10

5. Electrical connection

The electrical connection must be carried out by a

qualified electrician in accordance with local regula-

tions.

Note: Make sure that the supply voltage and fre-

quency correspond to the values stated on the

nameplate.

• Distance from the Conlift: 1 to 1.5 metres.

• The Schuko socket/socket with earth connection

and the boiler or cooling/air-conditioning system

must be connected to two different circuits. In

case of supply failure or undesired cut-out of the

cooling/air-conditioning system, this ensures that

the condensate, which continues to flow into the

collecting tank, is pumped away, thus causing no

damage.

• The Conlift incorporates a thermal switch, which

stops the motor in case of overload. When the mo-

tor has cooled to normal temperature, it will restart

automatically.

As standard, the Conlift is fitted with an alarm device

(buzzer). It is also possible to pass on the alarm indi-

cation via a potential-free contact.

See section 4.4.3 External alarm/potential-free con-

tact.

6. Start-up

Note: Start-up of the Conlift must be made in ac-

cordance with local regulations and accepted codes

of good practice.

1. Make sure that all hoses and connections are

tight.

2. Make sure that the motor cover (pos. 2) is

screwed on the Conlift, see section 8. Compo-

nents.

3. Switch on the electricity supply.

6.1 Checking the function

Pump operation:

Procedure:

1. Cut off the flow of condensate from the boiler or

cooling/air-conditioning system, or stop the flow

of condensate to the Conlift.

2. Pour the liquid of the collecting tank into a suita-

ble container.

3. Pull the inlet hose out of the collecting tank.

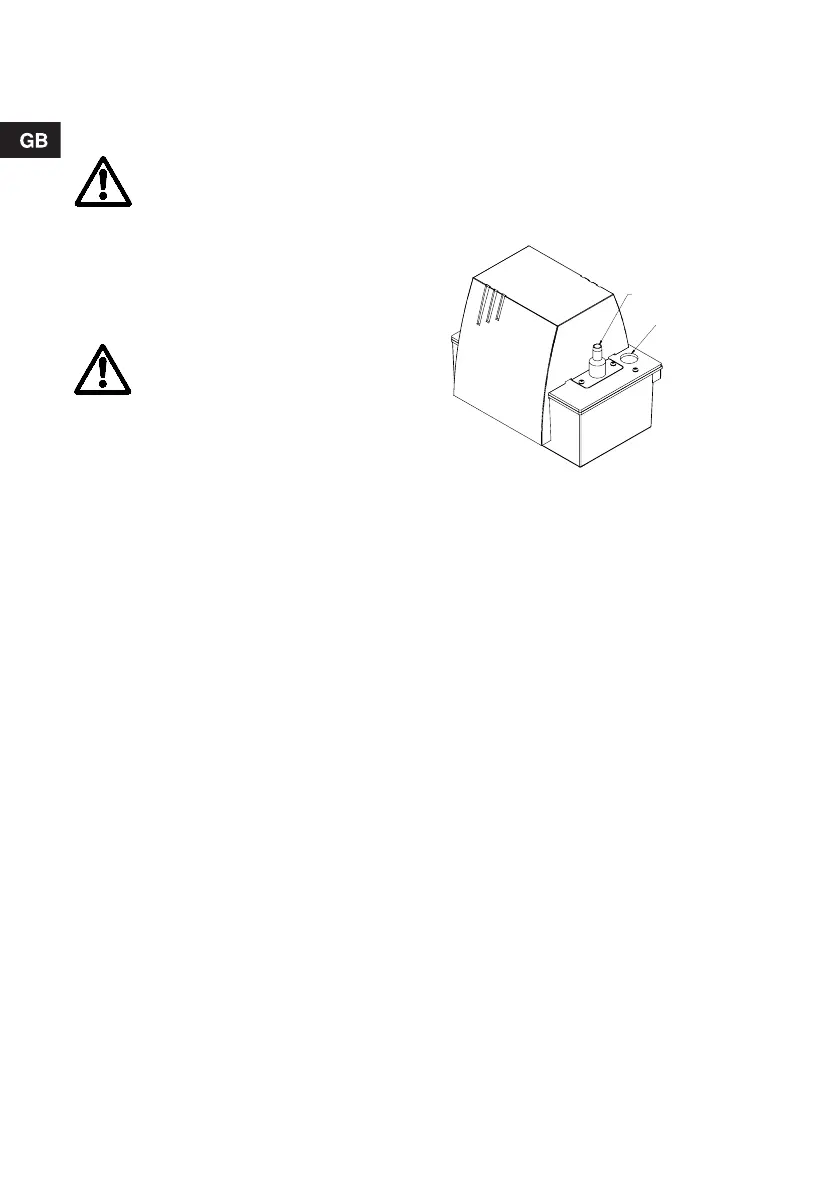

Fig. 7 Discharge stub and inlet opening

4. Pour approx. 1.7 litres of water into the collecting

tank through the inlet opening until the start level

is reached and the pump is started via pressure

switch 1.

5. Stop pouring water into the tank.

When the stop level is reached, the pump must

stop.

For stop/start/alarm levels, see fig. 1, section 3.

Function.

Alarm:

Continue the procedure:

6. To ensure that the alarm level is reached,

squeeze the discharge hose (or close the isolat-

ing cock, if any), and pour approx. 1.5 litres of

water into the collecting tank.

The pump is started via pressure switch 1.

7. Continue to pour water into the tank until the

alarm pressure switch (pressure switch 2) cuts

out. The buzzer is activated.

Note: The alarm pressure switch must release

the alarm (buzzer) before the water starts to run

out of the Conlift.

For stop/start/alarm levels, see fig. 1, section 3.

Function.

8. Stop pouring water into the tank and stop

squeezing the discharge hose. The alarm

(buzzer) stops. The pump continues to run.

When the stop level is reached, the pump stops.

Before starting work on the Conlift or

moving the Conlift, the electricity supply

must be switched off. It must be ensured

that the electricity supply cannot be

accidentally switched on.

As a precaution, the Conlift must be con-

nected to a Schuko socket or a socket with

earth connection.

It is recommended to fit the permanent in-

stallation with an earth leakage circuit

breaker (ELCB) with a tripping current

< 30 mA.

The Conlift must be connected to an exter-

nal mains switch with a minimum contact

gap of 3 mm in all poles.

TM02 7502 3603

Druckanschluss

Außen - ø10 mm

Zulaufanschluss

Innen - ø24 mm

Inlet opening

internal ø24 mm

Discharge stub

external ø12 mm

Loading...

Loading...