Model G0561 (Mfd. Since 01/08)

-27-

Choosing Blade TPI

Selecting the right blade for the job depends on

a variety of factors, such as type, hardness, and

shape of the material being cut, machine capabil-

ity, and operator technique.

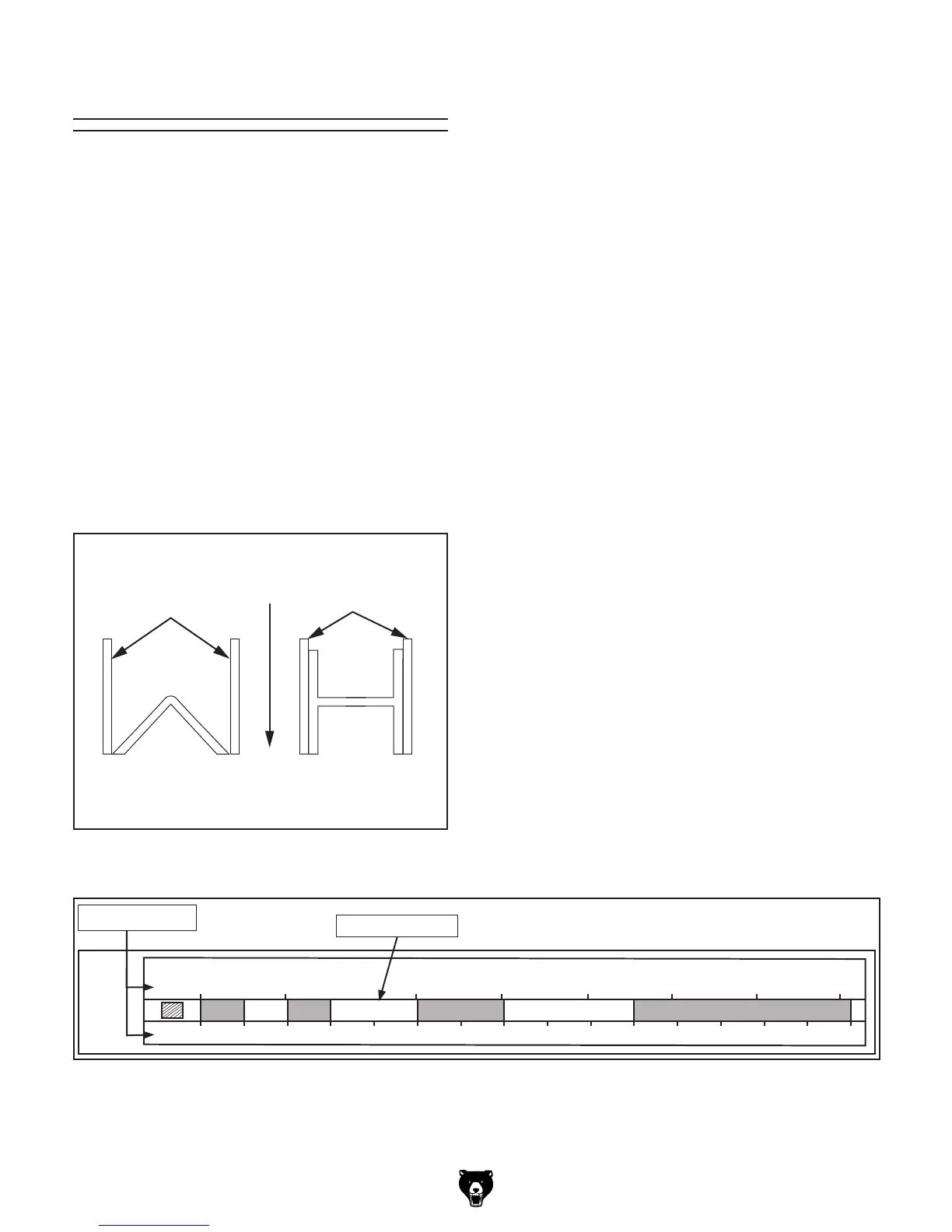

The chart in Figure 34 is a basic starting point

for choosing blade type based on teeth per inch

(TPI) for variable tooth pitch blades and for stan-

dard raker type bi-metal blades/HSS blades. As

a general rule, there should be at least 3 teeth in

contact with the workpiece at all times. However,

for exact specifications of bandsaw blades, con-

tact the blade manufacturer.

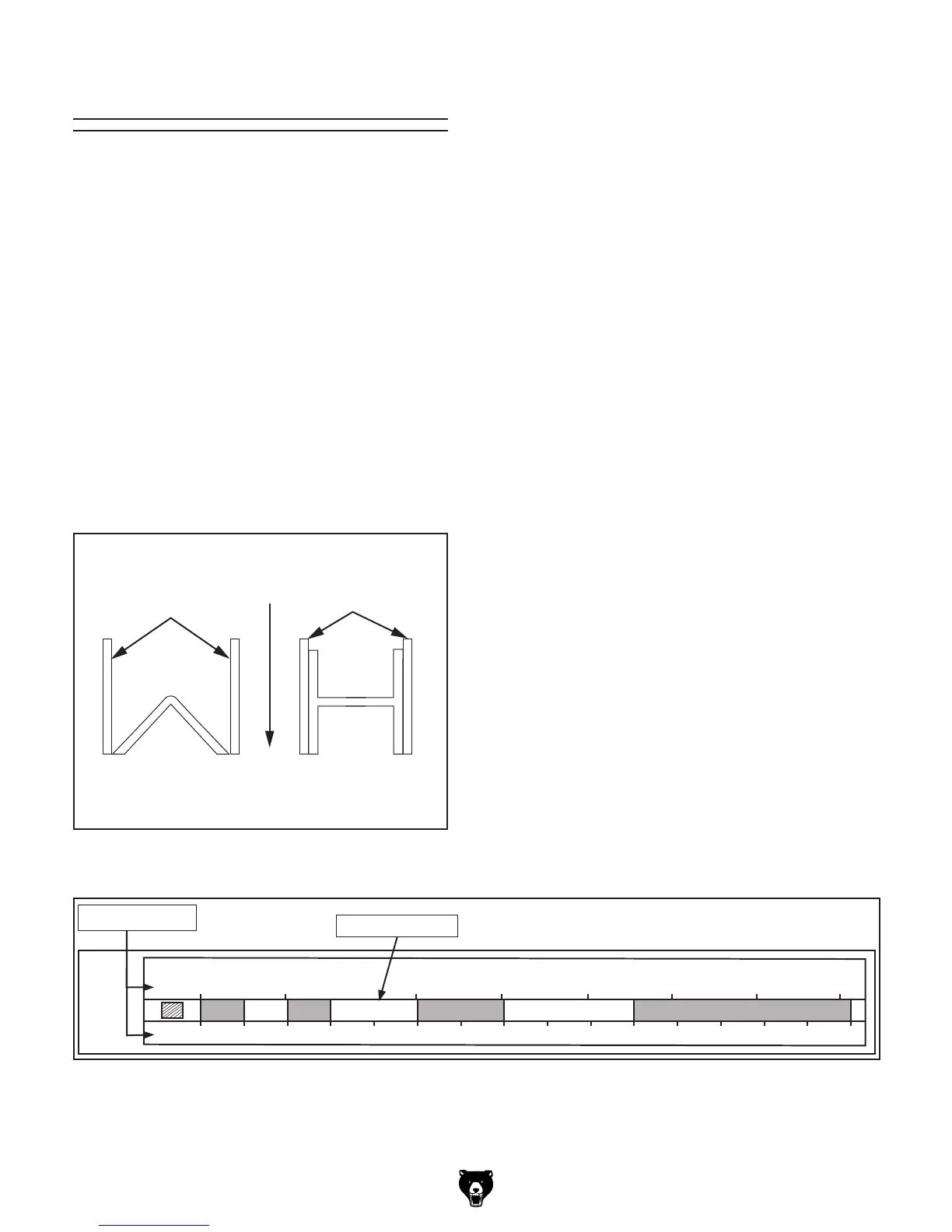

When cutting structural shapes such as angle iron

or I-beams, workpieces should be positioned to

maintain the same material width throughout the

cut, as illustrated in Figure 33.

To select correct blade TPI:

1. Measure material thickness. This measure-

ment is the length of cut taken from where the

tooth enters the workpiece, sweeps through,

and exits the workpiece.

2. Refer to "Material Width" row of blade selec-

tion chart in Figure 34 and read across to

find workpiece thickness you need to cut.

3. In the center row, find the TPI that corre-

sponds to the workpiece thickness.

Material Width

Figure 34. Material width and recommended teeth per inch.

TOOTH SELECTION

1

⁄

8

1

⁄

4

1

⁄

2

1 2 3 4 5 6 7 8 9 10 11 12

1

1

⁄

2

6 12 50 100 150 200 250 300

8-1210-14 6-10 5-8 3-4 2-3 1.4-2.5

mm

inch

Angle Iron

Positioned

For Cut

I-Beam

Positioned

For Cut

Vice Jaws Vice Jaws

Saw

Blade

Direction

(Side View)

Figure 33. Structural workpieces positioned in

vise for cut.

Teeth Per Inch

Loading...

Loading...