English (GB)

7

3.4 Electrical connection, PM 1 and PM 2

• The electrical connection must be carried out in

accordance with local regulations and standards.

• The pressure manager must be connected to an

external mains switch with a contact gap of at

least 3 mm in all poles.

• As a precaution, the pressure manager must be

connected to a socket with earth connection.

• We recommend that you fit the permanent

installation with an earth leakage circuit breaker,

ELCB, with a tripping current < 30 mA.

3.4.1 Connecting pressure managers with cable

and plug fitted

Connect the pressure manager using the supplied

cable.

3.4.2 Connecting pressure managers with no

cable and plug fitted

1. Remove the operating panel of the pressure

manager.

2. Carry out the electrical connection as shown in

fig. 1 or 2 on page 35, depending on motor type.

3. Fit the operating panel securely with all four

mounting screws so that enclosure class IP65 is

maintained.

3.4.3 Alternative power supply

PM 1 and PM 2 can be powered by a generator or

other alternative power supplies, provided that the

requirements for the power supply are fulfilled. See

section 16.2 Technical data, PM 2.

4. Control functions

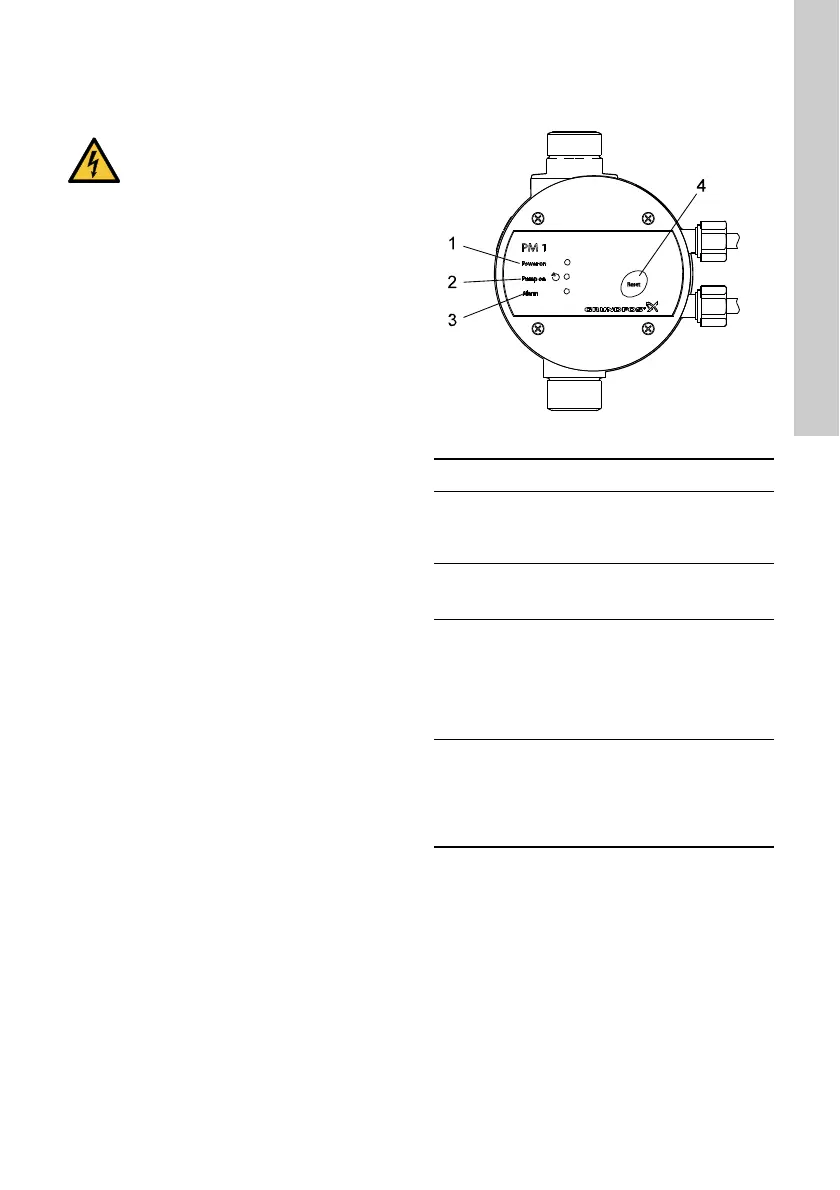

4.1 Operating panel, PM 1

Fig. 7 Operating panel, PM 1

DANGER

Electric shock

- Death or serious personal injury

- Before making any connections in the

pressure manager, make sure that the

power supply has been switched off and

that it cannot be accidentally switched

on.

TM03 9360 1708

Pos. Description Function

1"Power on"

The green indicator light is

permanently on when the

power supply has been

switched on.

2 "Pump on"

The green indicator light is

permanently on when the

pump is running.

3"Alarm"

The red indicator light is

permanently on or flashes

when the pump has

stopped due to an operating

fault.

See section 15.1 Fault

finding, PM 1.

4[Reset]

The button is used for

• resetting fault indications

• enabling and disabling of

the anti-cycling function.

See section 9.3 Power

supply failure.

Loading...

Loading...