English (GB)

5

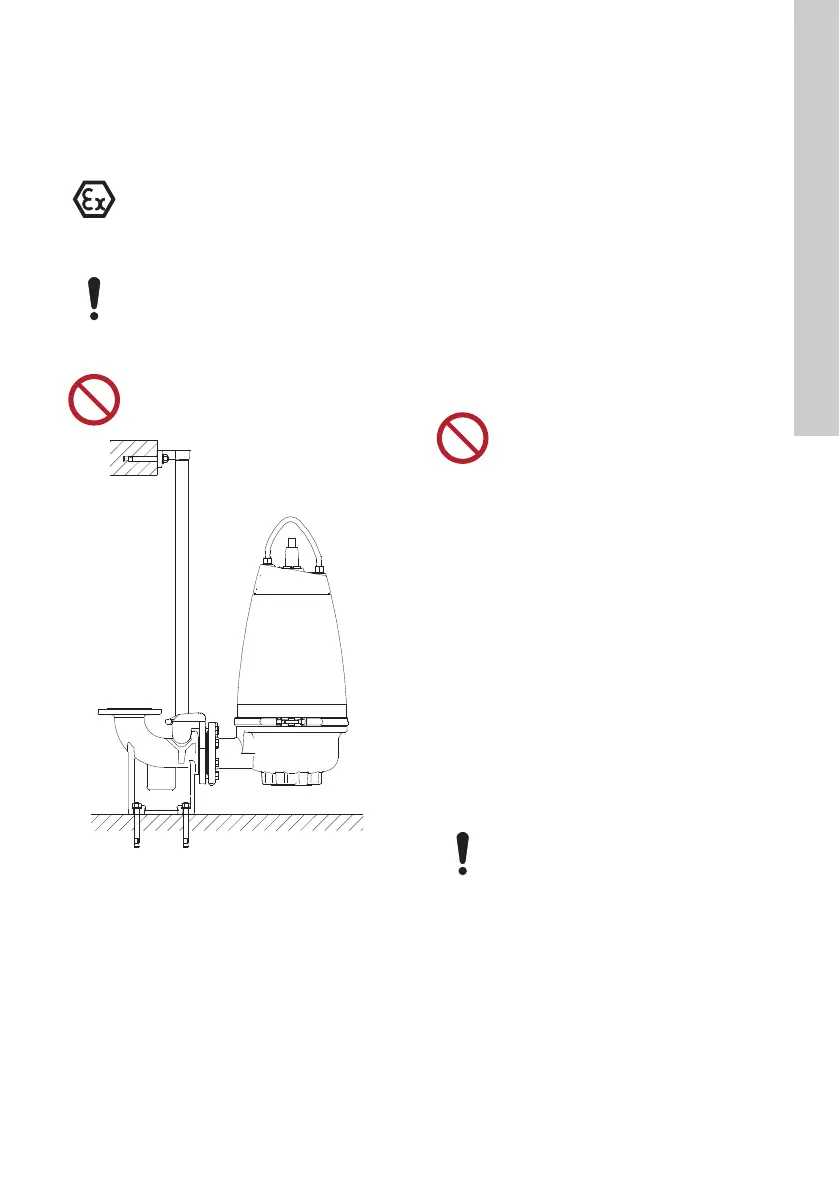

3.1.2 Submerged installation on auto coupling

Pumps for permanent installation can be installed on

a stationary auto-coupling guide rail system. The

auto-coupling system facilitates maintenance and

service as the pump can easily be lifted out of the pit.

See fig. 1.

Fig. 1 Submerged pump on auto coupling

Proceed as follows:

1. Drill mounting holes for the guide rail bracket on

the inside of the pit and fasten the guide rail

bracket provisionally with two screws.

2. Place the auto-coupling base unit on the bottom

of the pit. Use a plumb line to establish the

correct positioning. Fasten the auto coupling with

expansion bolts. If the bottom of the pit is

uneven, the auto-coupling base unit must be

supported so that it is level when being fastened.

3. Assemble the outlet pipe in accordance with the

generally accepted procedures and without

exposing the pipe to distortion or tension.

4. Place the guide rails on the auto-coupling base

unit and adjust the length of the rails accurately

to the guide rail bracket at the top of the pit.

5. Unscrew the provisionally fastened guide rail

bracket. Insert the upper guide rail bracket into

the guide rails. Fasten the guide rail bracket on

the inside of the pit.

6. Clean out debris from the pit before lowering the

pump into the pit.

7. Fit the guide claw to the outlet port of the pump.

8. Slide the guide claw of the pump between the

guide rails and lower the pump into the pit by

means of a chain secured to the lifting bracket of

the pump. When the pump reaches the auto-

coupling base unit, the pump will automatically

connect tightly.

9. Hang up the end of the chain on a suitable hook

at the top of the pit and in such a way that the

chain cannot come into contact with the pump

housing.

10. Adjust the length of the power cable by coiling it

up on a relief fitting to ensure that the cable is not

damaged during operation. Fasten the relief

fitting to a suitable hook at the top of the pit.

Make sure that the cable is not sharply bent or

pinched.

11. Connect the power cable.

Before beginning installation procedures,

make sure that the atmosphere in the pit is

not potentially explosive.

Make sure that the pipes are installed

without the use of undue force. Do not

allow loads from the weight of the pipes to

be carried by the pump. We recommend

that you use loose flanges to ease the

installation and to avoid pipe tension at

flanges and bolts.

Do not use elastic elements or bellows in

the pipes; never use these elements as a

means to align the pipes.

TM02 8404 0616

The guide rails must not have any axial

play as this would cause noise during

pump operation.

The free end of the power cable must not

be submerged, as water may penetrate

through the cable into the motor.

Loading...

Loading...