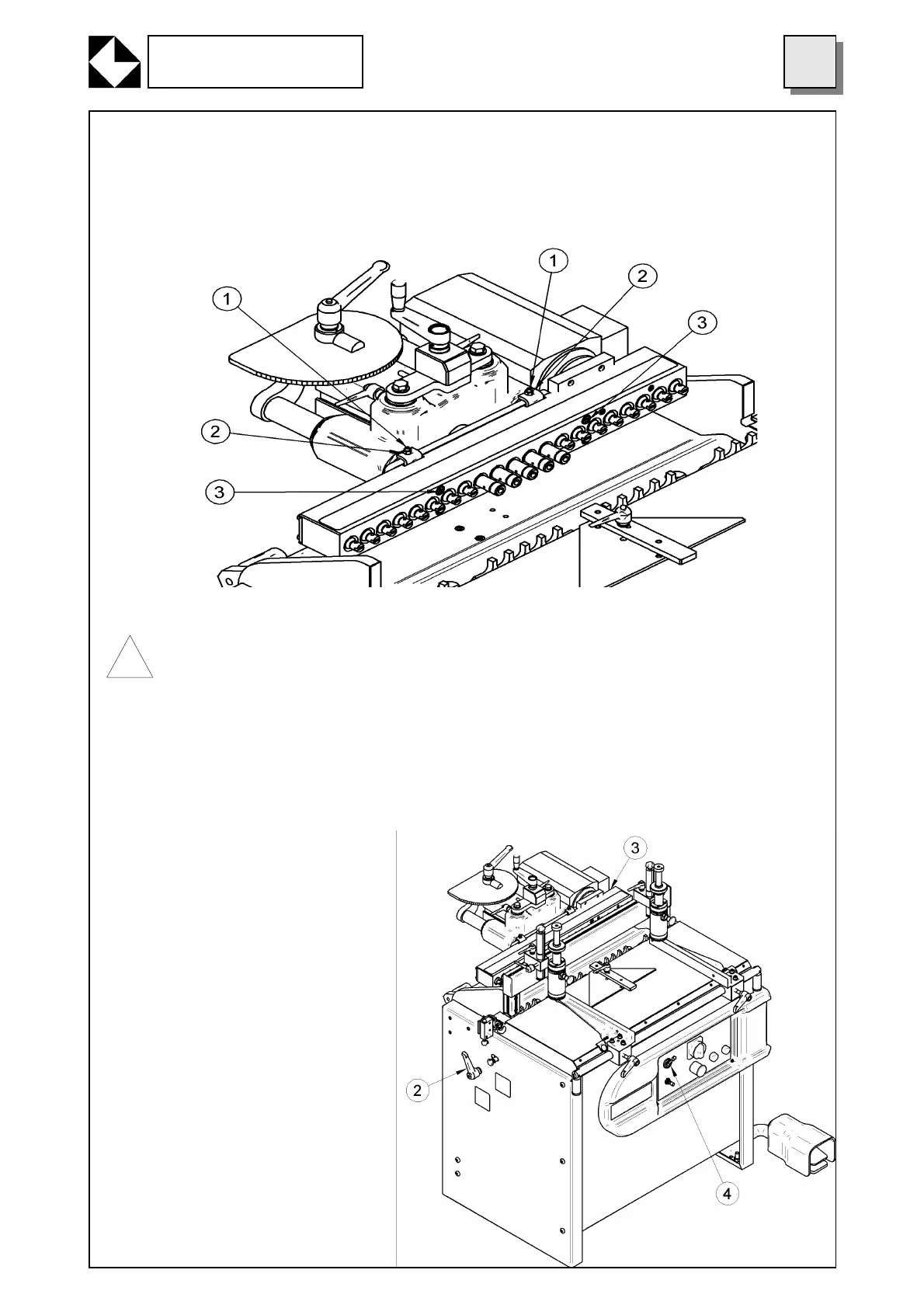

16.4 HOW TO ADJUST HEAD PARALLELISM

To adjust head parallelism according to the working table:

- partially unscrew the screws (3) and operate alternatively on the screws (1) and screw nuts (2)

- position the drills parallel to the table

- tighten the screws very well (3)

WARNING DANGER!

Follow the procedure described below very carefully.

To position the spindlehead at 90°, follow this procedure:

With spindlehead at 0°:

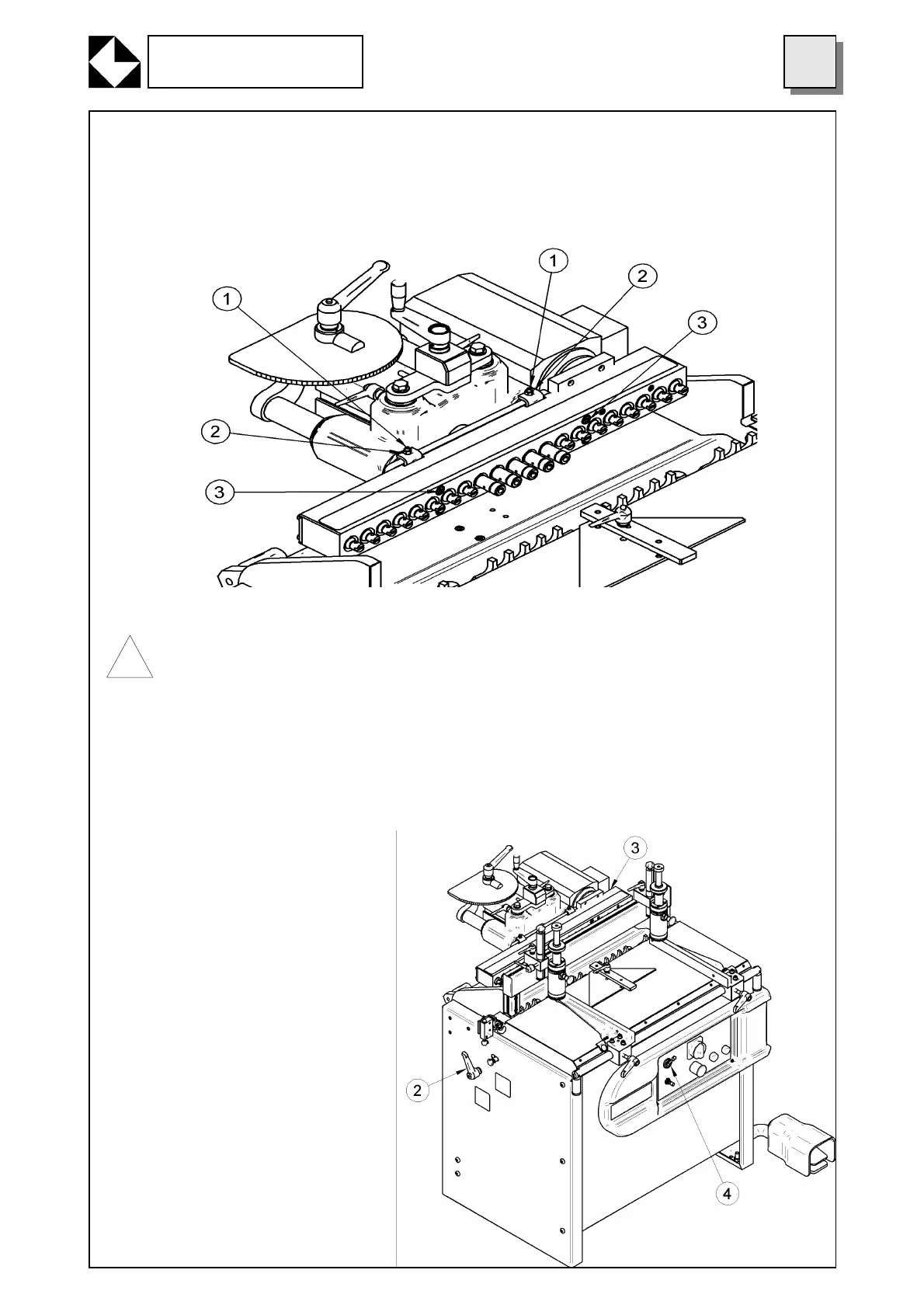

Unfasten the head by turning the handle (2) located on the left-hand side of the machine.

Operate on the boring head (3), by switching the lever (4) located at the front of the machine; lock the

head into position by tightening the handle (2).

To position the spindlehead at 0° do as follows:

With spindlehead at 90°:

Make sure the lever at the front of the

machine is also set at 90° and that the

pneumatic system is on (hence overturn-

ing lever must be active)

Unclamp spindlehead clamping handle

(2) on the left-hand side of the machine.

SELECT 0° POSITION WITH HEAD-

POSITIONING LEVER (4). ONCE THE

HEAD IS IN ITS NEW POSITION

CLAMP IT WITH THE CLAMPING HAN-

DLE (2).

How to set Spindlehead at 45°

If the spindlehead is set at 0°:

- Make sure the head-overturning lever

(4) is also at 0° and that pneumatic pres-

sure in the pneumatic system is correct.

- Insert lock at 45°in locking position;

- Clamp head-clamping handle (2);

- Lower head-rotating lever (4) located

in the front of the machine at 90°;

- Once the machine has been set at

45°, tighten the clamping handle until it is

clamped (2).

16.5 HOW TO POSITION SPINDLEHEAD VERTICALLY AND HORIZONTALLY

15

GRIGGIO S.p.A.

WOODWORKING MACHINERY

!

PICT A

Loading...

Loading...