English (GB)

7

3.1.4 Dry installation

In dry installations, the pump must be installed

permanently outside the pit.

The motor is totally enclosed and watertight.

Consequently, it will not be damaged in case the

installation site is flooded.

Precautions

• As the pump is installed outside the pit, make

sure that the liquid level in the pit is high enough

to ensure sufficient NPSH.

• Size the inlet line according to the length and the

desired pump performance. A possible difference

in level between the pit and the pump inlet must

also be taken into account.

• Support the pipes so that no strain or other

mechanical influences are transmitted to the

pump. We recommend that you install expansion

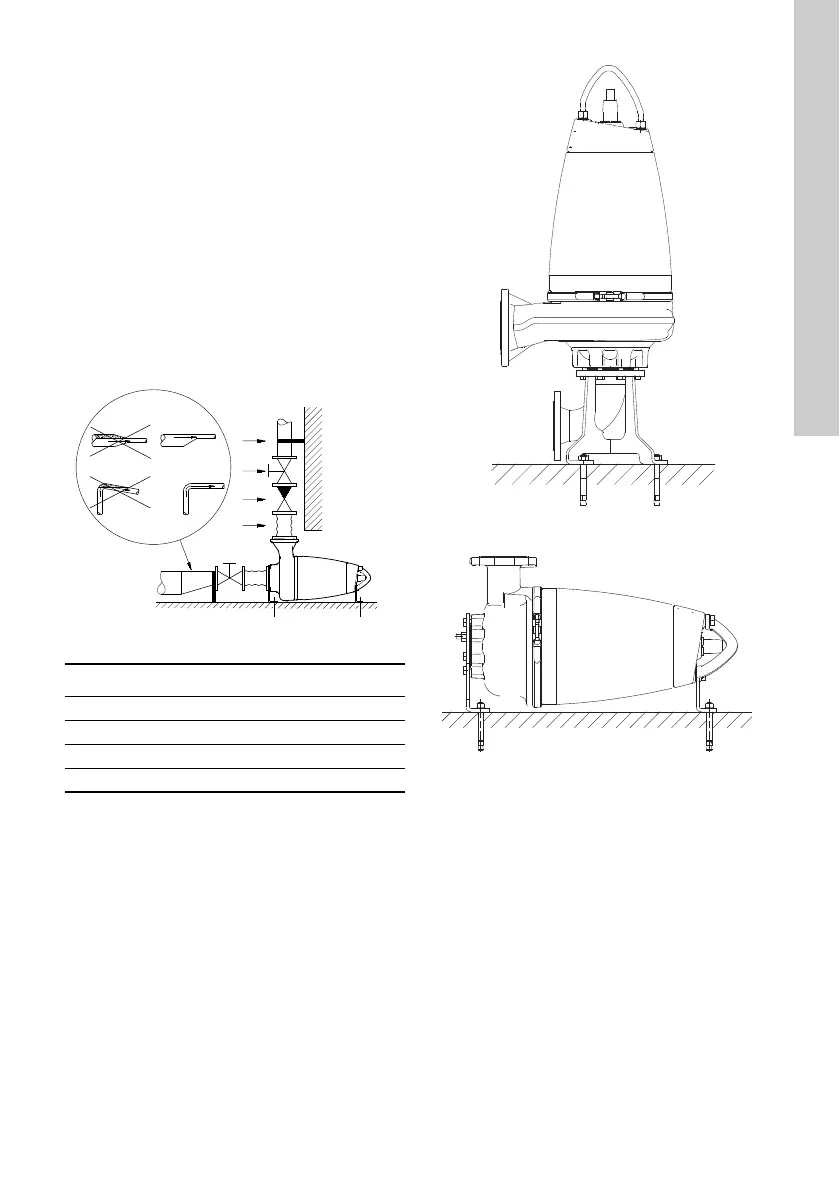

joints and pipe hangers. See fig. 3.

Fig. 3 Horizontal dry installation with brackets

• If a reducer is fitted between the inlet line and the

pump, it must be of the eccentric type. The

reducer must be fitted so that the straight edge is

upwards to avoid air pockets in the inlet line. Air

in the inlet line may cause cavitation. See fig. 3.

• Install the pump on a separate foundation, for

instance a concrete foundation. The weight of the

foundation must be approx. 1.5 times the weight

of the pump. To prevent vibrations from being

transmitted to the building and pipes, we

recommend that you place the pump on vibration

absorbing material.

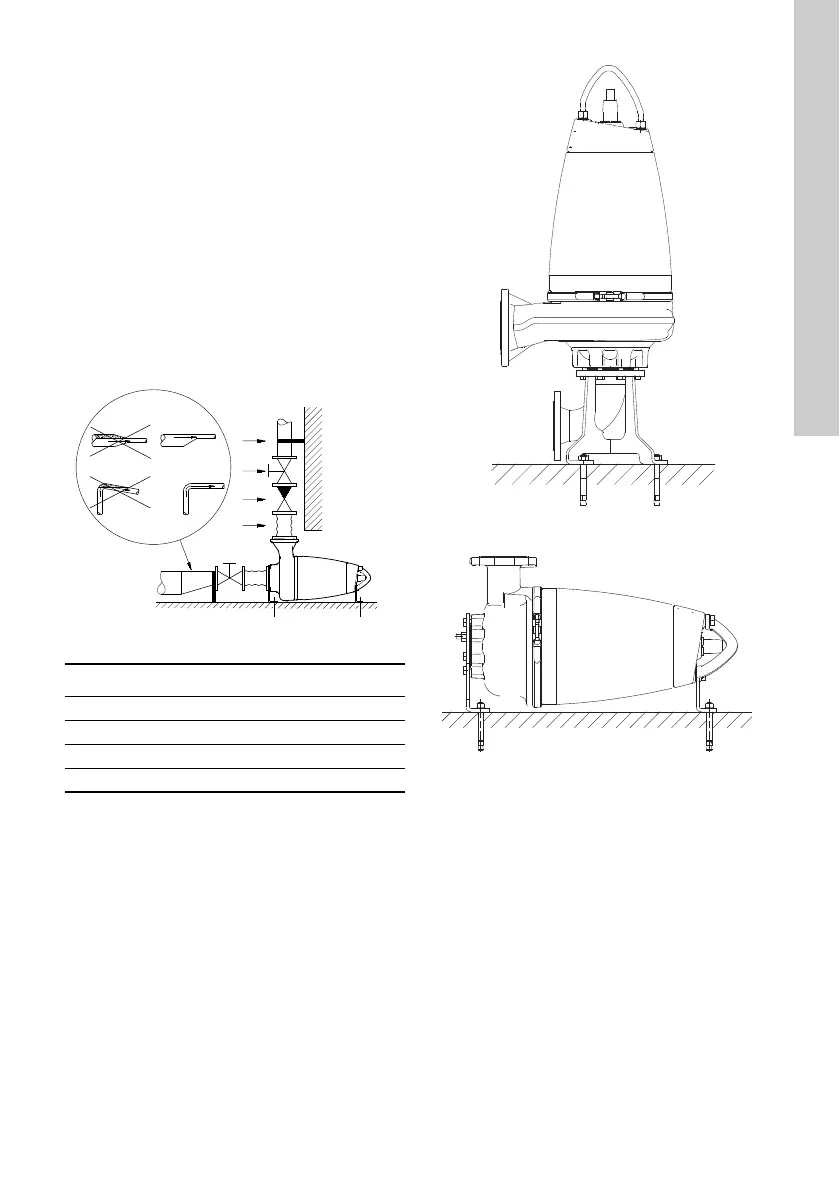

Fig. 4 Vertical dry installation on a base stand

Fig. 5 Horizontal dry installation with brackets

TM02 8399 5103

Pos. Description

1 Expansion joint

2 Non-return valve

3 Isolating valve

4 Pipe hanger

TM02 8401 0616

TM02 8402 0616

Loading...

Loading...