Model G0885 (Mfd. Since 04/19)

-29-

Operation

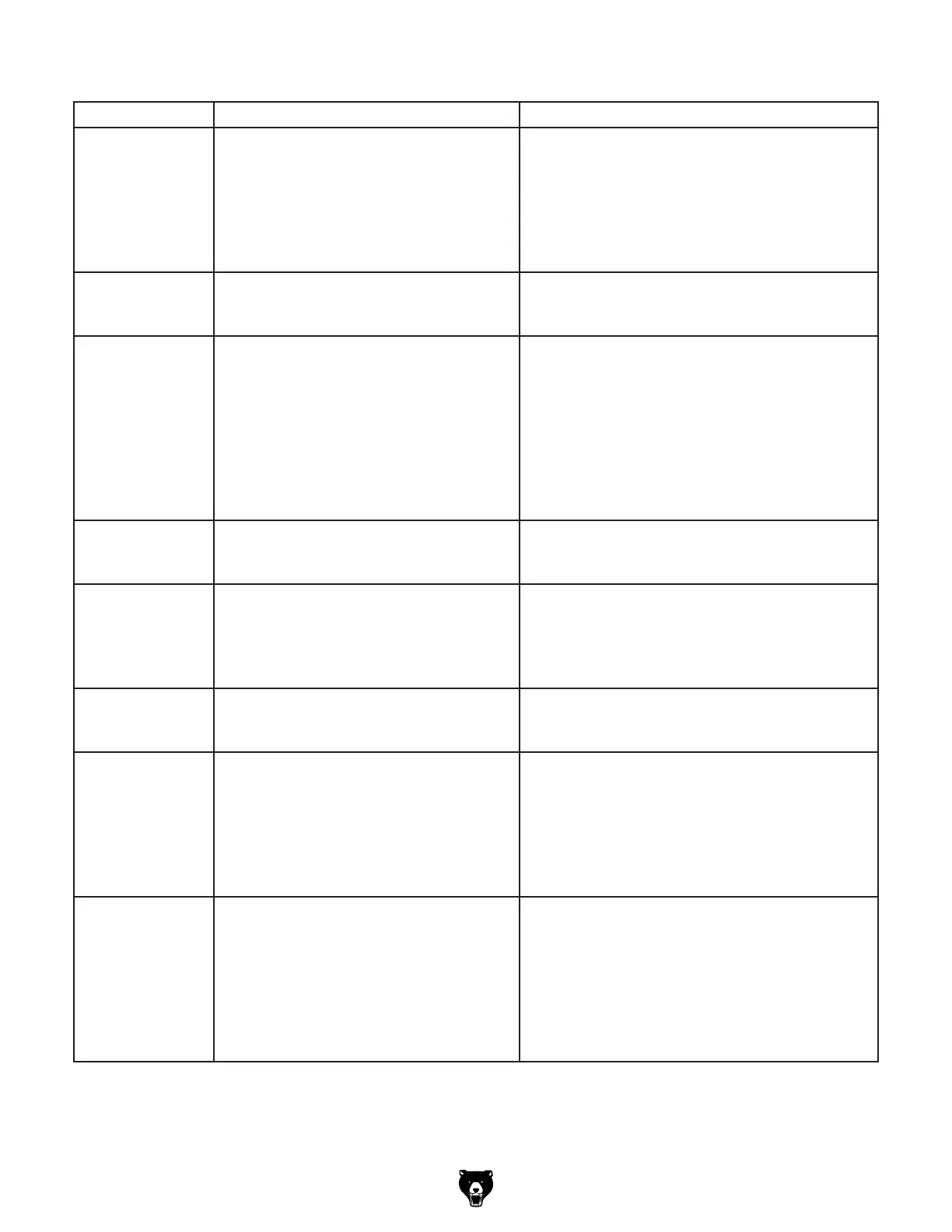

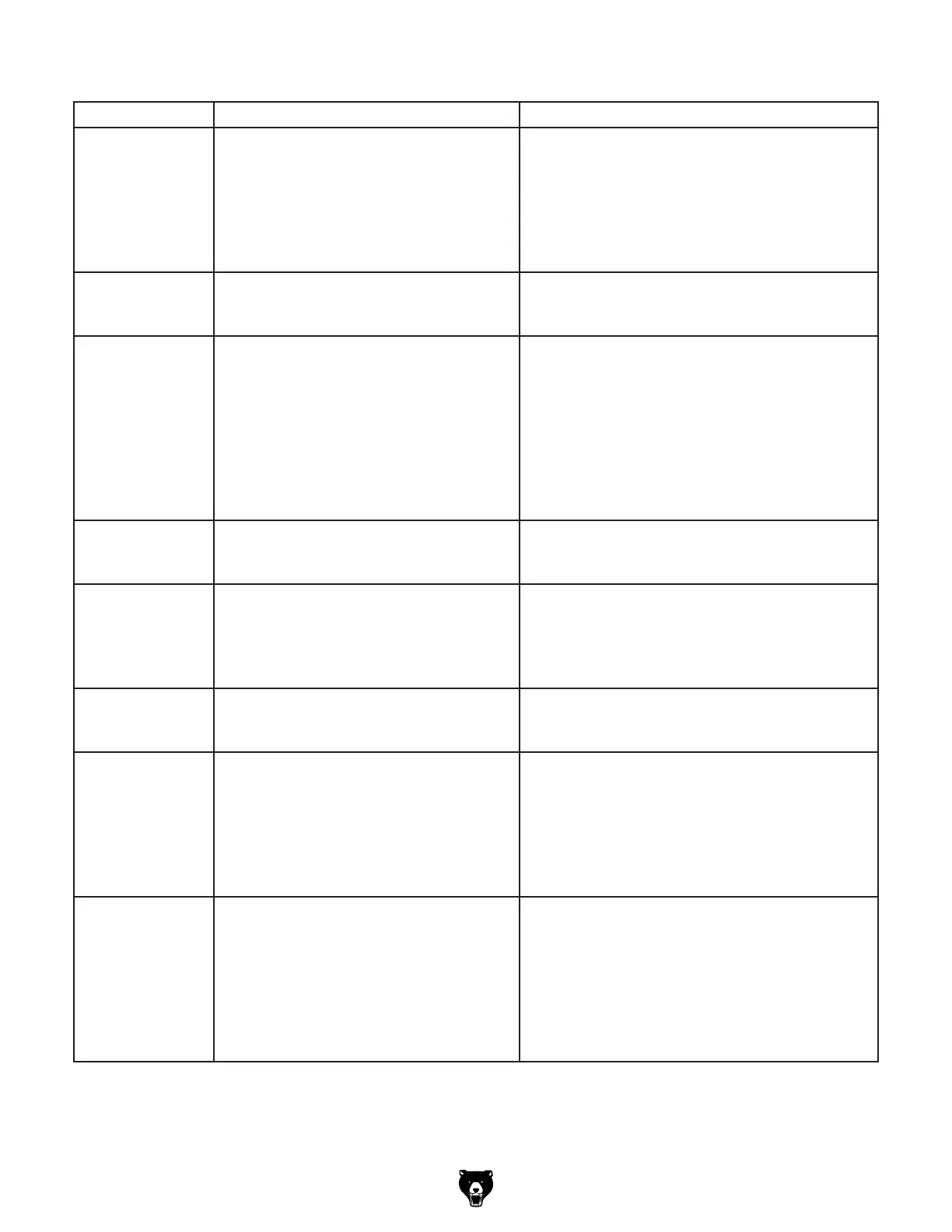

Symptom Possible Cause Possible Solution

Vibration when

operating or cutting.

1. Loose or damaged blade.

2. Bandsaw wheels have contaminants

loaded up on wheel surface.

3. Bent, damaged or dull blade.

4. Machine component loose.

5. Worn wheel bearing.

6. Wheel bent/worn.

1. Tighten or replace blade (Pages 18-19).

2. Remove blade; clean bandsaw wheels.

3. Replace blade (Page 18).

4. Fix/replace fan cover; replace loose/damaged fan.

5. Check/replace wheel bearing.

6. Check/replace wheel and wheel bearing.

Ticking sound when

saw is running.

1. Blade missing teeth.

2. Blade weld contacting blade guides.

3. Blade weld may be failing.

1. Replace blade (Page 18).

2. Replace blade if excessive ticking.

3. Cut and reweld blade, or replace blade (Page 18).

Machine or blade

bogs down in cut.

1. Feed rate too fast; blade speed too low.

2. Blade tension too low.

3. Blade gullets loading up with chips.

4. Blade dull, wanders, or gets pinched in cut.

5. Blade TPI too coarse.

1. Reduce feed rate (Page 23); increase blade speed

(Page 21).

2. Increase blade tension (Page 19).

3. Install blade with more suitable TPI or tooth style for

cooler cuts (Page 17).

4. Replace blade (Page 18) or replace guide bearings

(Page 30).

5. Use blade with at least 2 teeth contacting material

at all times (Page 17).

Cuts are not square,

or the intended

angle is incorrect.

1. Loose angle adjustable handle or vise

crank.

2. Blade not square to table.

1. Tighten loose angle adjustable handle or vise crank

(Page 23).

2. Adjust blade square to table (Page 31).

Blade dulls

prematurely, or

metal sticking to the

blade.

1. Incorrect feed/speed.

2. Blade gullets loading up with chips.

3. Blade improperly broken in.

1. Adjust feed rate (Page 23) or blade speed

(Page 21).

2. Use blade with larger gullets/fewer TPI (Page 17).

3. Replace blade (Page 18); complete blade break in

procedure (Page 20).

Blade wears on

one side or shows

overheating.

1. Blade guides worn or misadjusted.

2. Blade support inadequate.

3. Dull/incorrect blade.

1. Re-adjust (Page 18)/replace.

2. Tighten blade guide close to workpiece as possible.

3. Replace blade (Page 18).

Blade tracks

incorrectly, or

comes off wheels.

1. Feed rate too fast/wrong TPI.

2. Blade tension too low.

3. Blade bell-mouthed.

4. Blade guide bearings need adjustment.

5. Metal chip buildup on wheels.

1. Reduce feed rate/pressure (Page 23); decrease

blade TPI (Page 17).

2. Increase blade tension (Page 19).

3. Install new blade (Page 18); regularly remove

tension from blade when not in use (Page 19).

4. Adjust blade guide bearings (Page 30)

5. Clean metal chips from wheels.

Cuts are crooked. 1. Feed rate too fast; blade speed too low.

2. Guide bearings assembly too far from

workpiece.

3. Blade tension too low.

4. Blade dull.

5. Headstock is loose. Headstock pivot bolt/

bushings loose or worn.

1. Reduce feed rate (Page 23); increase blade speed

(Page 21).

2. Re-adjust (Page 18).

3. Increase blade tension (Page 19).

4. Replace blade (Page 18).

5. Remove/clean/lubricate/readjust bushing/bolt/nut.

Loading...

Loading...