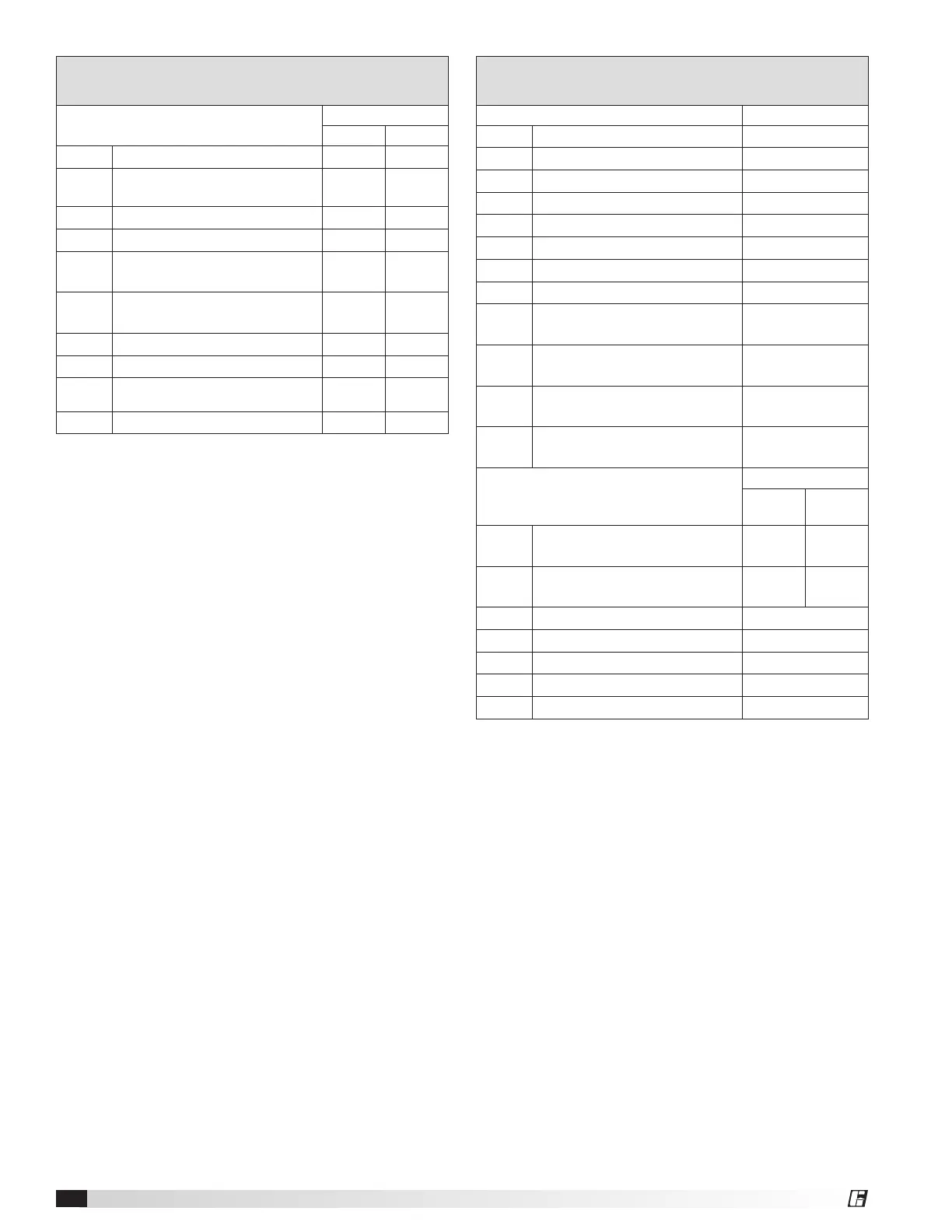

VARIABLE FREQUENCY DRIVES

FOR ENERGY RECOVERY WHEEL

Parameter Setting – J1000

A1-01 Access Level 2

B1-17 VFD Auto Start 1

C1-04 Decel Time 600

*C4-01 Torque Gain 0.6

C6-02 Carrier Frequency 2

D2-01 Ref Upper Limit 40 or 50*

D2-02 Ref Lower Limit 5%

E2-01 Motor Rated FLA Motor FLA

E2-03 Motor No-Load Current

Must be less

than FLA

H1-02

Multi-Function Input

(Terminal S2)

6

H2-01

Multi-Function Output

(MA, MB, MC)

4

H1-04

Multi-Function Input Sel 4

(Terminal S4)

7

Economizer Signal Source

(0-10 VDC)

Setting

Honeywell

Module

Carel

Controller

H3-03

Analog Frequency

Reference (Gain)

0

40 or

50*

H3-04

Analog Frequency

Reference (Bias)

40 or

50**

0

L1-01 Elect Thermal Overload 2

L2-01 Ride Thru Power Loss 2

L4-01 Frequency Detection Level 15

L5-01 Auto Restart Attempt 5

A1-01 Access Level 0

* 208/230 volt only

**36 through 52 inch wheels are 40 (24 Hz)

58 or 74 inch wheel is 50 (30 Hz)

Energy Recovery Ventilator24

Loading...

Loading...