A

17 HOW TO START THE MACHINE

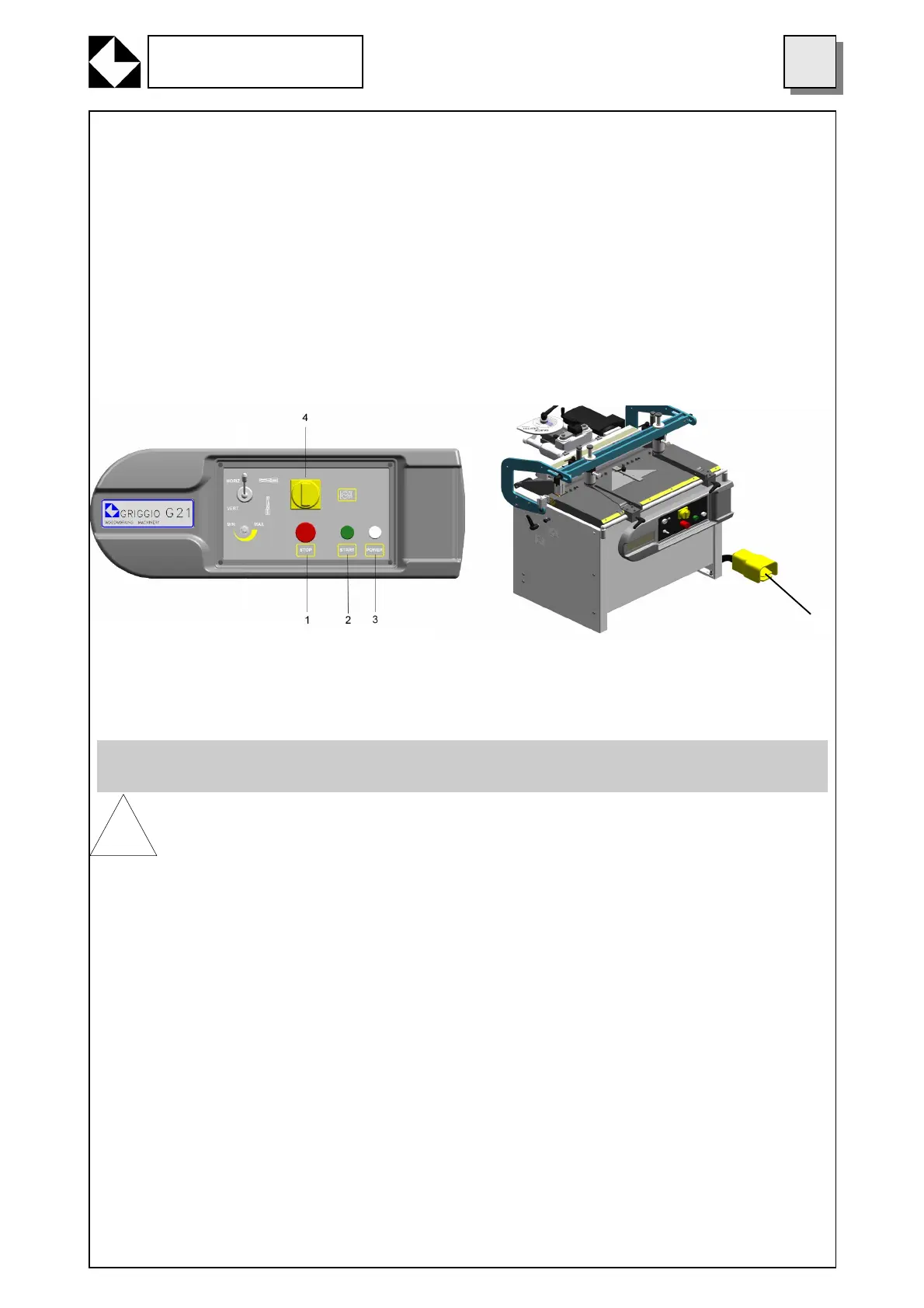

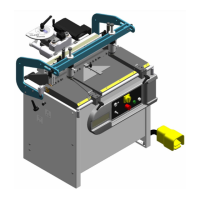

The operator’s site and the control board are located in front of the electrical control panel of the ma-

chine.

17.1 WORKING CYCLE

After having programmed the machine, follow the instructions given in the following paragraph to start

the working cycle:

1) Turn the main switch (4), set it to position 1 and press MOTOR button (2). The corresponding light

will light up and the machine is ready to start the working cycle.

2) Press the pedal (A); the spindles will turn, the head will progress while the hold down clamps will

block the piece.

3) If the pedal is released, the head will return in its initial position and the spindles will stop.

4) Hold down clamps will release the block

Should you need to interrupt the working cycle, press the emergency pushbutton (1)

18. MAINTENANCE

Adequate servicing is a fundamental factor in guaranteeing longer life to the machine and to keep the

machine itself in good working order.

CAUTION – SLIPPING DANGER!

While cleaning the working area, mind working scraps and liquids on the floor around the ma-

chine, since they might cause the operator to slip.

!

18.1 MACHINE CLEANING (DAILY)

The machine and the working area must be kept clean from wood scraps or any other object that might

hamper the working cycle or might prevent the operator from easily reaching the machine itself. The ma-

chine must be cleaned daily. Make sure that material that is not needed to operate the machine does not

accumulate on the machine itself, thus preventing the machine from functioning safely and jeopardising

the operator during the every day working cycle.

18.2 RAILS CLEANING (WEEKLY)

Rails and slide shafts must be kept clean from working scraps since they might hamper movements of

the machine and damage its performance. Do not use detergents or lubricants.

ELECTRICAL CABLES CHECK:

Check electrical cables condition. Make sure they are not worn out or abraded.

18.3 KINEMATICS CLEANING AND CHECKS (MONTHLY)

Regularly check bearings and gears acoustically and visually inspect the spindlehead and all moving

parts

of the machine (sliding shafts, overturning piston shaft etc.)

21

GRIGGIO S.p.A.

WOODWORKING MACHINERY

All maintenance operations must be carried out while the machine is switched off.

Always wear protective gloves and goggles.

Loading...

Loading...