K

Kerry RodriguezSep 13, 2025

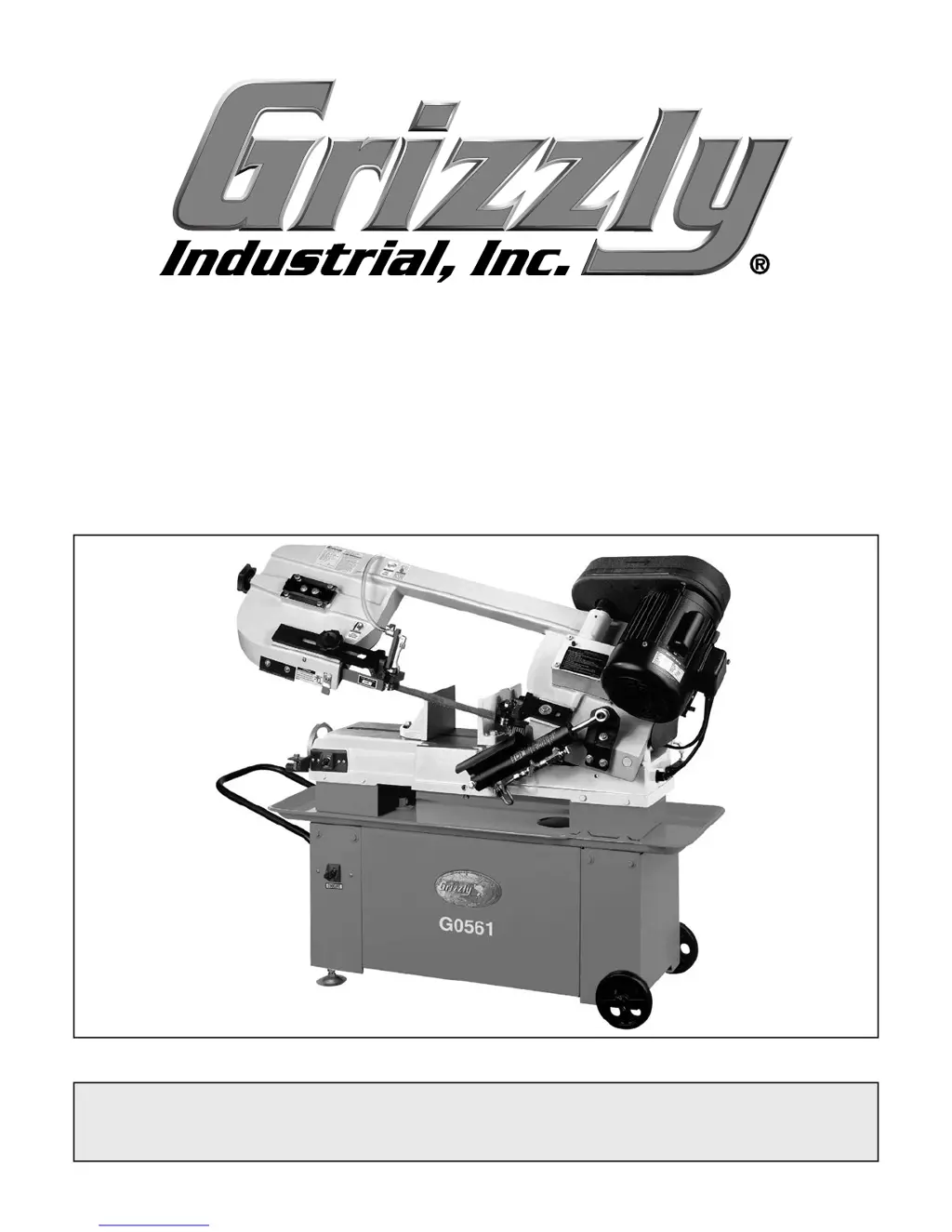

What to do if my Grizzly G0561 blade cuts into the table?

- DDavid CarrilloSep 13, 2025

If the blade on your Grizzly Saw cuts into the table or doesn't fully cut through the workpiece, it may be necessary to adjust the downfeed stop bolt.