English (GB)

22

8.2 Pump controllers

SL1 and SLV pumps can be connected to the

following Grundfos pump controllers for level control:

LC controllers are for one-pump-installations and

LCD controllers are for two-pump installations.

• LC 107 and LCD 107 with air bells

• LC 108 and LCD 108 with float switches

• LC 110 and LCD 110 with electrodes

• LC 231 or LC 241

• Grundfos DC and DCD.

For further information on controllers, please see the

installation and operating instructions for the

selected controller or go to

www.grundfos.com.

8.3 Thermal switch, Pt1000 and PTC

thermistor

All SL1 and SLV pumps have thermal protection

incorporated in the stator windings.

Pumps without sensor

Pumps without sensor have a thermal switch or a

PTC thermistor. Via the pump controller safety

circuit, the thermal switch will stop the pump by

breaking the circuit in case of overtemperature

(approximately 150 °C). The thermal switch will

reclose the circuit after cooling. For pumps equipped

with a PTC thermistor, connect the thermistor to

either the PTC relay or the I/O module to break the

circuit at 150 °C.

The maximum operating current of the thermal

switch is 0.5 A at 500 VAC and cos φ 0.6. The switch

must be able to break a coil in the supply circuit.

Pumps with WIO sensor

Pumps with WIO sensor have either a thermal switch

and a Pt1000 sensor or a PTC thermistor in the

windings, depending on the installation site.

Via the pump controller safety circuit, the thermal

switch or the thermistor will stop the pump by

breaking the circuit in case of overtemperature

(approximately 150 °C). The thermal switch or the

thermistor will reclose the circuit after cooling.

The maximum operating current of both the Pt1000

and the thermistor is 1 mA at 24 VDC.

Non-explosion-proof pumps

When closing the circuit after cooling, the thermal

protection can restart the pump automatically via the

controller. Pumps from 4 kW and up sold in Australia

and New Zealand are fitted with a PTC thermistor.

Explosion-proof pumps

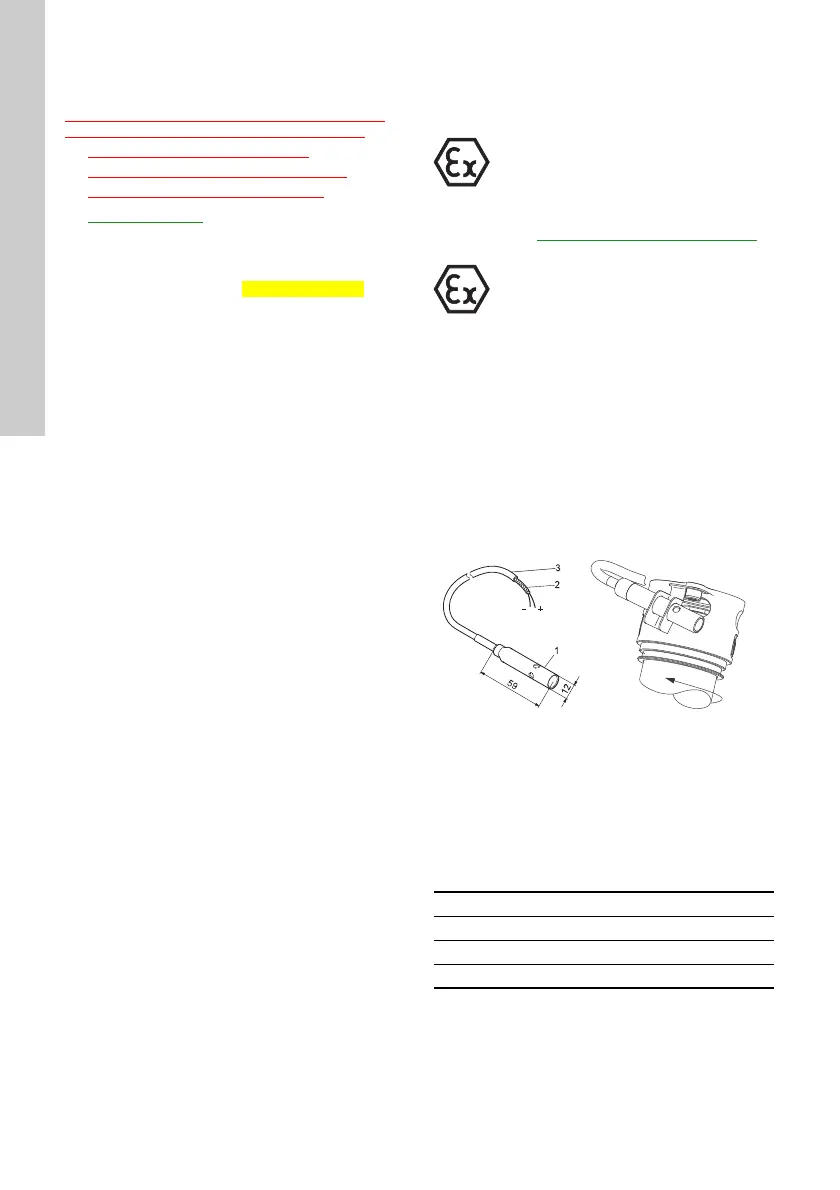

8.4 WIO sensor (water-in-oil sensor)

The WIO sensor measures the water content in the

oil and converts the value into an analogue current

signal. The two sensor conductors are for power

supply and for carrying the signal to the IO 113. The

sensor measures the water content from 0 to 20 %. It

also sends a signal if the water content is outside the

normal range (warning), or if there is air in the oil

chamber (alarm). The sensor is fitted in a stainless-

steel tube for mechanical protection.

Fig. 10 WIO sensor

8.4.1 Fitting the WIO sensor

Fit the sensor next to one of the shaft seal openings.

See fig. 10. The sensor must be tilted into the

motor's direction of rotation to ensure that oil is led

into the sensor. Make sure that the sensor is

submerged in the oil.

8.4.2 Technical data

See also the installation and operating instructions

for IO 113 on www.grundfos.com.

The thermal protection of explosion-proof

pumps must not restart the pump

automatically. This ensures protection

against overtemperature in potentially

explosive environments. In pumps with

sensor this is done by removing the short

circuit between terminals R1 and R2 in the

IO 113. See Electrical data in the

installation and operating instructions for

IO 113 (net.grundfos.com/qr/i/98097396)

.

The separate motor-protective circuit

breaker or controller must not be installed

in potentially explosive environments.

TM04 5238 2909 - TM03 1164 1105

Input voltage: 12-24 VDC

Output current: 3.4 - 22 mA

Power input: 0.6 W

Ambient temperature: 0-70 °C

Loading...

Loading...