The extension fence is used to make a set of larger holes than the ones the machine can make or to

bore large pieces. To use the extension fence you usually have to exclude side limiters completely or

partially. To position the extension fence you usually have to exclude side limiters completely or partially

and to set the spindlehead at 90°. If you use the extension fence longitudinally, we advise you to ex-

clude side limiters completely, since it is possible to use mobile reference stops on the extension fence

itself to position the piece to be worked. (The extension fence is provided with 4 mobile stops with posi-

tioning screws, stop screw and extension fence clamping device).

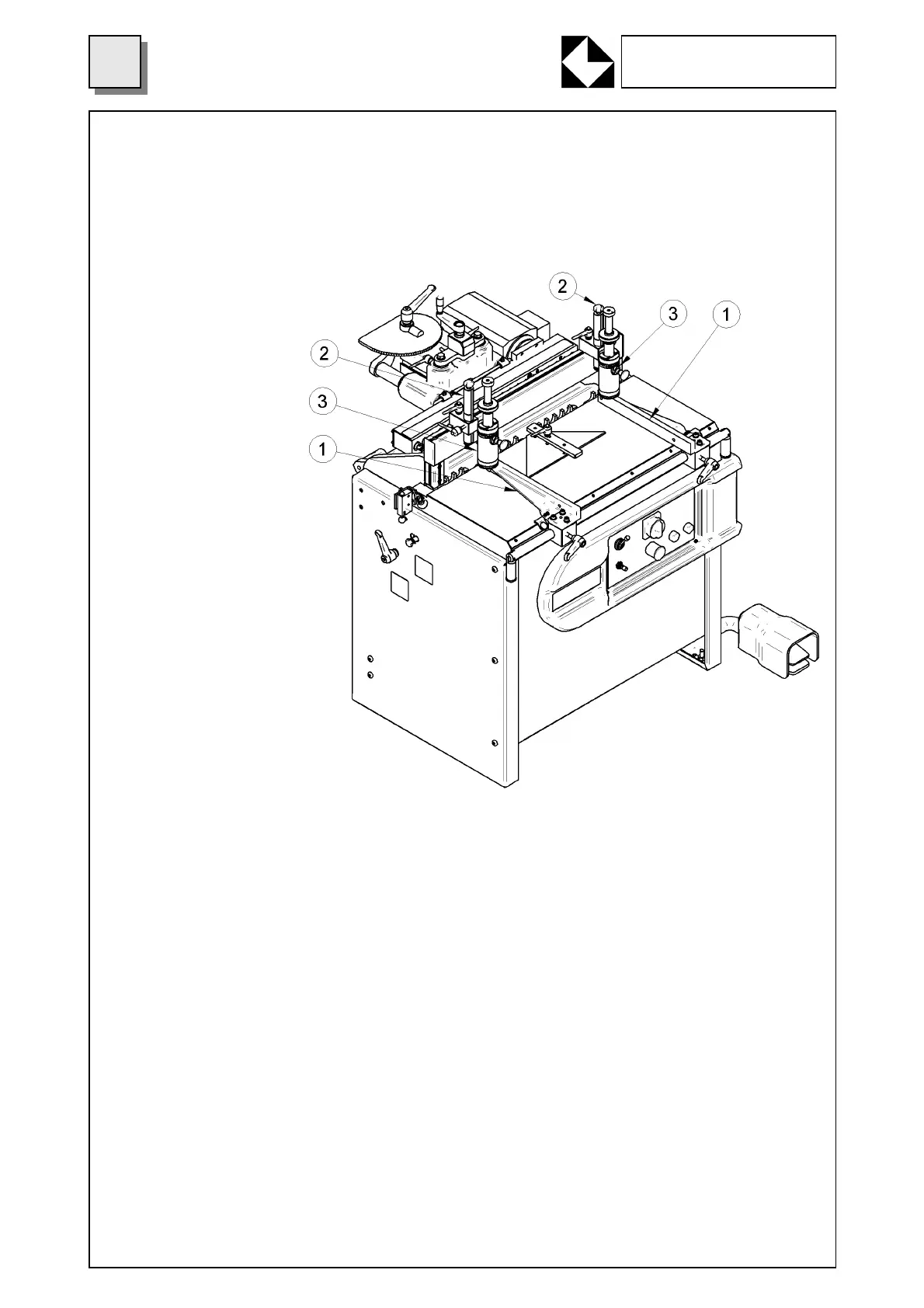

16.6 HOW TO USE REFERENCE STOPS FOR STANDARD 0°-90°WOODWORKING

Side rails and back stops are used to position the piece to be worked in a standard working cycle.

With spindlehead at 90° and spindle unit locked into position:

- Set side rails at the right distance from drills that will be used and fasten them.

- Position the hold-down cylinder (or hold-down cylinders) (3) on the table where the piece to be

worked will be located.

- Position the piece to

be bored against side limit-

ers and use them as rails

to position the piece under

the hold down clamps and

right against the rack.

- Now position the stops

(2) over the piece to be

bored, lower stop refer-

ence block itself on the

piece, and clamp the stop

itself with the handle.

- The piece is in the right

position and it is now pos-

sible to start the working

cycle by pressing the pedal

that starts drills feed with

engine switched on (make

sure engine switch is on).

At the same time hold

down clamps will lock the

piece into position.

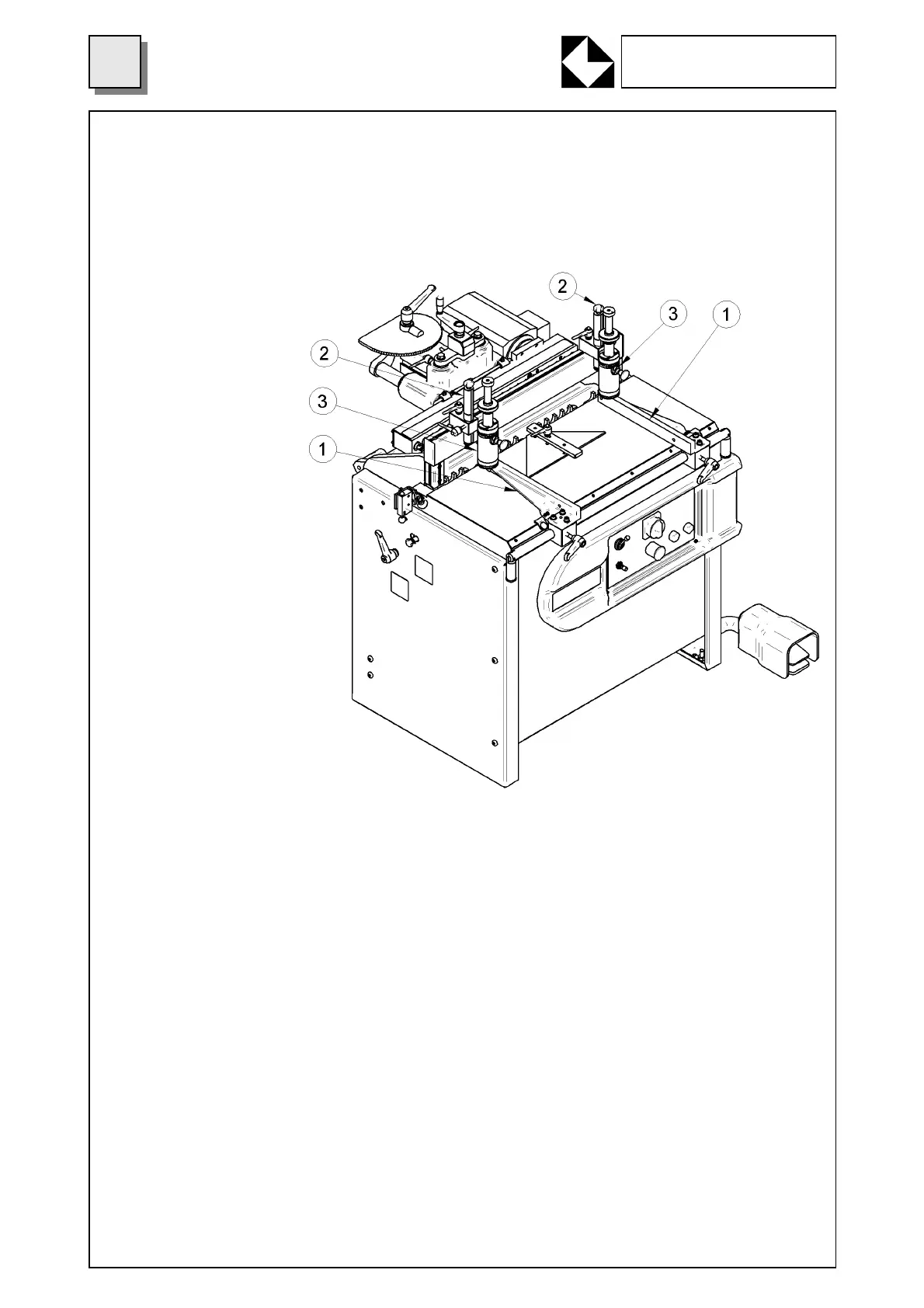

16.7 HOW TO USE EXTENSION FENCE (3000 MM STANDARD)

When the first phase is over, release the pedal to release the piece and take the bored piece out of the

machine.

Unfasten the spindlehead unit and switch the overturning lever to reposition the spindlehead at 90°.

Once the head has been repositioned and locked into position, the second phase can begin:

- Position the piece that has to be joined to one that has just been worked against the side limiter un-

der the hold down clamp (or hold down clamps) (3) and against the back stop block.

- Once you are sure the piece has been positioned correctly, press the pedal to activate hold down

clamp lock, drills rotation and drills feed.

- Once the pedal is released, the piece will be released and the working cycle will be over.

THE TWO PIECES THAT HAVE BEEN OBTAINED (0° -90°) ARE NOW READY TO BE JOINED

GRIGGIO S.p.A.

WOODWORKING MACHINERY

16

Loading...

Loading...