Model T28048 (Mfd. Since 06/17)

-33-

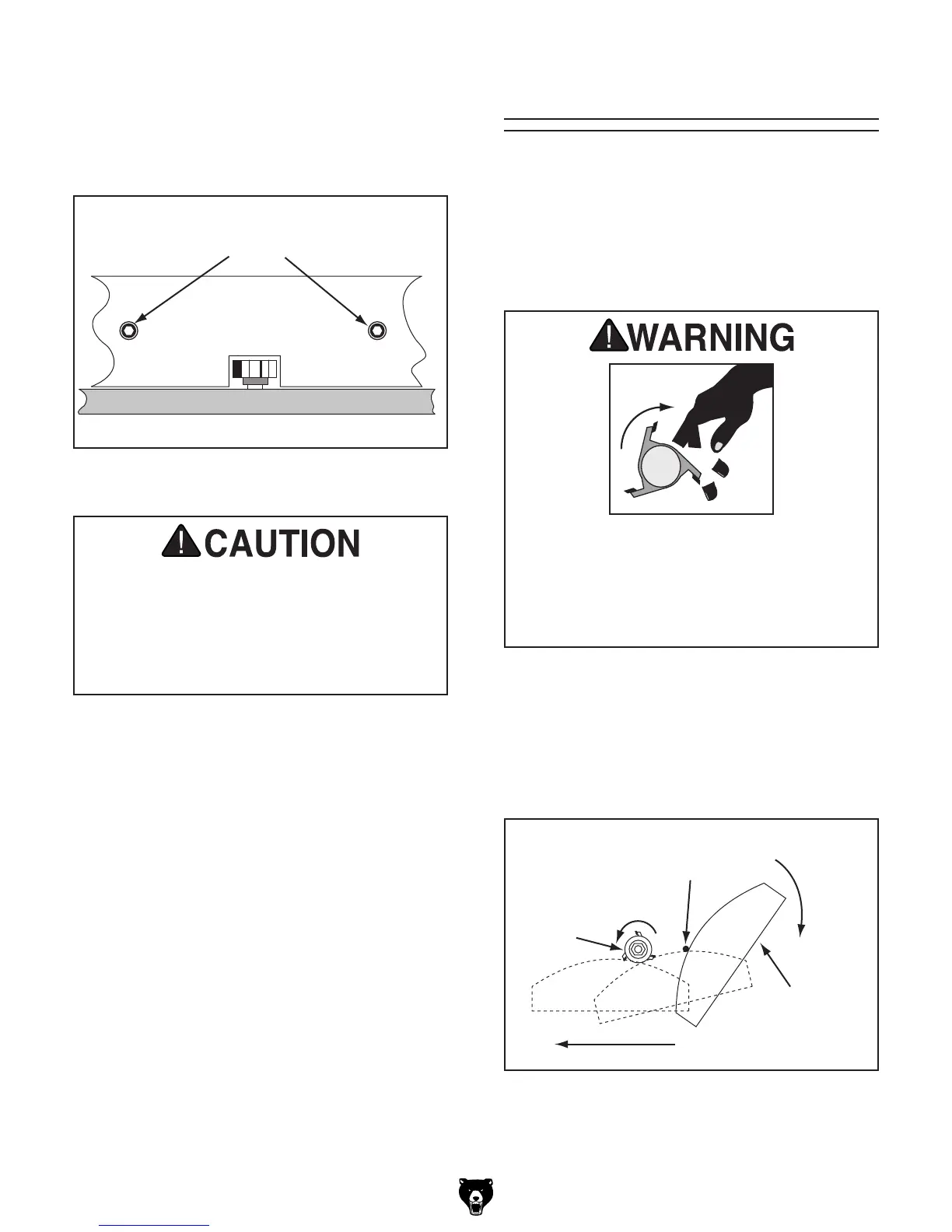

5. Create countersunk mounting holes in zero-

clearance fence board (see Figure 45) so

low-profile shoulder screws removed from

fence boards can be used to secure new

fence to fence assembly in the same manner.

ALWAYS use hold-downs or featherboards

and push sticks when shaping small or nar-

row stock. These devices keep your hands

away from spinning router bit and sufficient-

ly support stock to allow a safe and effective

cut, reducing risk of personal injury.

6. Secure zero-clearance fence board and

router bit guard to fence assembly, then

make sure fence is parallel to the table T-slot

(see Squaring Fence & Table on Page 28).

7. Check for proper clearance, connect router to

power, then make test cut to verify results.

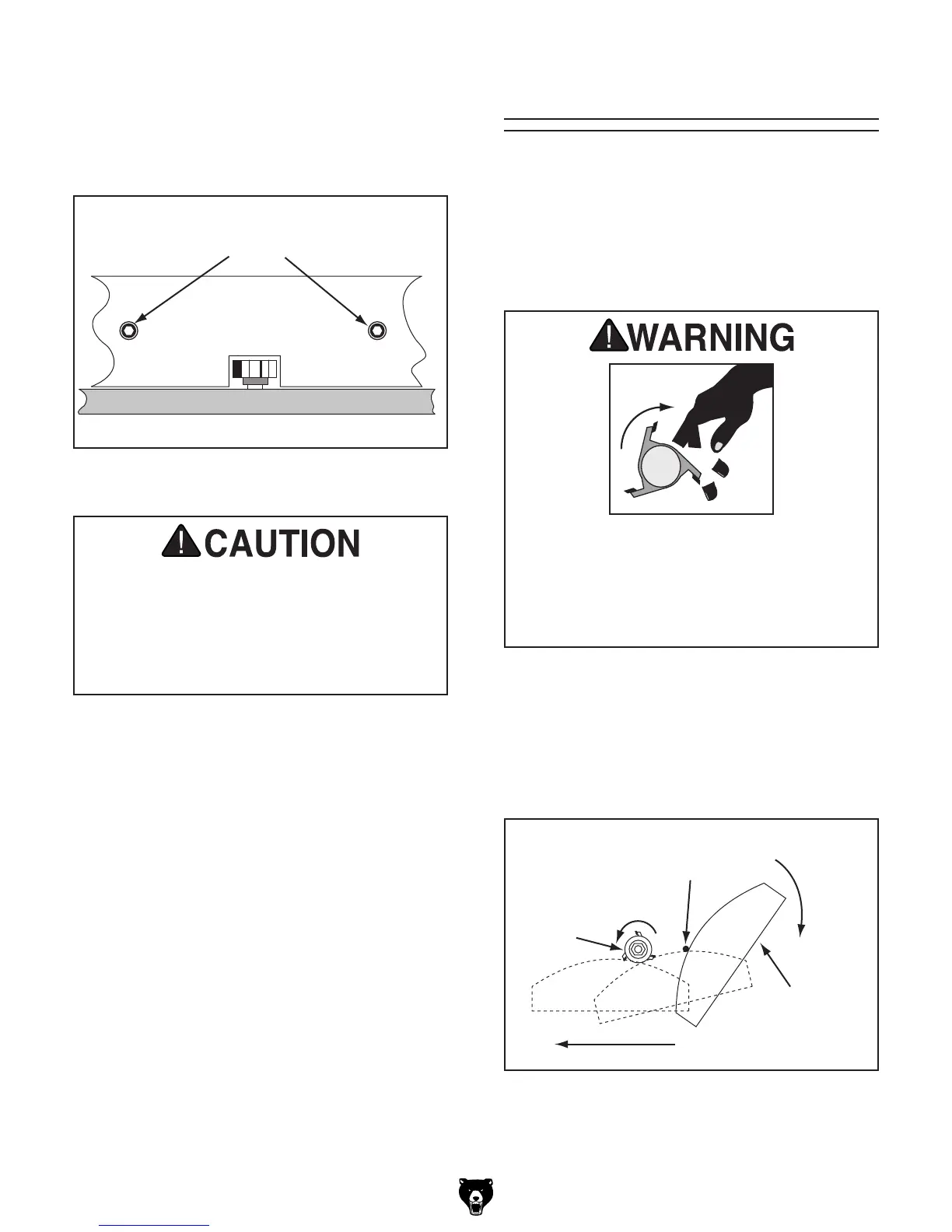

Free-Hand Routing

Irregular or free-hand routing takes a high degree

of skill and dexterity and is done without the pro-

tection and aid of the fence assembly and router

bit guard. The most dangerous part of free-hand

routing is beginning the cut, when the router bit

first contacts the workpiece. It tends to jerk or kick

back, presenting an injury hazard to the operator.

Free-hand or irregular routing greatly

increases the chance that the operator may

lose control of the workpiece, which could

result in serious personal injury. Therefore,

a starting pin or block and a custom guard

or workpiece holding jig MUST be used.

Workpiece

Feed Direction

Swing

Starting Pin

Rub

Collar

R

o

t

a

t

i

o

n

Figure 46. Illustration of free-hand routing using

a starting pin.

To reduce the likelihood of kickback when free-

hand routing, use the starting pin or block (see

Figures 46 & 47 for examples). This will allow

you to anchor and slowly pivot the workpiece into

the bit as the cut is started, making the operation

more stable and safe.

Zero-Clearance Fence Board

Table

Countersunk

Holes for Fasteners

Figure 45. Countersunk holes for mounting zero-

clearance fence board.

Loading...

Loading...