PART NUMBER 145702, REV. C (01/07)

CALL 888-994-7636 FOR TECHNICAL SUPPORT

12

INSTALLING, CLEANING AND TESTING

Water Connections(s)

No water connection is needed. The water will be poured directly

into the water cavity reservoir.

Make sure that the incoming water connection is made with a 3/4”

N.H. COLD water supply hose. Rigid pipe is not required. The

water pressure should be between 30 and 60 PSIG. Higher

pressures will require the use of a pressure regulator. Make sure

that all connections are tight with no leaks-no matter how small.

NOTICE: The quality of the water is a factor in the proper

performance of the steamer. The water supply should have a

minimum value of 30-40 parts per million of total dissolved solid

(TDS).

Drain Connection

The Vortex100 Connectionless Steamer should be manually

drained to the bottom containment pan supplied by the factory.

If the unit is connected to a drain, do not connect more than

two units to one drain line or pressure from one unit will effect

the second unit.

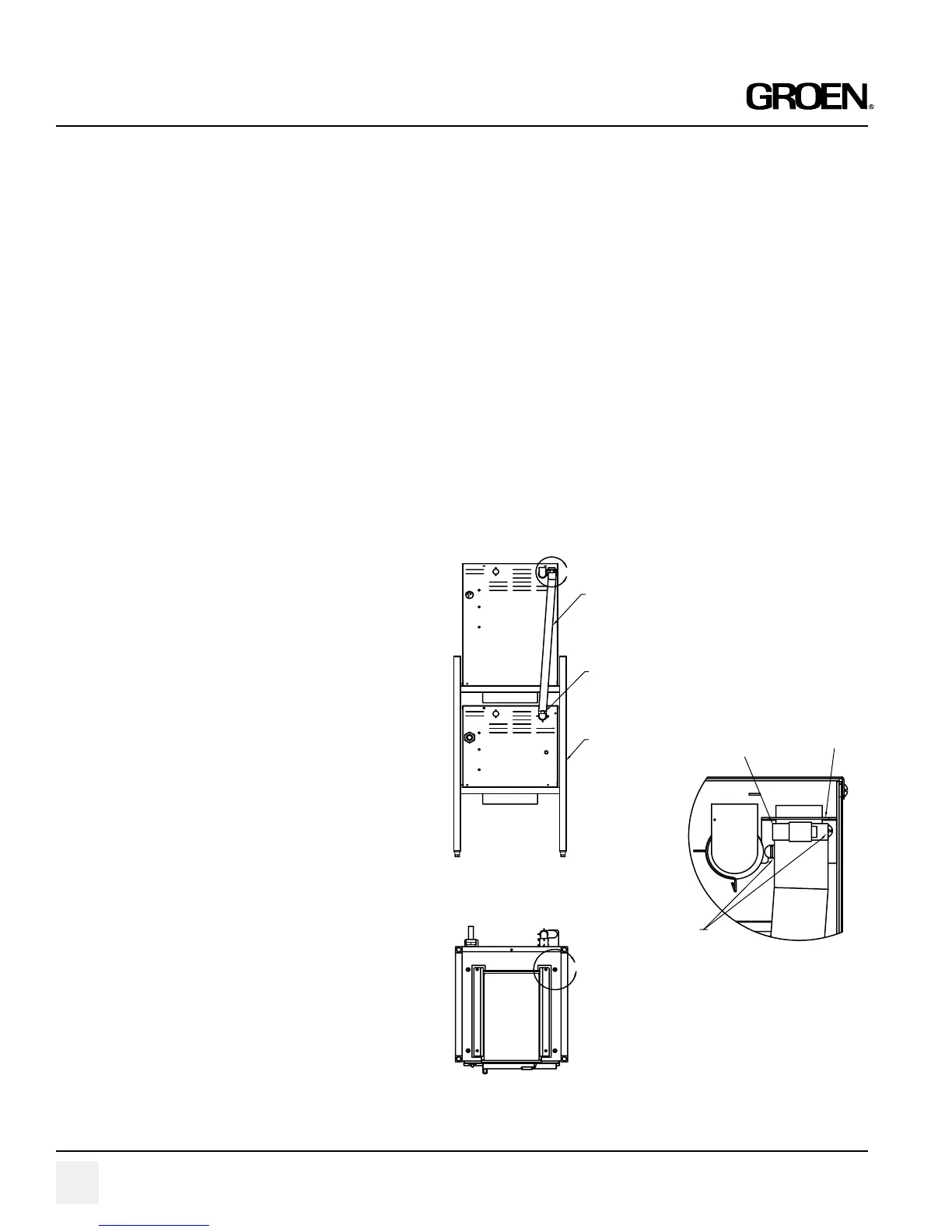

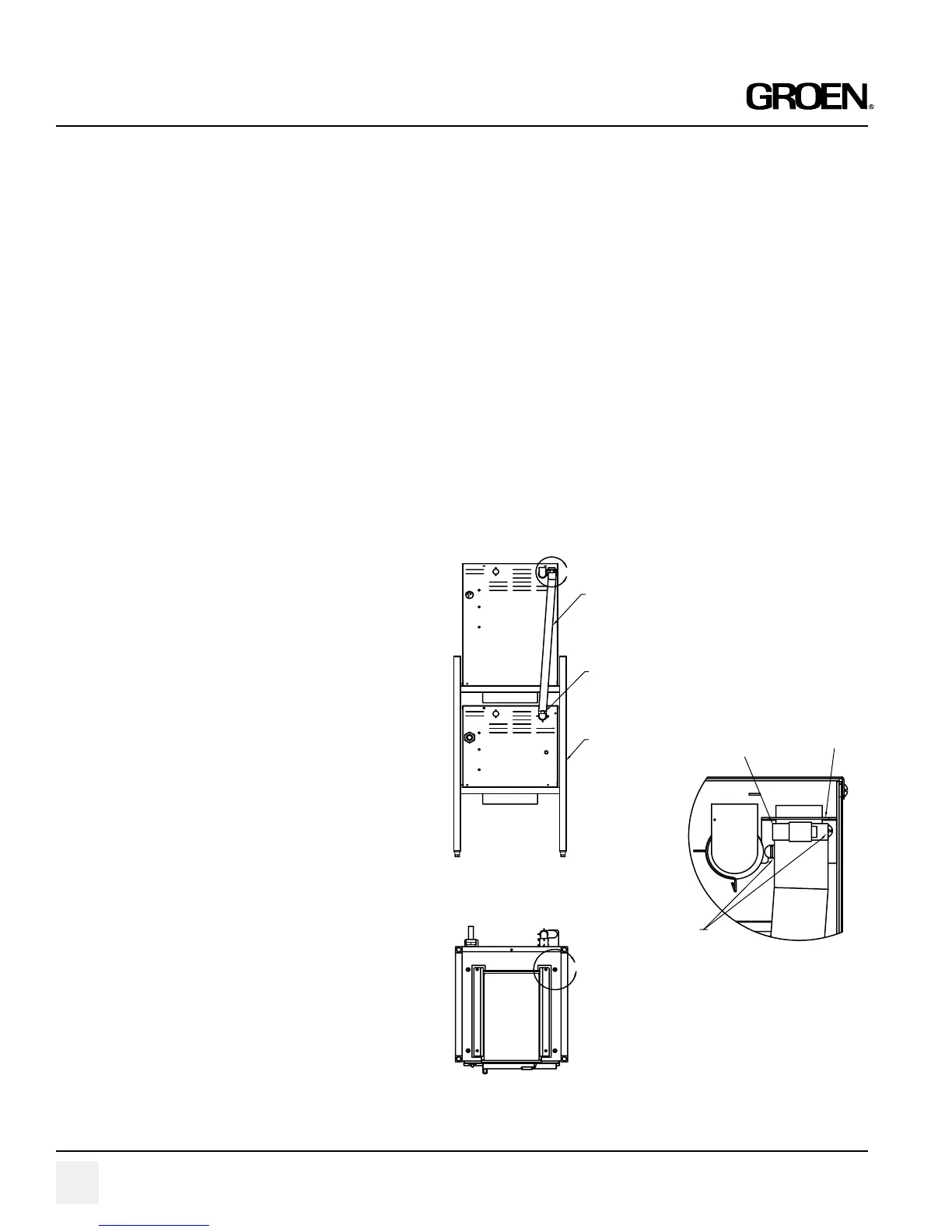

Steam Vent Assembly Instructions

Remove steam diverter assembly from literature bag which can

be found inside unit. Slide loose end as shown over unit steam

outlet, tighten worm gear clamp with flat head screw driver.

Be sure steam outlet is pointing in the upward position.

(Shown below)

Stacking Units Instructions

Remove drain containment pan from the bottom of unit(s).

Unscrew to remove adjustable legs from base of Vortex unit(s).

Unfasten nuts and bolts on stand platform(s). Place Vortex

unit(s) on stand platform. Align the (4) leg holes with the holes

in the platform. Secure Vortex units(s) to stand platform(s) using

bolts and washers provided with stand, see drawing below.

For double stack units only:

By loosening the left screw and removing the right screw provided,

mount steam exhaust bracket assembly to the back panel of the

top Vortex100 unit as shown in detail “B” of Figure 1 on the next

page. Attach the steam exhaust hose from the bottom Vortex

unit’s steam outlet tube to the top Vortex unit’s steam exhaust

bracket assembly using hose clamps provided as shown in figure

2 on the next page. (Note: Steam exhaust hose may need to be

cut to fit.)

FIGURE 1

FIGURE 2

DETAIL B

SCALE 1 : 1

DOUBLE

STACK

STAND P/N

142363

HOSE

CLAMPS

P/N 073259

HOSE

CLAMPS

P/N 073259

DOUBLE STACK

STEAM

EXHAUST HOSE

DOUBLE STACK

STEAM EXHAUST

BRACKET

ASSEMBLY

P/N 143243

10-32 SCREW

P/N 004173

• Units with Manual Fill

• Units with Auto-Fill

Drain Line Installation

Units with auto-fill or manual with drain kit

The drain line should not be less than:

1-1/2” - for single units

2” (5E) - for double stacked units

There must be a 2” air gap to the (non-pressurized) building

drain. Make sure that the drain is sloped AWAY and DOWN

from the steamer and that there are no obstruction in the line.

Failure to observe these requirements may cause a water trap

in the drain line and produce enough back pressure to prevent

proper cavity draining-resulting in condensate water leaking

from the door. Drain line must not NOT be made of plastic pipe.

It must be able to withstand boiling water.

Loading...

Loading...