English (GB)

23

8.5 Moisture switch

All pumps are fitted with a moisture switch as

standard with the moisture switch being connected

via the supply cable, see section 8. Electrical

connection, and connected to a separate circuit

breaker.

The moisture switch is positioned in the bottom of

the motor. If there is moisture in the motor, the switch

will break the circuit and send a signal to the IO 113.

The moisture switch is non-reversing and must be

replaced after use.

The moisture switch is connected to the control

cable, and it must be connected to the safety circuit

of the separate pump controller. See section

8. Electrical connection.

8.6 IO 113

IO 113 provides an interface between a Grundfos

wastewater pump equipped with sensors and the

pump controller(s). The most important sensor status

information is indicated on the front panel.

One pump can be connected to one IO 113 module.

Together with the sensors, the IO 113 provides a

galvanic isolation between the motor voltage in the

pump and the connected controller(s).

IO 113 can do the following as standard:

• Protect the pump against overheating.

• Monitor the status of these items:

– motor winding temperature

– leakage (WIO)

– moisture in pump.

• Measure the stator insulation resistance.

• Stop the pump in case of alarm.

• Remotely monitor the pump via RS-485

communication (Modbus or GENIbus).

• Control the pump via a frequency converter.

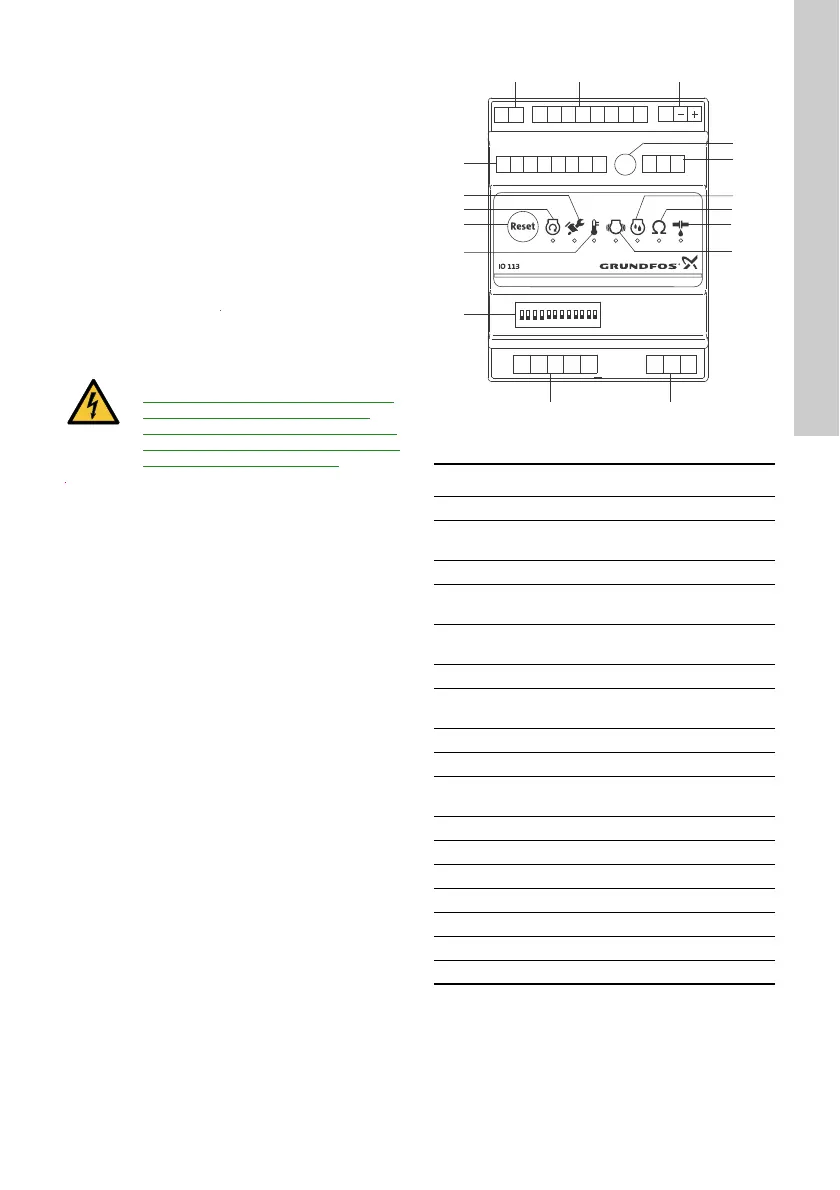

Fig. 11 IO 113 module

CAUTION

Electric shock

Minor or moderate personal injury

- The motor-protective circuit breaker of

the pump controller must include a

circuit which automatically disconnects

the power supply in case the protective

circuit for the pump is opened.

TM05 1881 3811

Pos. Description

1 Terminals for alarm relay

2

Terminals for analog and digital inputs and

outputs

3 Terminals for supply voltage

4

Potentiometer for setting the warning limit

of stator insulation resistance

5

Terminals for RS-485 for GENIbus or

Modbus

6 Indicator light for moisture measurement

7

Indicator light for stator insulation

resistance

8 Indicator light for leakage (WIO)

9 Indicator light for vibration in pump

10

Terminals for measurement of stator

insulation resistance

11 Terminals for connection of pump sensors

12 DIP switch for configuration

13 Indicator light for motor temperature

14 Button for resetting alarms

15 Indicator light for motor running

16 Indicator light for service

17 Terminals for digital outputs

PET1 T2

G1 A1 G2 A2 K1 K2 R1 R2

D1 D2 D3 D4 D5 D6 D7 D8

P1 P2 P3 P4 P5

AYB

I1 I2 I3

ON DIP

12345678910

11 1 2

12 3

4

5

6

7

8

9

1011

Loading...

Loading...