8

4.4 Connection of inlet and discharge

hoses

The hose supplied as an accessory can be used as

inlet and discharge hose.

• Attach the hose to the wall.

Distance between attachment points:

Approx. 30 cm.

• Make sure that the hose does not sag or is

squeezed.

• Avoid sharp bends. The bending radius of the

hose must be at least 60 mm.

• Run the inlet and discharge hoses in such a way

that they do not strain the Conlift.

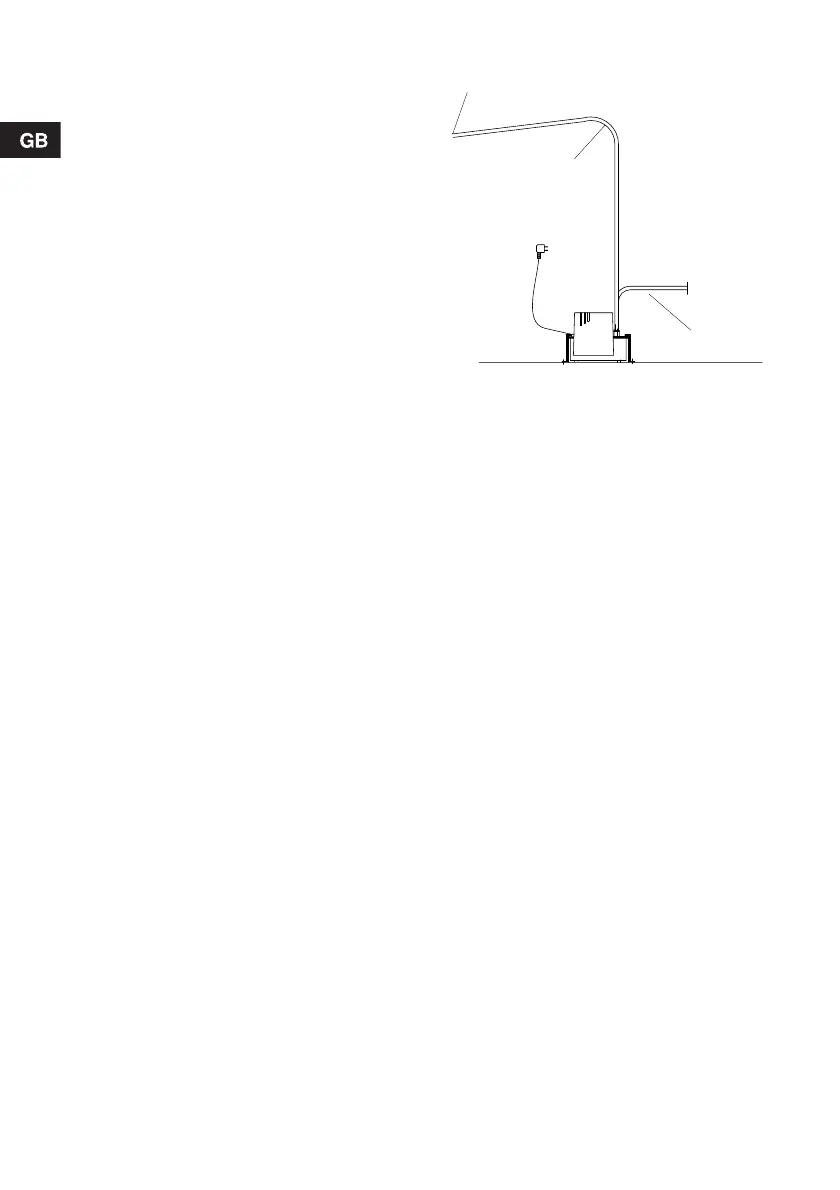

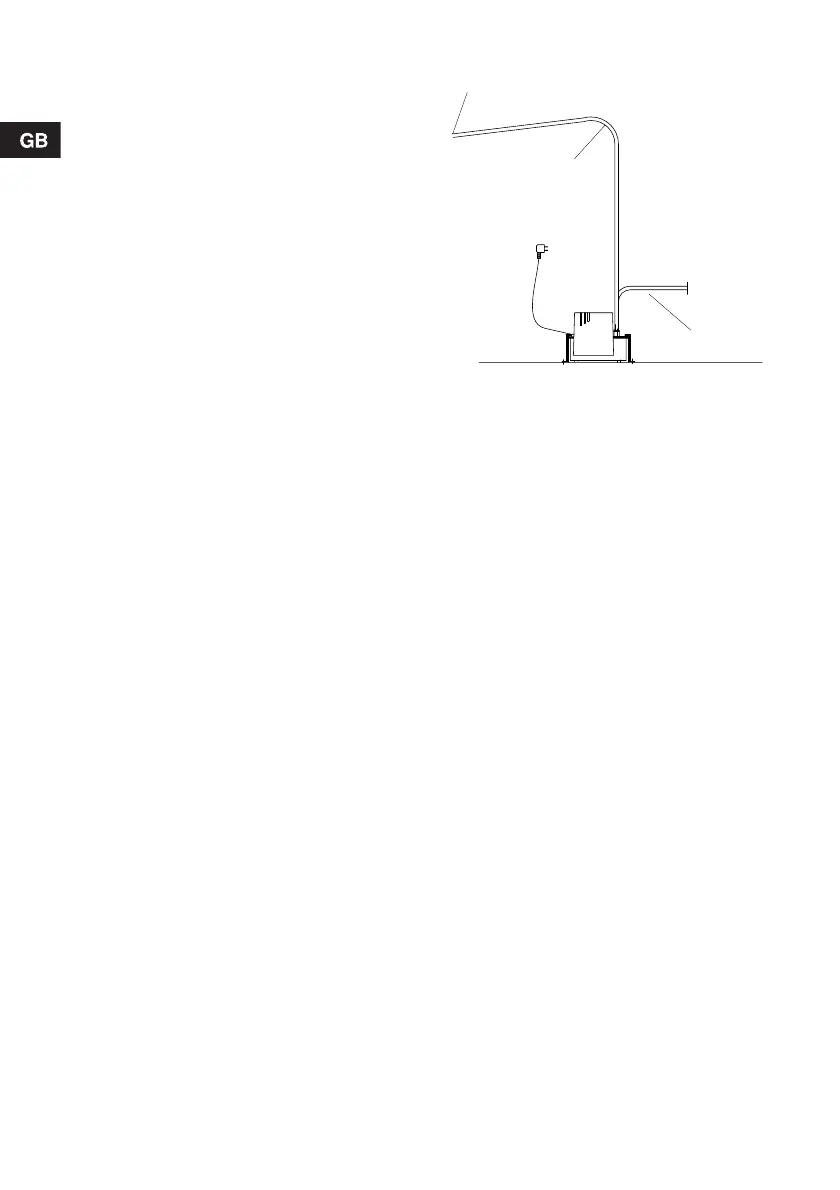

4.4.1 Inlet hose

• When running the inlet hose from the boiler or

cooling/air-conditioning system to the Conlift,

make sure that the condensate flows freely into

the collecting tank.

• Insert the inlet hose sufficiently deep into the tank

through the inlet opening, see fig. 7. It is recom-

mended to make a sloping cut to the hose.

4.4.2 Discharge hose

• Pass the discharge hose end over the discharge

stub (the grommet should not be lubricated with

grease), see fig. 7. Fasten the hose with the

clamp supplied with the lifting station.

• Take the discharge hose vertically up to the high-

est point from where the condensate can flow

freely into the sewage system or drain of the build-

ing.

• If the Conlift is positioned below sewer level, the

hose must have a return loop at the highest point.

The lower edge of the loop must be 10 to 20 cm

above sewer level (the sewer level usually corre-

sponds to the street level).

• At the highest point, a loop must be formed. The

bending radius of the hose must be at least

60 mm.

Fig. 5 Arrangement of hoses

TM02 7500 3603

R > 60 mm

R > 60 mm

Schlauchende zum

Freigefälleanschluss

R > 60 mm

Hose end to be connected to

sewage system or drain

R > 60 mm

Loading...

Loading...